Preparation method of copper-containing antibacterial fibre

An antibacterial fiber and antibacterial powder technology is applied in the field of preparation of copper-containing antibacterial fibers, which can solve the problems of poor persistence of antibacterial effect, poor antibacterial effect of antibacterial fibers, and high processing cost of antibacterial fibers, achieve excellent antibacterial performance, avoid long-term accumulation, and achieve excellent antibacterial properties. bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

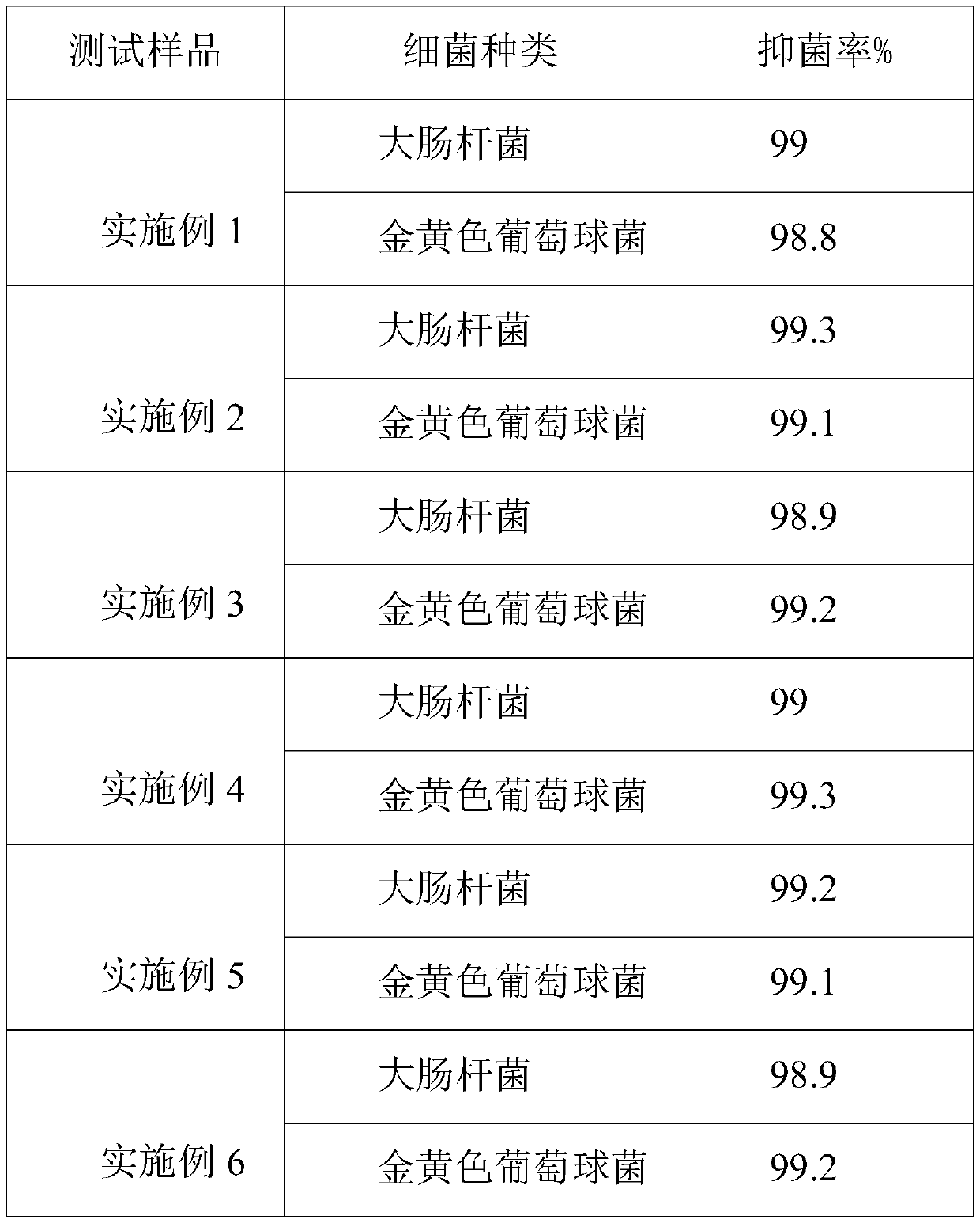

Examples

preparation example Construction

[0018] The preparation method of copper-containing antibacterial fiber of the present invention is implemented according to the following steps:

[0019] Step 1: Prepare antibacterial powder,

[0020] 1.1) Prepare Ti-30Cu antibacterial powder. Select titanium powder of 300-600 mesh and copper powder of 300-800 mesh, the mass ratio of titanium powder and copper powder is 70:30, weigh the raw material powder according to the ratio, and mix the raw material powder on a ball mill; Molded into a green embryo under a pressure of ~500Mpa, and the vacuum degree is lower than 1×10 -3 Under Mpa environment, heat the prefabricated green body to 700-1100°C for high-temperature sintering, the sintering time is 1-4h, the mechanical pressure is 5-25Mpa, and the metallurgical powder Ti-30Cu antibacterial powder is obtained after cooling with the furnace, in which the copper phase After treatment, it appears as ε-Cu phase; then the Ti-30Cu antibacterial powder is ball milled on a planetary h...

Embodiment 1

[0027] Step 1: Prepare Ti-30Cu antibacterial powder,

[0028] Select 500-mesh titanium powder and 600-mesh copper powder, the mass ratio of titanium powder and copper powder is 70:30; weigh the raw material powder according to the ratio, and ball mill the raw material powder on a ball mill to mix evenly. Then it is molded into a green embryo under a pressure of 350Mpa, and the vacuum degree is lower than 1×10 -3 Under the environment of MPa, the prefabricated green body is heated to 800°C for high-temperature sintering, the sintering time is 3h, and the mechanical pressure is 20Mpa. After cooling with the furnace, Ti-30Cu antibacterial powder is obtained, and the copper phase is treated as ε-Cu. Mutually. Then, the Ti-30Cu antibacterial powder is ball-milled on a planetary high-energy ball mill for 48 hours to obtain an ultrafine Ti-30Cu antibacterial powder with a particle size of less than 0.5 μm.

[0029] Step 2: Preparation of antimicrobial fiber melt

[0030] With the ...

Embodiment 2

[0034] Step 1: Preparation of Ti-30Cu antibacterial powder

[0035] Weigh 400-mesh titanium powder and 500-mesh copper powder, the mass ratio of titanium powder and copper powder is 70:30, weigh the raw material powder according to this ratio, and ball mill the raw material powder on a ball mill to mix evenly. Then it is molded into a green embryo under a pressure of 450Mpa, and the vacuum degree is lower than 1×10 -3 Under the environment of Mpa, the prefabricated green body is heated to 900°C for high-temperature sintering, the sintering time is 1.5h, and the mechanical pressure is 15Mpa. After cooling with the furnace, Ti-30Cu antibacterial powder is obtained, and the copper phase appears as ε- Cu phase. Then, the Ti-30Cu antibacterial powder was ball-milled on a planetary high-energy ball mill for 46 hours to obtain an ultrafine Ti-30Cu antibacterial powder with a particle size of less than 0.45 μm.

[0036] Step 2: Preparation of antimicrobial fiber melt

[0037]With t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com