Silicon-based negative electrode material for inhibiting crack formation in lithium intercalation and deintercalation process and preparation method of silicon-based negative electrode material

A silicon-based negative electrode material, silicon-based material technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of poor structural stability and poor structural stability of ternary materials, and achieve the advantages of lithium intercalation and delithiation, The effect of improving conductivity and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

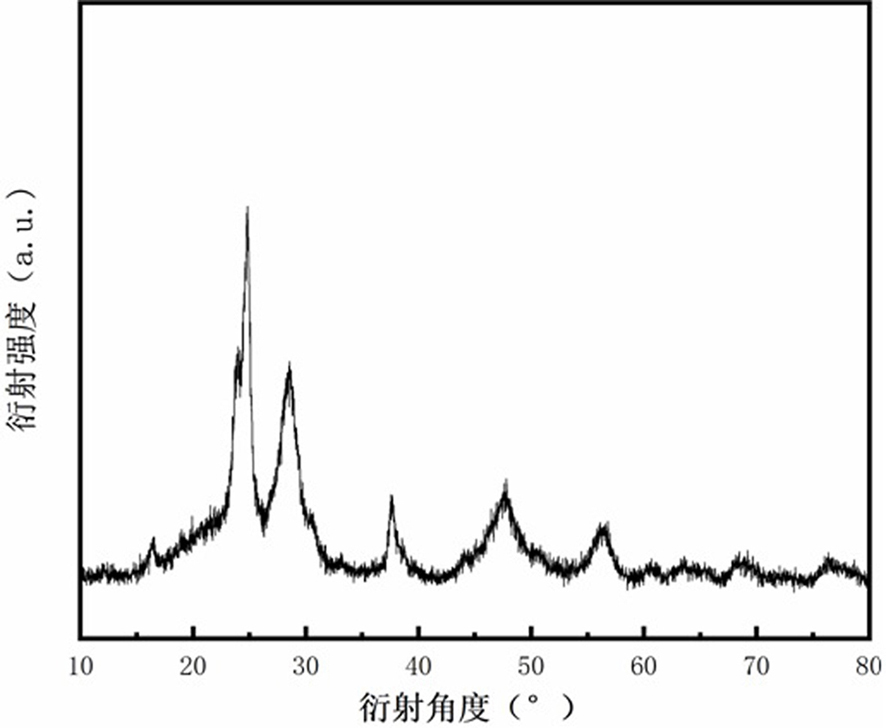

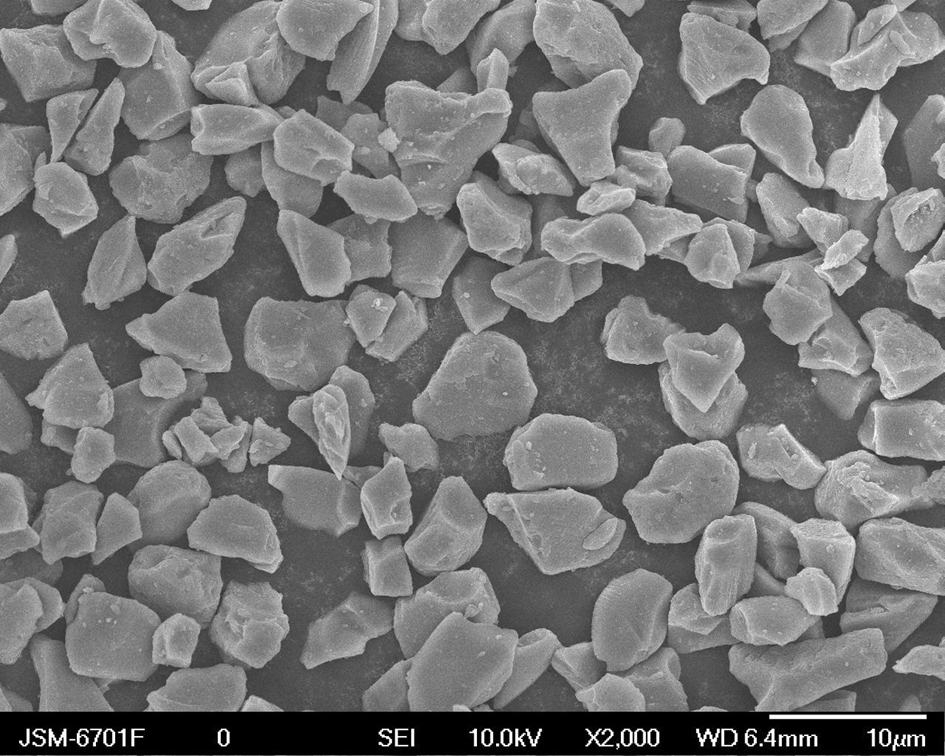

[0051] (1) Accurately weigh 10g of silicon oxide material (with a particle size of about 5µm) and 1g of lithium borohydride into a ball mill for mixed ball milling. The speed of the mixed ball mill is 550rpm, and the milling time is 7h.

