Organic modified nanoporous silica aerogel and preparation method thereof

A silicon dioxide and nanopore technology, applied in the directions of silicon dioxide, silicon oxide, etc., can solve the problems of complicated preparation process, long time consumption, increase preparation cost, etc., and achieve good mechanical properties, reduced preparation cost, and low-cost preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

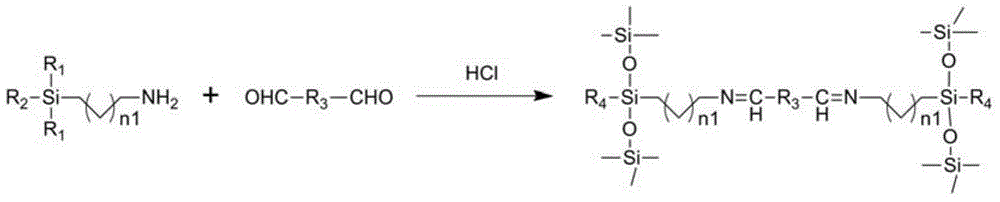

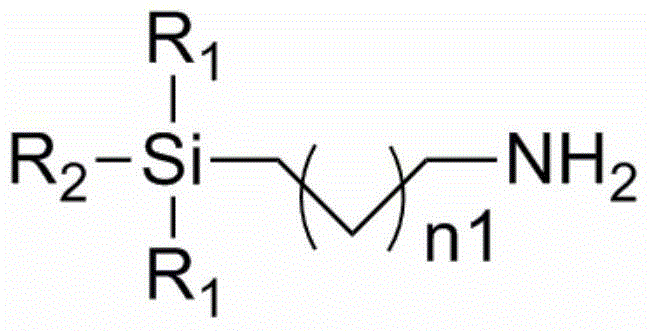

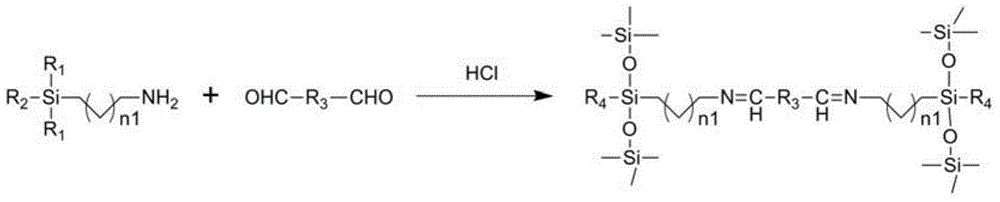

Method used

Image

Examples

Embodiment example 1

[0032] Mix 3-aminopropyltrimethoxysilane, terephthalaldehyde, 0.2M hydrochloric acid solution and absolute ethanol at a molar ratio of 1:0.33:20:0.4, stir at room temperature for 20min to mix evenly, and seal the above solution Store and incubate at 40°C for 12h to form a gel. Then, the excess ethanol / water mixture was removed from the obtained gel, soaked in an appropriate amount of absolute ethanol, and kept at 40° C. for 24 hours to remove residual chemical substances. Repeat this 2 times. Then the temperature was raised to 80°C (1°C / min), and dried under normal pressure for 36h to obtain the organic composite modified nanoporous SiO 2 airgel.

Embodiment example 2

[0034] Mix 3-aminopropyldimethylethoxysilane, terephthalaldehyde, 0.4M hydrochloric acid and absolute ethanol in a molar ratio of 1:1:15:0.4, stir at room temperature for 20min and mix evenly, and the above solution Store in an airtight container and incubate at 40°C for 12 hours to form a gel. Then, the excess ethanol / water mixture was removed from the obtained gel, soaked in an appropriate amount of absolute ethanol, and kept at 40° C. for 24 hours to remove residual chemical substances. Repeat this 2 times. Then the temperature was raised to 60°C (2.5°C / min), and dried under normal pressure for 36 hours to obtain organic composite modified nanoporous SiO2 airgel.

Embodiment example 3

[0036] 3-aminopropyltrimethoxysilane, 4,4 ’ - Mix biphenyldiformaldehyde, 0.4M hydrochloric acid solution and absolute ethanol at a molar ratio of 1:0.8:17:0.5, stir at room temperature for 20 minutes to mix evenly, seal and store the above solution, and keep it at 40°C for 12 hours to form a gel . Then, the excess ethanol / water mixture was removed from the obtained gel, soaked in an appropriate amount of absolute ethanol, and kept at 40° C. for 24 hours to remove residual chemical substances. Repeat this 2 times. Then the temperature was raised to 120°C (5°C / min), and dried under normal pressure for 36h to obtain the organic composite modified nanoporous SiO 2 airgel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com