Photocatalyst and preparation method and application thereof

A photocatalyst and cuboid technology, applied in the field of photocatalysis, can solve problems such as low efficiency and easy deactivation, and achieve the effects of cost saving, strong redox ability, and good activity stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation steps of the present invention are as follows:

[0019] The equimolar amount of raw material CdCl 2 ·2.5H 2 O and Na 2 SnO 3 ·4H 2 Put O into the beaker, add 60 ml of distilled water to the beaker, stir vigorously for 30 min at room temperature to form a uniform white suspension, then adjust the pH of the above turbid liquid to 11 with 5% ammonia water, and combine the turbid liquid It was transferred to a 100 ml microwave reactor and reacted for 2 h at 160°C in a microwave digester. After cooling, the product was centrifuged and washed, and the product was dried in an oven at 60°C to obtain the photocatalyst.

Embodiment 1

[0021] CdSnO with nano hollow cuboid morphology 3 ·3H 2 Preparation of O photocatalyst

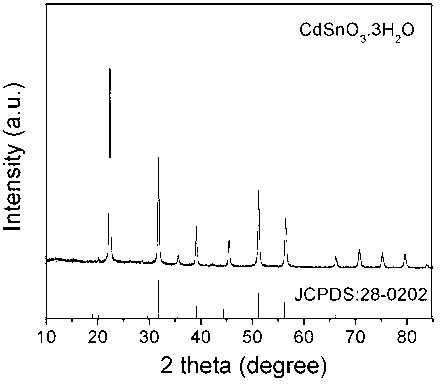

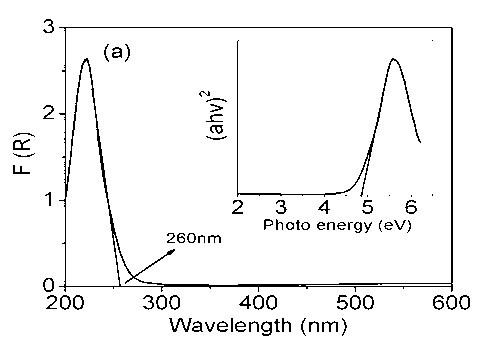

[0022] The equimolar amount of raw material CdCl 2 ·2.5H 2 O and Na 2 SnO 3 ·4H 2 Put O into the beaker, add 60 ml of distilled water to the beaker, stir vigorously for 30 min at room temperature to form a uniform white suspension, then adjust the pH of the above turbid liquid to 11 with 5% ammonia water, and combine the turbid liquid It was transferred to a 100 ml microwave reactor and reacted for 2 h at 160°C in a microwave digester. After cooling, the product was centrifuged and washed, and the product was dried in an oven at 60°C to obtain the photocatalyst. figure 1 Demonstrates the CdSnO of the present invention 3 ·3H 2 The X-ray diffraction (XRD) pattern of the O photocatalyst, from which you can find the prepared CdSnO 3 ·3H 2 O is the pure phase. figure 2 Demonstrates the CdSnO of the present invention 3 ·3H 2 The UV-visible diffuse reflectance image of O photocatalyst, from which you...

Embodiment 2

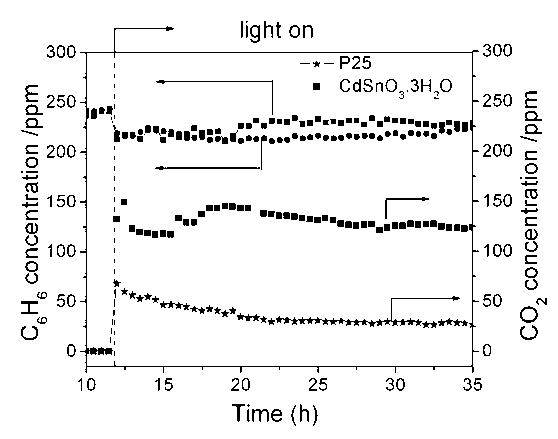

[0024] CdSnO with nano hollow cuboid morphology 3 ·3H 2 O photocatalyst gas phase degradation of benzene

[0025] The prepared catalyst was used to degrade gas phase benzene to evaluate its photocatalytic performance. The reaction device consists of a quartz glass tube (length 11 cm, diameter 2.4 mm), the amount of catalyst is 0.3 g, sieved 50-70 mesh, the catalyst is filled in the quartz tube, and the two ends of the catalyst are respectively plugged with quartz wool. The K-type thermocouple extends into the catalyst reaction tube to detect the temperature of the system, and uses an electric fan to cool the system so that the temperature of the system is always maintained at room temperature. The airflow rate is 20 mL / min. The light source uses 4 4 W UV lamps. , The main excitation wavelength is 254 nm. The reactants and products are automatically sampled by online chromatography (HP6890, Porapak R packed column, TCD, FID) at regular intervals, and the concentration of the simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com