Low-temperature SCR (selective catalytic reduction) fixed bed fume denitration device for horizontal waste heat boiler

A waste heat boiler and fixed bed technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effects of small overall layout impact, low reaction temperature, and low renovation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

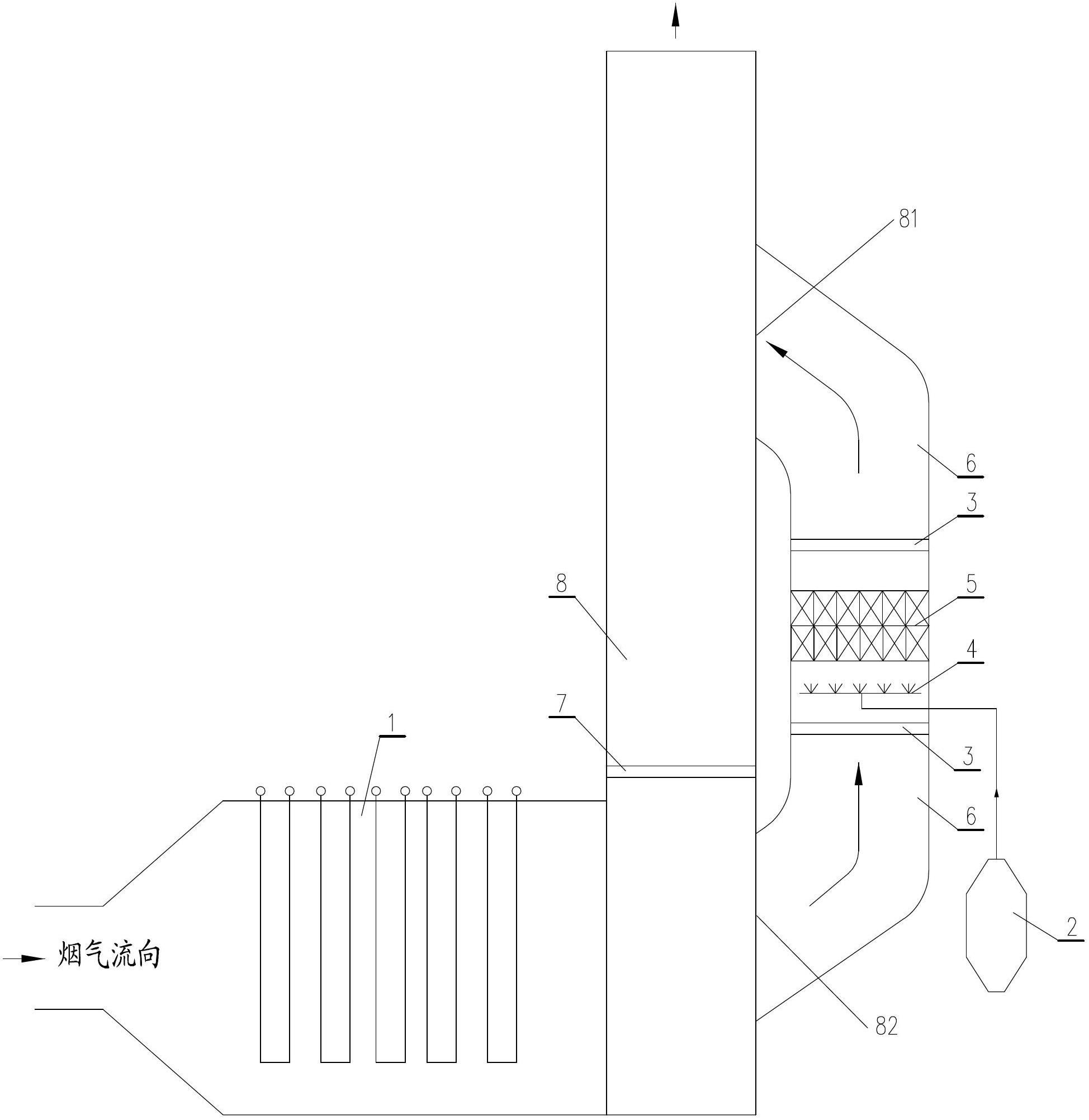

[0032] See Figure 1A , 1B As shown in , it is a structural schematic diagram of a low-temperature SCR fixed-bed flue gas denitrification device modified from an existing horizontal waste heat boiler.

