Integrated up-flow reactor and advanced treatment method of fermentation industrial effluent

A reactor and flow-type technology, which is applied in the integrated upflow reactor and the field of advanced treatment of fermentation industrial wastewater, can solve the problems of long start-up time and short residence time, and achieve the effect of improving biodegradability and easy degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

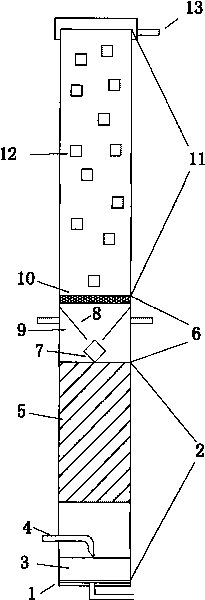

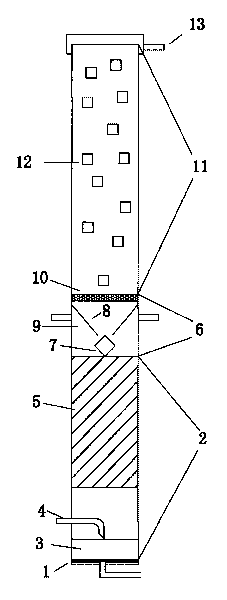

[0027] In the integrated upflow reactor, the wastewater enters the upflow anaerobic biofilter 2 of the reactor from the bottom water distribution device 1. It is in an upflow state, and first passes through the sludge bed 3, and the biological sludge conducts preliminary purification of refractory organic matter in the wastewater. Hydrolysis, acidification, and interception of suspended particulate matter, and then flow up through the packing layer 5, under the action of a large number of anaerobic microorganisms attached to the packing, the refractory organic matter is further degraded into organic matter that is easy to aerobic biodegradation; then the water flow rises through the transition zone At 6 o'clock, the anaerobic biological sludge rising with the water flow is blocked by the diamond-shaped baffle 7 and the inclined plate 8 and cannot enter the upper moving bed biofilm reactor 11, most of it settles to the sludge bed 2 at the bottom of the reactor, and a small part i...

Embodiment 2

[0039] The integrated upflow reactor with the same structure as in Example 1 was used to process the anaerobic and aerobic biochemical treatment effluent of another vitamin C pharmaceutical factory. The treatment capacity was 3000t / d, and its water quality was specifically shown in Table 3:

[0040] Table 3 Anaerobic plus aerobic biochemical treatment effluent of a vitamin C pharmaceutical factory

[0041] COD Cr (mg / L)

[0042] The parameters of the integrated upflow reactor are as follows: the cross section of the whole reactor is square, the side length is 5m, the height of the moving bed biofilm reactor is 10m, the height of the upflow anaerobic biofilter is 6m, and the height of the transition zone is 2m. The total volume is 450m 3 , The total hydraulic retention time is 3.6h. The filler used in the upflow anaerobic biological filter is biological rope, which is basically filled; the suspended filler used in the moving bed biofilm reactor has a specific gravi...

Embodiment 3

[0048] The anaerobic biochemical treatment effluent of citric acid production wastewater is processed with the integrated upflow reactor with the structure of Example 1, and the treatment capacity is 1500t / d, and its water quality situation is specifically shown in Table 5:

[0049] Table 5 The effluent quality of anaerobic and aerobic biochemical treatment of production wastewater from a citric acid factory

[0050] COD Cr (mg / L)

BOD(mg / L)

Chroma (dilution factor)

Salinity (mg / L)

pH

400

90

130

4900

7.1

[0051] The parameters of the integrated upflow reactor are as follows: the cross section of the whole reactor is square, the side length is 2.5m, the height of the moving bed biofilm reactor is 5m, the height of the upflow anaerobic biofilter is 3m, and the height of the transition zone is 1m , with a total volume of 225m 3 , The total hydraulic retention time is 3.6h. The filler used in the upflow anaerobic biol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com