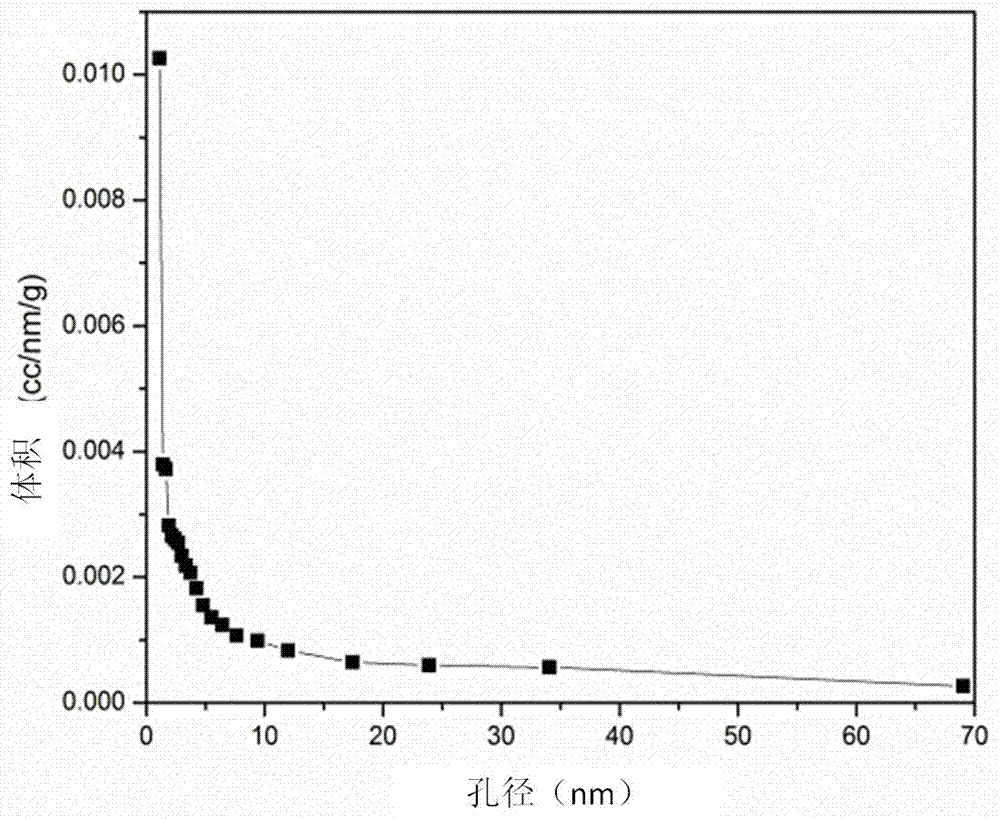

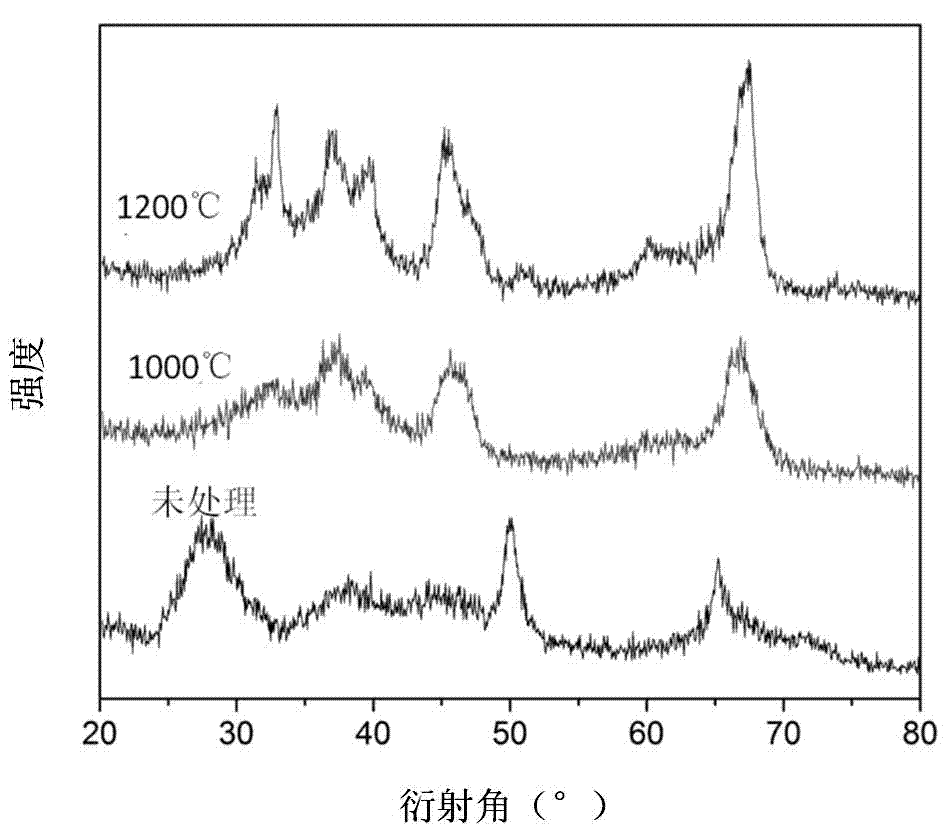

Preparation method of high temperature-resistant alumina aerogel material

A technology of alumina aerogel and alumina sol is applied in the field of preparation of high temperature resistant alumina aerogel materials to achieve the effects of enhancing skeleton structure, improving temperature resistance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Heat up the mixed solution of ethanol and deionized water to 60°C through a heating device, put a certain amount of aluminum sec-butoxide into it, stir at constant temperature for 10 minutes until it is clear, and then cool the sol to room temperature. Take a certain amount of nitric acid and add to the above sol. The obtained sol was mixed with a certain proportion of acetone and aniline solution. After continuing to stir for 10 minutes, the desired wet gel can be obtained. The molar ratio of aluminum sec-butoxide, deionized water, ethanol, nitric acid, acetone and aniline is 1:0.3:3.06:0.01:1.4:1.1. The wet gel was covered with a small amount of alcohol and aged for 1 day, and then replaced with alcohol 3 times for 12 hours each time.

[0027] Put the alumina wet gel into the supercritical drying equipment, take the partially hydrolyzed aluminum salt and tetraethyl orthosilicate mixed solution with a molar ratio of 3:1, put it into the autoclave, pre-fill...

Embodiment 2

[0029] Example 2: The mixed solution of ethanol and deionized water was heated to 70° C. by a heating device, and a certain amount of aluminum sec-butoxide was added thereto, stirred at constant temperature for 10 minutes until it was clarified, and then the sol was cooled to room temperature. A certain