[0033] The device comprises a waste heat boiler 1, the waste heat boiler 1 is connected to a chimney 8, and a connecting flue 6 is arranged on the outside of the chimney 8, and the chimney 8 has an upper inlet 81 and a lower outlet 82, and the connecting flue 6 is connected to the upper inlet 81 and the lower outlet 82. It is connected through; it is also provided with an ammonia / air mixer 2, an ammonia injection mixing device 4 and a low-temperature SCR reactor 5. The ammonia injection mixing device 4 generally includes an ammonia injection grid and a static mixing grid or a vortex mixer. The air mixer 2 is located outside the connecting flue 6, the ammonia injection mixing device 4 and the low-temperature SCR reactor 5 are located inside the connecting flue 6; the ammonia / air...

Embodiment example 2

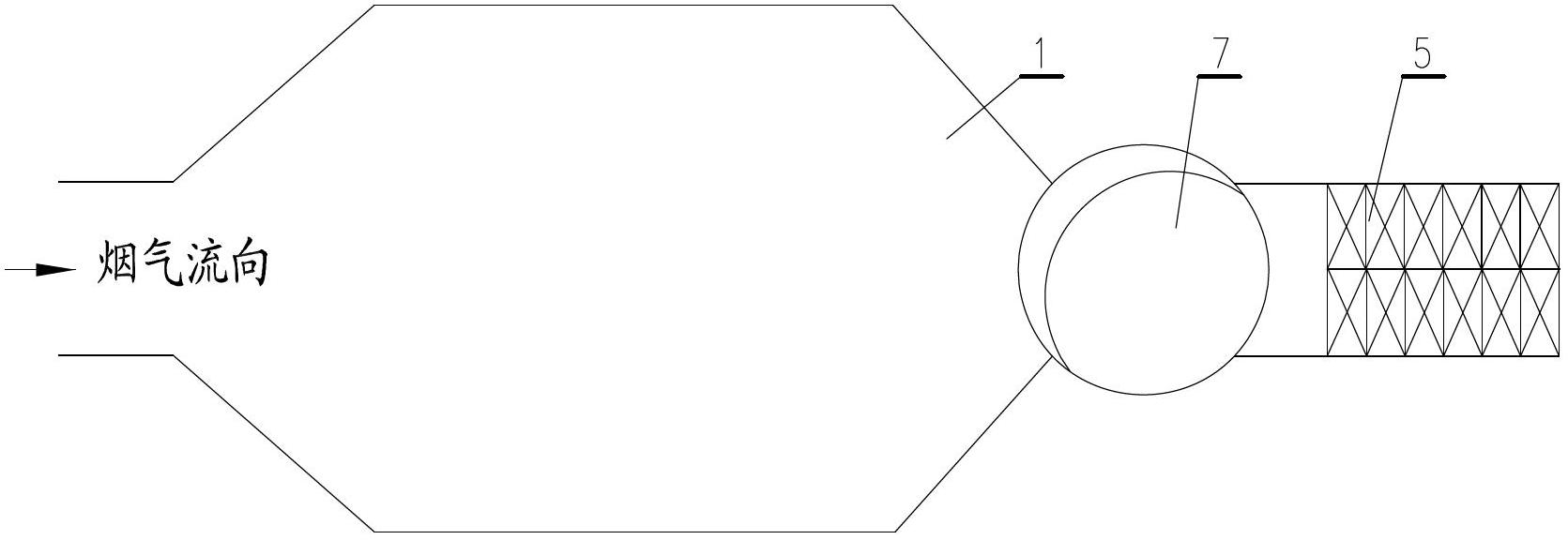

[0038] See Figure 2A , 2B As shown in , it is a structural schematic diagram of a low-temperature SCR fixed-bed flue gas denitrification device modified from an existing horizontal waste heat boiler.

[0039] The device comprises a waste heat boiler 1, the waste heat boiler 1 is connected to a chimney 8, and a connecting flue 6 is arranged on the outside of the chimney 8, and the chimney 8 has an upper inlet 81 and a lower outlet 82, and the connecting flue 6 is connected to the upper inlet 81 and the lower outlet 82. Connected through; also provided with ammonia / air mixer 2, injection-ammonia mixing device 4 and low-temperature SCR reactor 5, the ammonia / air mixer 2 is located outside the connecting flue 6, the ammonia injection mixing device 4 and low-temperature SCR The reactor 5 is arranged inside the connecting flue 6; the ammonia / air mixer 2 is connected to the ammonia injection mixing device 4, and the ammonia injection mixing device 4 is arranged below the low-temper...

