High-wear-resistance and high-strength polyurethane court material, and preparation method and using method thereof

A high-strength, polyurethane technology, applied in the field of polyurethane, can solve the problems of poor infiltration of basic materials, fast reaction speed, poor elasticity, etc., to achieve the effect of improving tensile strength, good long-term usability, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

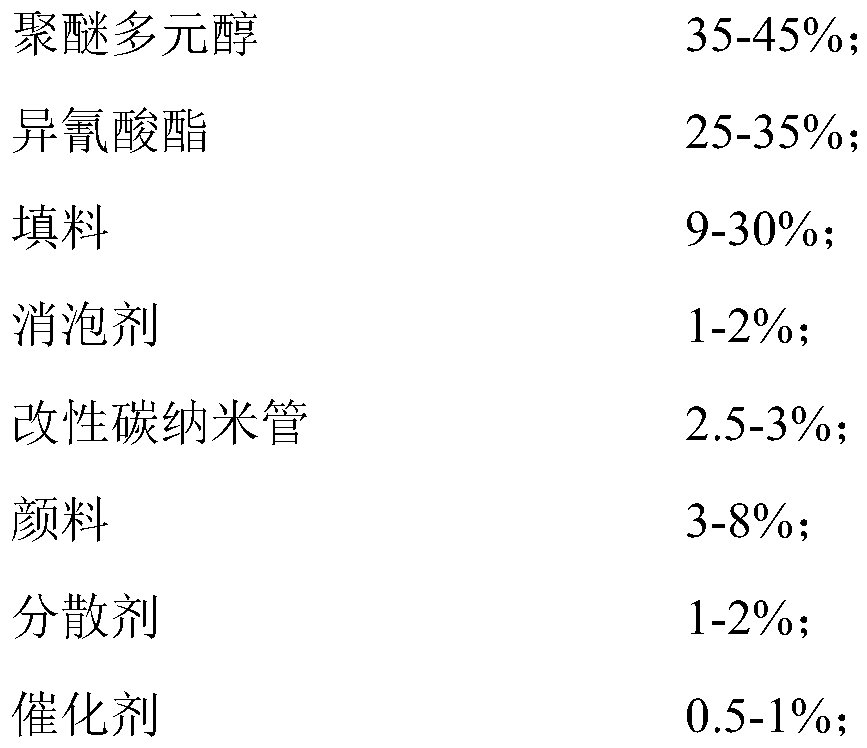

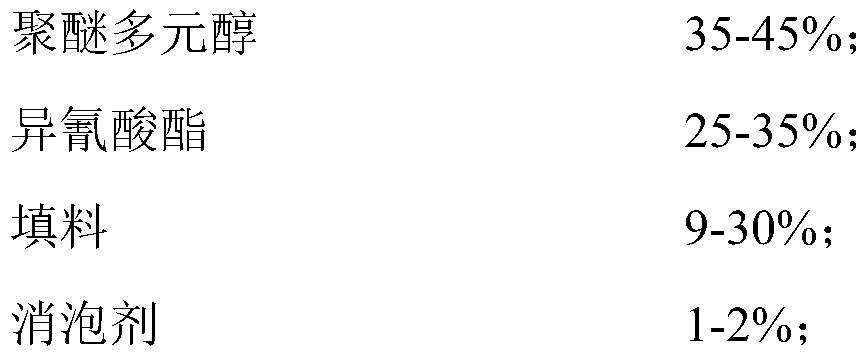

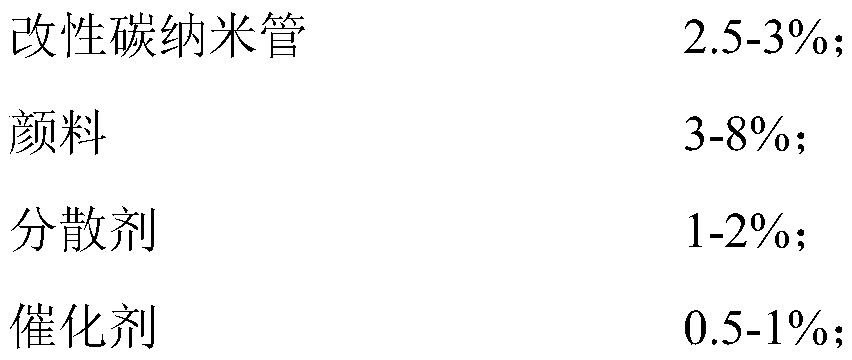

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of modified carbon nanotubes: place carbon nanotubes in concentrated nitric acid, soak them at 30°C for 6 hours, take them out and wash them until they are neutral; then place them in silane coupling agent KH-560, and stir them at 60°C 2h, washing and drying to obtain modified carbon nanotubes.

[0035] (2) Preparation of component B of polyurethane court material: Put 35kg polyether polyol VOANOL CP-6001, 14kg325 mesh talcum powder, 8kg iron oxide green 5605 and 2kg dispersant YCK-2330 into the reaction kettle and mix at 800r / min Stir for 13 minutes, add 35kg44C, continue to stir at 800r / min, react at 75°C for 3h, take a sample to detect that the NCO content is 10.29, then cool down to 65°C, then add 3kg of modified carbon nanotubes, and turn at 800r / min Stir at a rotating speed for 18 minutes, and finally add 1kg organic bismuth catalyst Kat22 and 2kg defoamer RJ-4040, and stir at a rotating speed of 1800r / min for 25 minutes to obtain component B of th...

Embodiment 2

[0039] (1) Preparation of modified carbon nanotubes: place carbon nanotubes in concentrated nitric acid, soak them at 30°C for 6 hours, take them out and wash them until they are neutral; then place them in silane coupling agent KH-560, and stir them at 60°C 2h, washing and drying to obtain modified carbon nanotubes.

[0040](2) Preparation of component B of polyurethane court material: Put 37kg of polyether polyol VOANOL 3010, 30kg of 600-mesh talcum powder, 3kg of phthalocyanine green 5605 and 1kg of dispersant YCK-2330 into the reactor and mix them, and stir at 800r / min for 15min. Add 25kg of 44C, continue stirring at 800r / min, react at 80°C for 2 hours, take a sample to detect that the NCO content is 7.623, then cool down to 70°C, then add 2.5kg of modified carbon nanotubes, and stir at 800r / min After 20 minutes, finally add 0.5kg organic bismuth catalyst Kat22 and 1kg defoamer RJ-4040, and stir at 1800r / min for 20 minutes to obtain component B of carbon nanotube modified ...

Embodiment 3

[0044] (1) Preparation of modified carbon nanotubes: place carbon nanotubes in concentrated nitric acid, soak them at 30°C for 6 hours, take them out and wash them until they are neutral; then place them in silane coupling agent KH-560, and stir them at 60°C 2h, washing and drying to obtain modified carbon nanotubes.

[0045] (2) Preparation of component B of polyurethane court material: Put 45kg of polyether polyol VOANOL NF-927, 9kg of 1000 mesh talcum powder, 6.5kg of iron oxide red 5605 and 1.5kg of dispersant YCK-2330 into the reactor and mix them at 800r / Stir at min speed for 18 min, add 33kg44C, continue to stir at 800r / min speed, react at 78°C for 2.5h, take a sample to detect that the NCO content is 10.143, then cool down to 68°C, then add 2.7kg of modified carbon nanotubes, Stir at 800r / min for 25min, finally add 0.8kg organic bismuth catalyst Kat22, 1.5kg defoamer RJ-4040, and stir at 1800r / min for 18min to obtain component B of carbon nanotube modified polyurethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com