amount of hydrochloric acid was added to the above sol. The prepared sol was mixed with a certain proportion of methanol, deionized water, acetone and aniline solution. After continuing to stir for 15 minutes, the desired wet gel can be obtained. The molar ratio of aluminum sec-butoxide, deionized water, ethanol, hydrochloric acid, methanol, acetone and aniline is 1:0.6:10.5:0.039:0.25:0.7:0.5. The wet gel was covered with a small amount of alcohol, aged for 2 days, and then replaced with alcohol twice, each time for 18 hours.

[0030] Put the alumina wet gel into the supercritical drying equipment, take the partially hydrolyzed aluminum salt and tetraethyl orthosilicate mixe...

Embodiment 3

[0032] Example 3: The ethanol solution was heated to 68° C. by a heating device, and a certain amount of aluminum isopropoxide was added thereto, stirred at constant temperature for 8 minutes until it was clear, and then the sol was cooled to room temperature. Take a certain amount of nitric acid and add to the above sol. The obtained sol was mixed with a certain proportion of acetone and aniline solution. After continuing to stir for 15 minutes, the desired wet gel can be obtained. The molar ratio of aluminum isopropoxide, ethanol, nitric acid, acetone and aniline is 1:3.06:0.023:1.4:1.1. The wet gel was covered with a small amount of alcohol, aged for 1.5 days, and then replaced with alcohol three times for 24 hours each time.

[0033]Put the alumina wet gel into the supercritical drying equipment, take the partially hydrolyzed aluminum salt and tetraethyl orthosilicate mixed solution with a molar ratio of 8:1 and put it into an autoclave, and dry it supercritically at 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com