Embodiment example 3

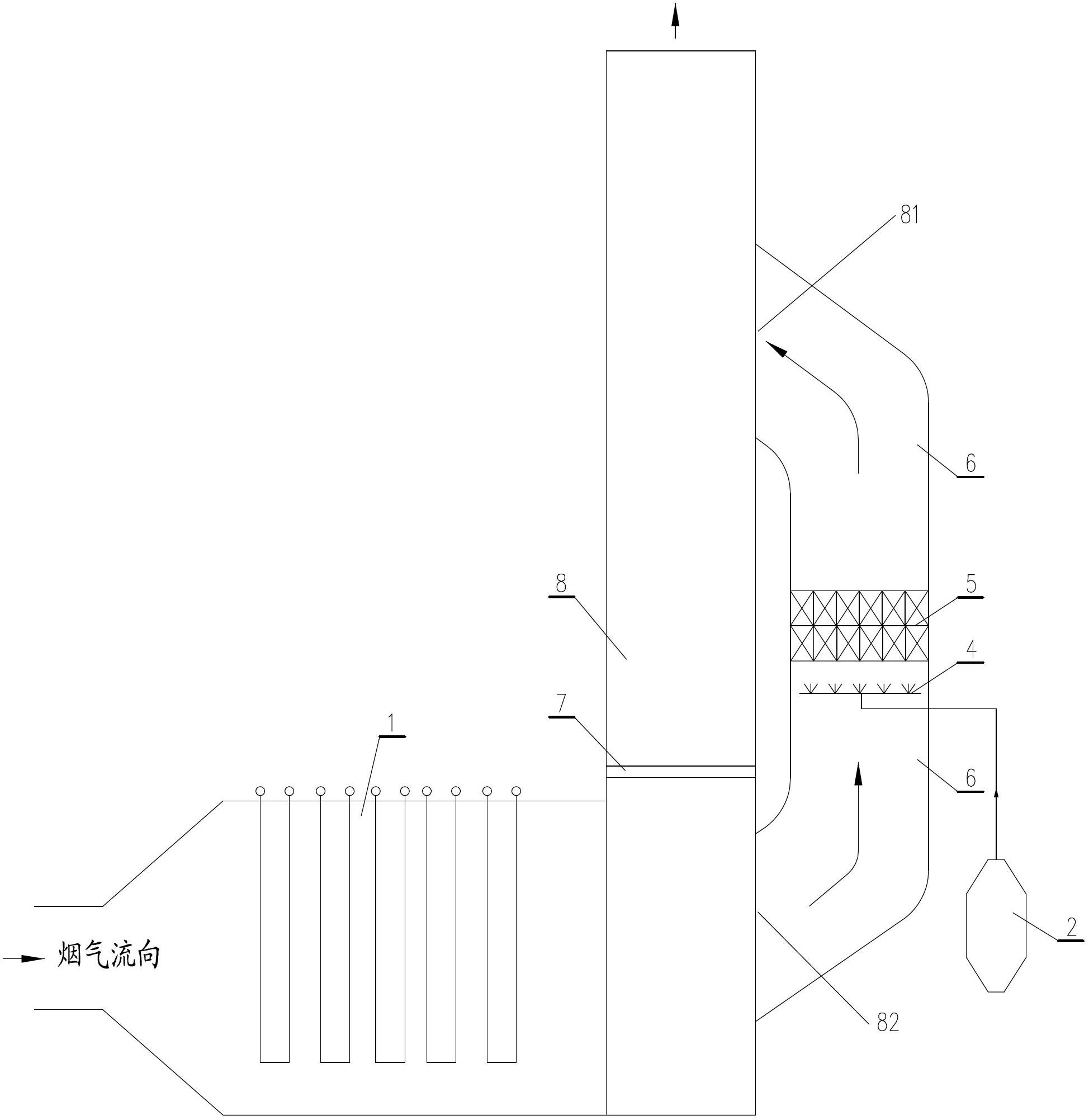

[0043] See Figure 3A , 3B As shown in , it is a structural schematic diagram of a low-temperature SCR fixed-bed flue gas denitrification device modified from an existing horizontal waste heat boiler.

[0044] The device comprises a waste heat boiler 1, the waste heat boiler 1 is connected to a chimney 8, and a connecting flue 6 is arranged on the outside of the chimney 8, and the chimney 8 has an upper inlet 81 and a lower outlet 82, and the connecting flue 6 is connected to the upper inlet 81 and the lower outlet 82. Connected through; also provided with ammonia / air mixer 2, ammonia injection mixing device 4 and low-temperature SCR reactor 5, the ammonia / air mixer 2 is located outside the connecting flue 6, the ammonia injection mixing device 4 and low-temperature SCR reaction The device 5 is arranged inside the connecting flue 6; the ammonia / air mixer 2 is connected to the ammonia injection mixing device 4, and the ammonia injection mixing device 4 is arranged below the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com