Waste water treatment system and method for power plant

A technology for treating system and power plant wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problem of unfavorable reuse and the difficulty of crystalline salt composition to ensure stable industrial salt quality. Standard, low quality of crystalline salt, etc., to avoid the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

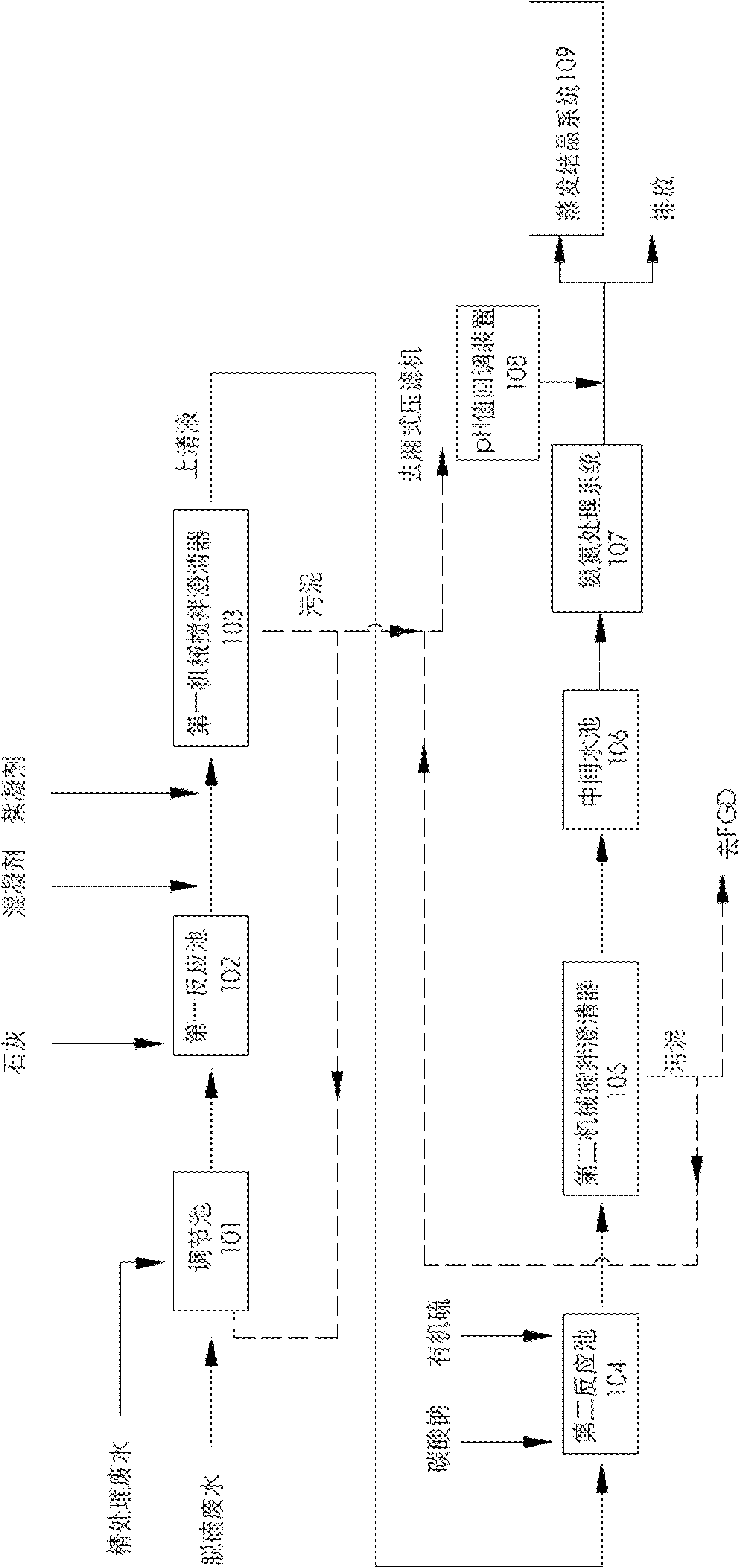

[0042] Such as figure 1 Shown is the first embodiment of the power plant wastewater treatment system of the present invention, which includes a connected pretreatment system, an ammonia nitrogen treatment system 107 and an evaporation crystallization system 109 . The ammonia nitrogen treatment system 107 is connected between the pretreatment system and the evaporation crystallization system 109, and is connected to the wastewater treated by the pretreatment system to remove ammonia nitrogen to reduce the ammonia nitrogen content in the wastewater.

[0043] The pretreatment system can adopt the pretreatment system such as Chinese invention patent No. ZL200820235234.4 and invention patent application No. 2008102412871; of course, other similar ones that can remove most of SS, heavy metals and Mg in power plant wastewater can also be used 2+ , F - , and the pretreatment system of sulfate radicals for treatment. The pretreatment system includes a regulating tank 101, a first rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com