Preparation method of manganese-doped sodium-ion battery positive electrode material

A technology for sodium ion batteries and positive electrode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of doping technology, less research on doping element doping, difficult process methods and parameter control, and process control. Stability requirements are extremely high and other issues, to achieve the effect of improving specific capacity, side reactions between barrier material interface and electrolyte, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

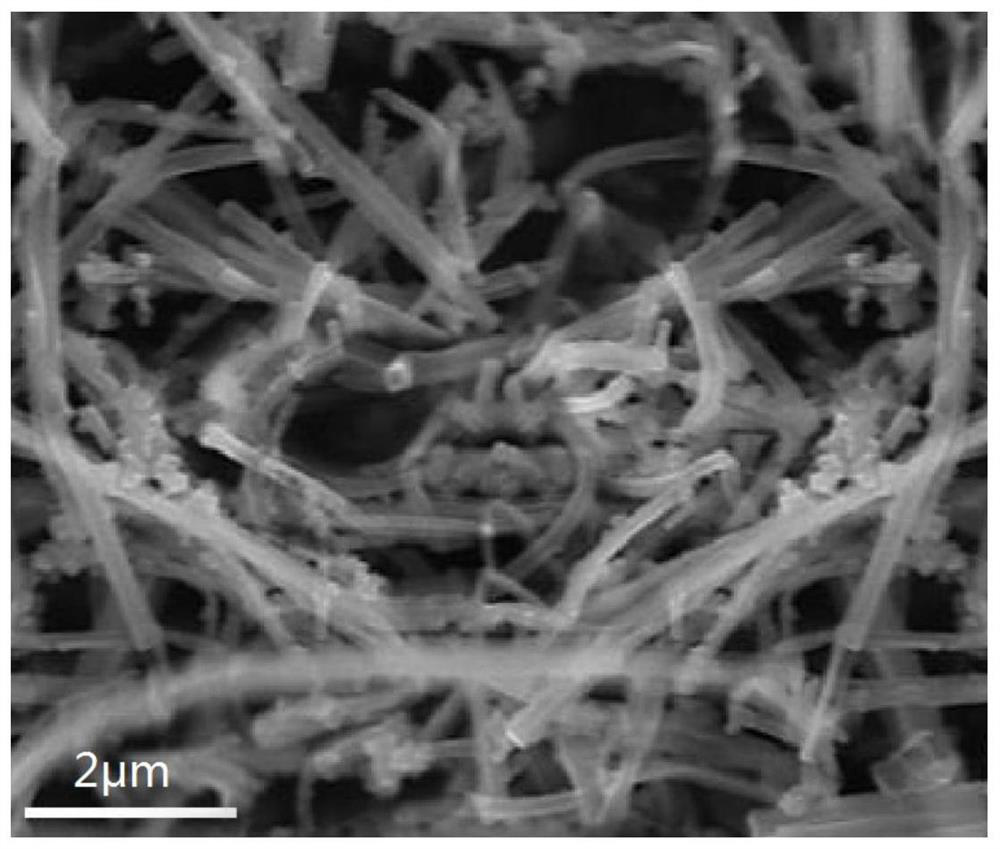

Image

Examples

Embodiment 1

[0032] In this embodiment, a positive material for doping manganese sodium ion battery is prepared, and the specific process is:

[0033] (1) After dissolving the trioxide with hydrochloric acid, manganese chloride is added, formulated into a mixed metal salt solution having a total metal ion concentration of 0.1 mol / L, wherein the molar ratio of ruthenium and manganese is 5:95;

[0034] (2) The sodium hydroxide and a concentration of sodium hydroxide and a concentration of sodium hydroxide and a concentration of 0.3 mol / L were prepared, that is, an alkaline oxidant solution.

[0035] (3) The mixed metal salt solution is added dropwise to the alkaline oxidant solution, and the control reaction system temperature is 2-10 ° C, and the pH ≥ 10.5 of the basic oxidant solution is always ensured, the oxidant is always sufficient, and the reaction is completed. Solid-liquid separation is carried out to obtain solid materials;

[0036] (4) After the solid material is dried, the amount...

Embodiment 2

[0039] In this embodiment, a positive material for doping manganese sodium ion battery is prepared, and the specific process is:

[0040] (1) After dissolving the trioxide, a chloride solution was added to a mixed metal salt solution having a total concentration of 0.2 mol / L of a metal ion, wherein the molar ratio of bismuth and manganese was 5:95;

[0041] (2) The mixture of sodium hydroxide and sodium hydroxide having a concentration of 2.0 mol / L is formulated, that is, a basic oxidant solution;

[0042] (3) The mixed metal salt solution is added dropwise to the alkaline oxidant solution, and the control reaction system temperature is 2-10 ° C, and the pH ≥ 10.5 of the basic oxidant solution is always ensured, the oxidant is always sufficient, and the reaction is completed. Solid-liquid separation is carried out to obtain solid materials;

[0043] (4) After drying, the solid material is dried in low temperature, the ratio of the substance of the sodium atom and the manganese...

Embodiment 3

[0046] In this embodiment, a positive material for doping manganese sodium ion battery is prepared, and the specific process is:

[0047](1) After dissolving the trioxide and trioxide with hydrochloric acid, manganese chloride is added, formulated into a mixed metal salt solution having a total metal ion concentration of 0.3 mol / L, wherein the molar ratio of antimony, bismuth and manganese is 5: 5: 90;

[0048] (2) A mixed solution of sodium hydroxide and sodium hydroxide having a concentration of 4.0 mol / L is a concentration of sodium hypochlorite, which is an alkaline oxidant solution.

[0049] (3) The mixed metal salt solution is added dropwise to the alkaline oxidant solution, and the temperature of the reaction system is 2-10 ° C and always ensures that the basic oxidant solution pH ≥ 10.5, the oxidant is always sufficient, and the reaction is completed Solid-liquid separation to obtain solid materials;

[0050] (4) After drying, the solid material is dried in low tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com