Novel polymer-based composite material and preparation method of composite material as well as method for deep fluorine removal of water body

A technology of composite materials and polymers, applied in the fields of alkali metal compounds, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of low fluoride ion adsorption capacity and low fluoride removal efficiency, so as to improve adsorption capacity and selectivity performance, reducing the concentration of fluoride ions, and enhancing the selectivity of fluoride removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The method for the depth of water body defluoridation of the present embodiment 1 comprises the following steps:

[0042] (a) Prepare simulated fluoride-containing wastewater with a fluoride concentration of 5 mg / L, SO 4 2- , Cl - , NO 3 - The contents are 50 mg / L, 30 mg / L, and 8 mg / L respectively. After filtering, adjust the pH of the raw water to 5.5;

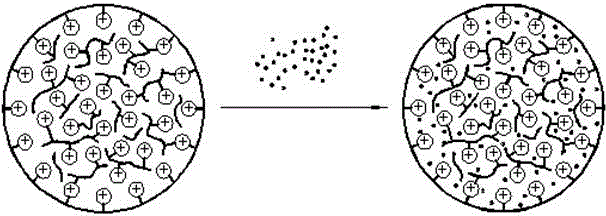

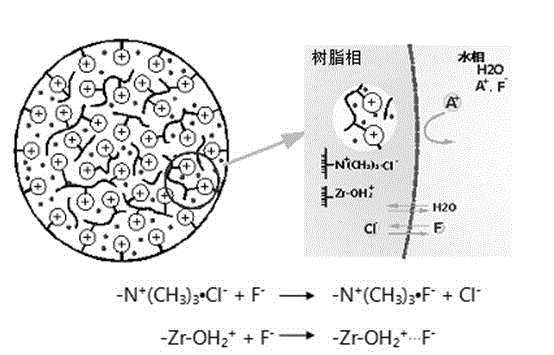

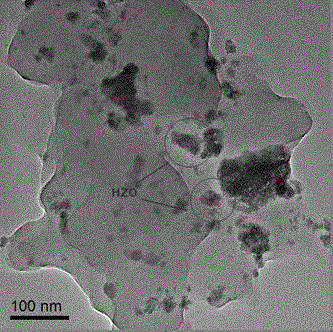

[0043] (b) The simulated adsorption tower device is filled with polymer-based composite materials, and the simulated fluorine-containing wastewater passes through the adsorption tower at a temperature of 7±2°C with a flow rate of 2 BV / h. combine figure 1 , figure 2 , the polymer-based composite material used in this step (b), the matrix is styrene-divinylbenzene copolymer spheres, the particle size distribution is between 0.5-0.8 mm, the pore size distribution is between 5-50 nm, and contains Rich nanopore structure and positively charged functional groups can pre-concentrate negatively charged fluoride ions...

Embodiment 2

[0052] The method for the depth of water body defluoridation of present embodiment 2 comprises the following steps:

[0053] (a) Prepare simulated fluorine-containing wastewater with a fluorine concentration of 10 mg / L, SO 4 2- , Cl - , NO 3 - The contents are 50 mg / L, 30 mg / L, and 8 mg / L respectively. After filtering, adjust the pH of the raw water to 3.0;

[0054] (b) A simulated adsorption tower device, the tower is filled with polymer-based composite materials, and the simulated fluorine-containing wastewater passes through the adsorption tower at a temperature of 25±5°C with a flow rate of 6 BV / h; the used in step (b) Polymer-based composite material, the matrix is styrene-divinylbenzene copolymer spheres, the particle size distribution is between 0.8-1.0 mm, and the pore size distribution is between 40-80 nm. The polymer contains rich nanopore structure and positive charge Sexual functional groups can pre-enrich negatively charged fluoride ions. Hydrated zirconia...

Embodiment 3

[0063] The method for the depth of water body defluoridation of present embodiment 3 comprises the following steps:

[0064] (a) Prepare simulated fluorine-containing wastewater with a fluoride concentration of 2 mg / L, SO 4 2- , Cl - , NO 3 - The contents are 50 mg / L, 30 mg / L, and 8 mg / L respectively. After filtering, adjust the pH of the raw water to 3.5;

[0065] (b) A simulated adsorption tower device, the tower is filled with polymer-based composite materials, and the simulated fluorine-containing wastewater passes through the adsorption tower at a temperature of 35±5°C with a flow rate of 10 BV / h; the used in step (b) Polymer-based composite materials, the matrix of which is styrene-divinylbenzene copolymer spheres, the particle size distribution is between 1.0-1.5 mm, and the pore size distribution is between 60-100 nm. The polymer contains rich nanopore structure and positive charge Sexual functional groups can pre-enrich negatively charged fluoride ions. Hydrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com