LED chip silicone die bond adhesive

An LED chip, silicone technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of yellowing, poor high-temperature adhesion of silicone solid-state adhesives, and incomplete cross-linking, etc. Improve high temperature hardness and strength, enhance high temperature adhesion of resin, and enhance the effect of skeleton structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

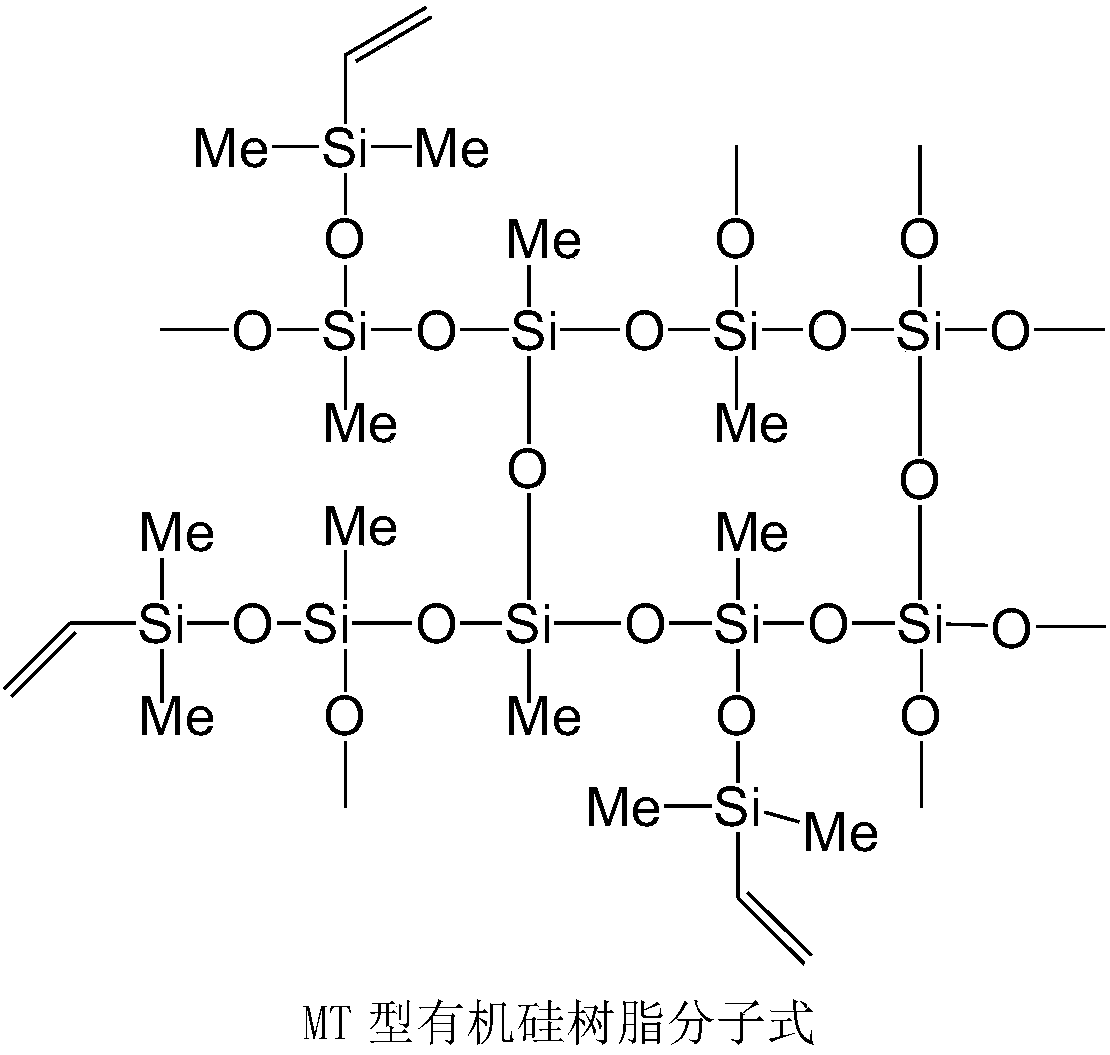

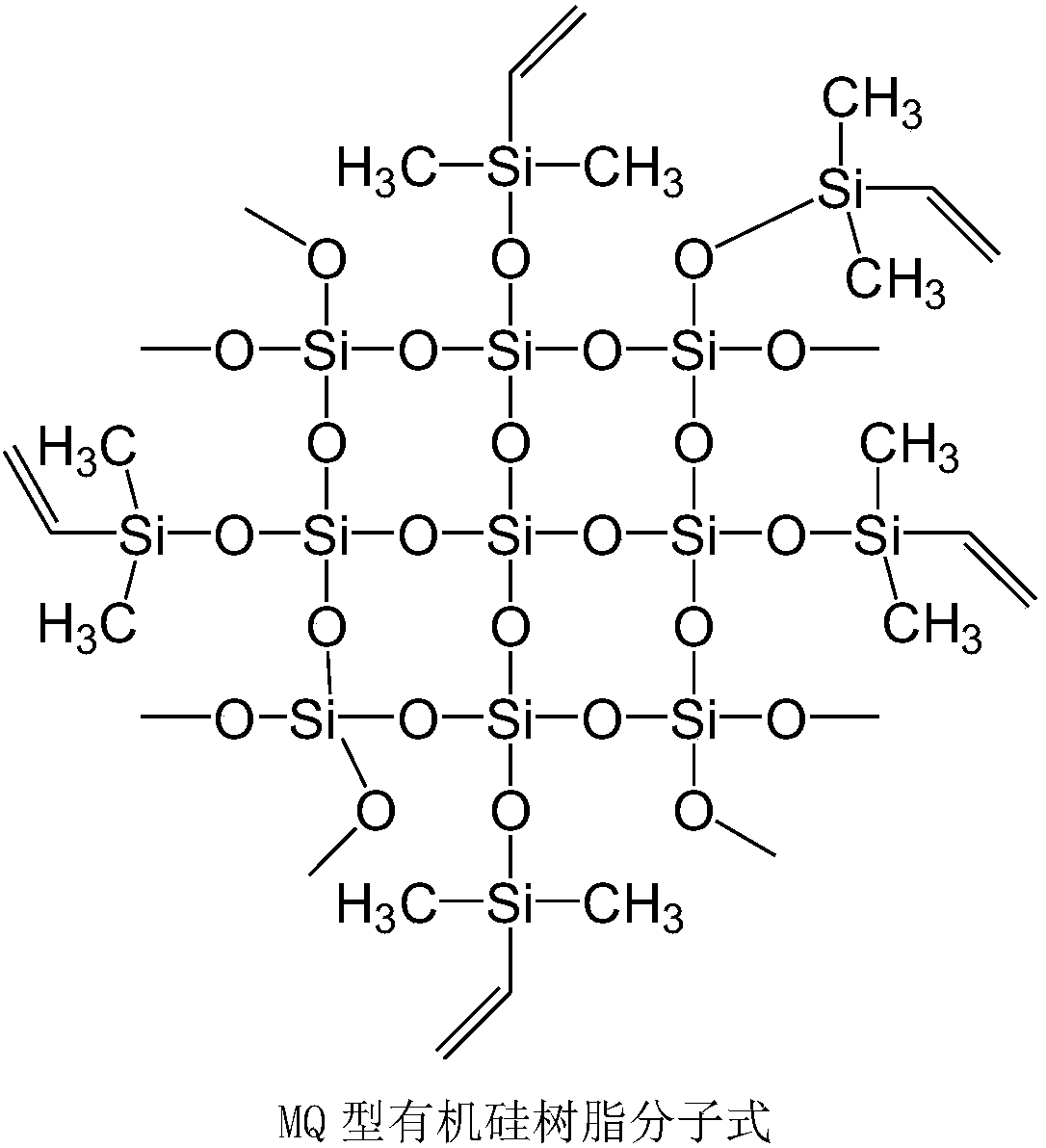

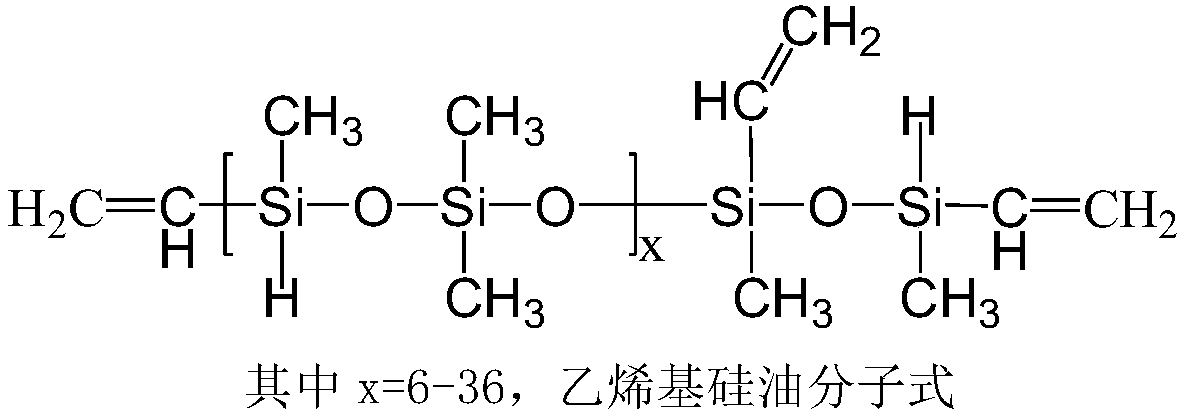

[0027] The preparation steps of the silicone crystal-bonding glue are as follows: 30 parts of MT type silicone resin (molecular weight is 3000), 50 parts of MQ type silicone resin (molecular weight is 5000) and 5 parts of crosslinking agent (wherein x=18) in Pre-mix at 80°C, then add 0.1 part