Method for purifying reverse osmosis concentrated water with active carbon-membrane separation countercurrent absorption

A technology of reverse osmosis concentrated water and membrane separation, which is applied in adsorption water/sewage treatment, osmosis/dialysis water/sewage treatment, etc. Balanced and sustainable development, broad application prospects, and the effect of reducing potential hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

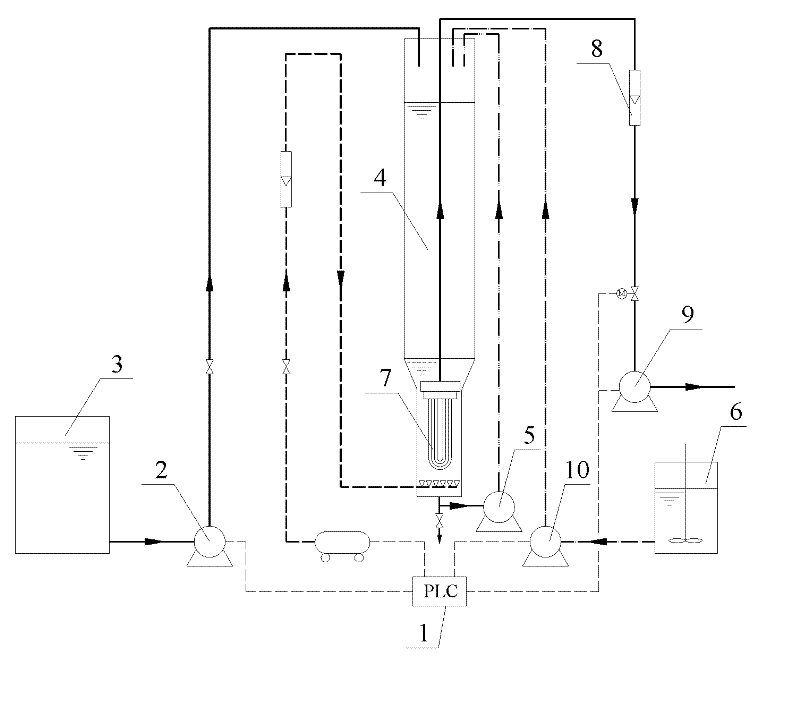

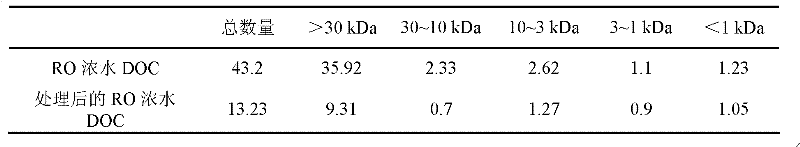

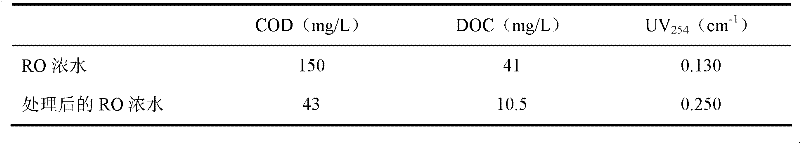

[0022] Example: Process treatment of RO concentrated water in petrochemical enterprises. The process flow of the small test is shown in the accompanying drawing. The material of the hollow fiber membrane module is polyvinylidene fluoride, the nominal pore size is 0.2μm, and the membrane area is 0.25m 2 . The design flow rate is 3.0L / h, and the total residence time in the membrane reactor is 1h. The membrane separator adopts the method of aeration stirring and circulation backflow, the air-water ratio is 8:1, and the water outlet of the microfiltration membrane is intermittently discharged by constant flow pump suction. The PAC in the membrane reactor was emptied every 2 days.

[0023] Embodiment adopts the experimental device as shown in the figure to carry out, adopts the mode of operation of circulation, and the concrete operation step of each circulation is:

[0024] (1) Under the control of PLC (programmable logic controller) 1, the lift pump 2 extracts RO concentrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com