Plastic granulating waste gas purifying device

A waste gas purification device and granulation technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high processing cost, unreasonable equipment structure, and unsatisfactory processing effect, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

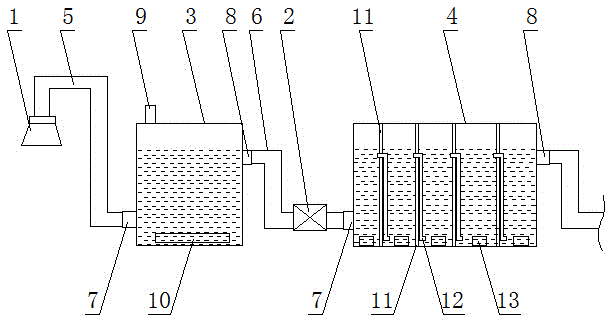

[0015] The plastic granulation waste gas purification device includes a gas collecting hood 1 , a vacuum pump 2 , a primary purified water tank 3 and a secondary purified water tank 4 . The bottom ends of one side of the first-level purified water tank 3 and the second-level purified water tank 4 are respectively provided with air inlets 7; . The air collecting hood 1 communicates with the primary purified water tank 3 through the primary communicating pipe 5 and the air inlet 7 . The top of the primary purified water tank 3 is provided with a water injection port 9 ; the bottom of the primary purified water tank 3 is provided with a sediment cleaning port 10 .

[0016] The primary purified water tank 3 communicates with the air inlet 7 of the secondary purified water tank 4 through the air outlet 8 through the secondary connecting pipe 6 . A vacuum pump 2 is installed on the secondary connecting pipe 4 . The tank body of the secondary purified water tank 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com