of catalyst, pre-mix again at 80°C, after mixing, cool to room temperature, add 5 parts of special filler, 0.3 parts of inhibitor dibutyl maleate, silicone oil (wherein n=10) 15 parts, adhesive (molecular weight: 1500) 2 parts, stir and mix slowly at room temperature, after mixing evenly, the silicone crystal-bonding glue is obtained.

Embodiment 2

[0029] The preparation steps of the silicone crystal-bonding glue are as follows: 50 parts of MT type silicone resin (molecular weight is 3000), 30 parts of MQ type silicone resin (molecular weight is 5000) and 5 parts of crosslinking agent (wherein x=18) in Pre-mix at 80°C, then add 0.1 part of catalyst, pre-mix again at 80°C, after mixing, cool to room temperature, add 5 parts of special filler, 0.3 parts of inhibitor dibutyl maleate, silicone oil (wherein n=10) 15 parts, adhesive (molecular weight: 1500) 2 parts, stir and mix slowly at room temperature, after mixing evenly, the silicone crystal-bonding glue is obtained.

Embodiment 3

[0031] The preparation steps of the silicone crystal-bonding glue are as follows: 40 parts of MT type silicone resin (molecular weight is 3000), 40 parts of MQ type silicone resin (molecular weight is 5000) and 5 parts of crosslinking agent (wherein x=18) in Pre-mix at 80°C, then add 0.1 part of catalyst, pre-mix again at 80°C, after mixing, cool to room temperature, add 5 parts of special filler, 0.3 parts of inhibitor dibutyl maleate, silicone oil (wherein n=10) 15 parts, adhesive (molecular weight: 1500) 2 parts, stir and mix slowly at room temperature, after mixing evenly, the silicone crystal-bonding glue is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com