Compound binder and method of preparing mixed pellets for producing calcium carbide

A technology of binder and quicklime powder, which is applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of slow material transfer speed, low chemical reaction speed, high loss of organic carbon, etc., and achieve energy saving Effects of emission reduction, improvement of softening point, and increase of cohesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

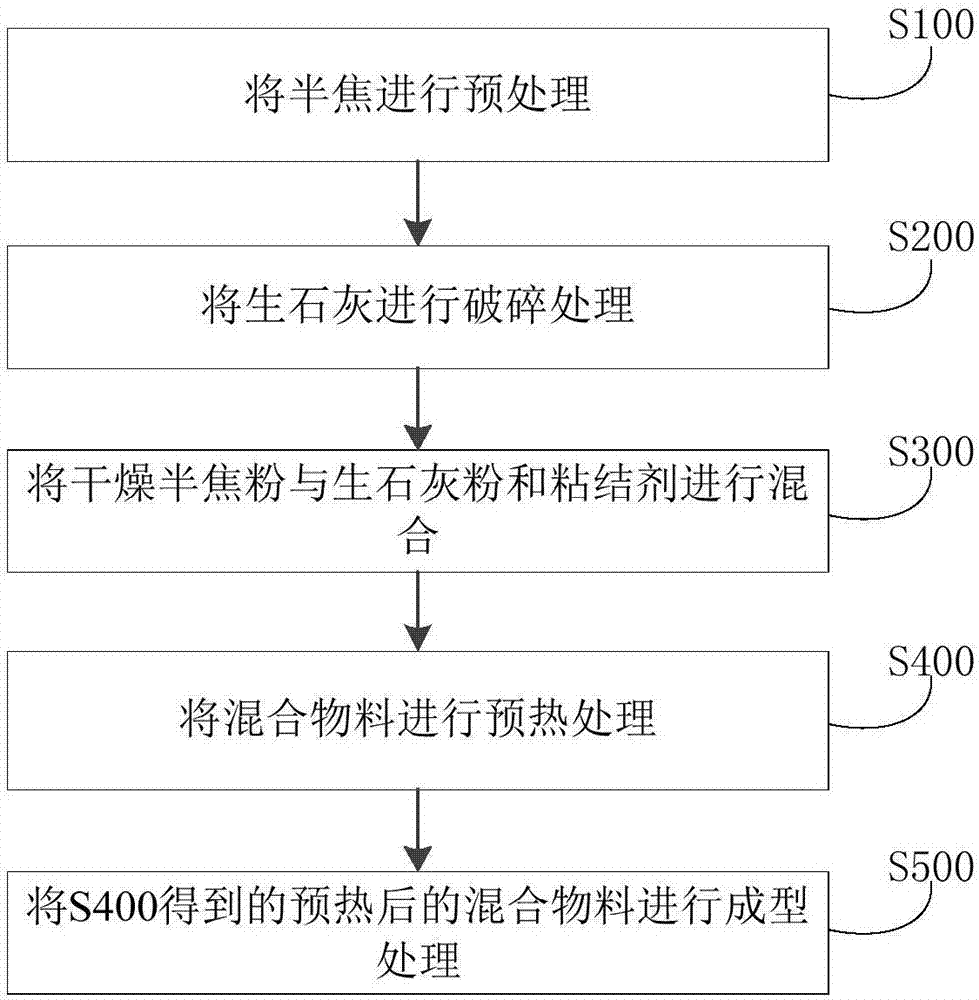

Method used

Image

Examples

Embodiment 1

[0055] (1) Composite binder: heat the asphalt to 200 degrees Celsius to obtain molten asphalt, then add 15wt% rubber powder with a particle size below 0.1mm to it, stir at a constant temperature for 2 hours, and then add 10wt% rubber powder with a particle size of Polyethylene glycol below 0.1 mm was stirred at constant temperature for 2 hours, cooled, and ground to obtain a composite binder.

[0056] (2) Method for preparing mixed pellets for production of calcium carbide

[0057] First, the semi-coke is crushed and dried sequentially to obtain dry semi-coke powder with a fixed carbon content of 78.27wt%, a moisture content of 5.66wt%, and a particle size of less than 1mm; then the quicklime is crushed to obtain a calcium oxide content of Quicklime powder with 89.39wt%, 3.14% burning loss and particle size below 1mm; weigh 1000g of dry semi-coke powder, 1600g of quicklime powder and 130g of composite binder, place them in a mixing device, and mix for 10min to obtain a mixed m...

Embodiment 2

[0059] (1) Composite binder: heat the asphalt to 200 degrees Celsius to obtain molten asphalt, then add 25wt% rubber powder with a particle size below 0.1mm to it, stir at a constant temperature for 2 hours, and then add 5wt% rubber powder with a particle size of Polyethylene glycol below 0.1 mm was stirred at constant temperature for 2 hours, cooled, and ground to obtain a composite binder.

[0060] (2) Method for preparing mixed pellets for production of calcium carbide

[0061] First, the semi-coke is crushed and dried sequentially to obtain dry semi-coke powder with a fixed carbon content of 78.27wt%, a moisture content of 5.66wt%, and a particle size of less than 1mm; then the quicklime is crushed to obtain a calcium oxide content of Quicklime powder with 89.39wt%, 3.14% burning loss and particle size below 1mm; weigh 1000g of dry semi-coke powder, 1600g of quicklime powder and 260g of composite binder, place them in a mixing device, and mix for 10min to obtain a mixed ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com