[0052] (2) After the mixture obtained in step (1) is ball milled and mixed evenly, the mixed material is placed in a tube furnace for sintering under the protection of argon (gas flow rate is 150mL / min), and the heating rate is 5°C / min Raise the temperature to 650°C, keep it warm for 7 hours, and grind it thoroughly after cooling.

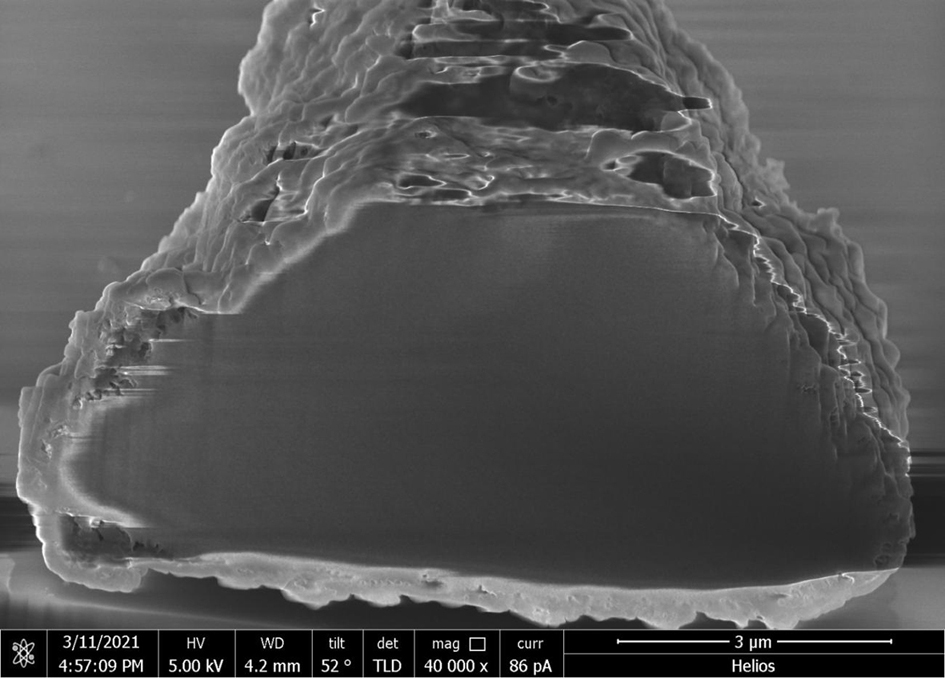

[0053] (3) According to LaCoO 3 Stoichiometric ratio, preparation of a perovskite precursor solution with a total metal concentration of 0.1M: dissolving lanthanum nitrate and cobalt nitrate in deionized water and ethanol (volume ratio 1:1) to obtain a mixed solution, and then adding urea to the solution to obtain Precursor solution, in which the molar ratio of urea to metal cation is 20:1, urea makes the precurs...

Embodiment 2

[0057] The boron-doped silicon-based negative electrode material was prepared according to the same method as in Example 1, except that in step (1), 15 g of silicon oxide material (with a particle size of about 5 μm) and 1 g of boron oxide were weighed and added to a ball mill Mixing ball milling is carried out, the rotation speed of the mixing ball milling is 500 rpm, and the time of ball milling is 5 hours. The thickness of the perovskite coating layer in the silicon-based negative electrode material is about 140-150 nm.

Embodiment 3

[0059] (1) Accurately weigh 10g of silica material (with a particle size of about 5µm) and 1g of aluminum nitrate into a ball mill for mixed ball milling. The speed of the mixed ball mill is 550rpm, and the milling time is 7h.

[0060] (2) After ball milling and mixing evenly, put the mixed material into a tube furnace for sintering under the protection of argon (gas flow rate of 150mL / min), raise the temperature to 650°C at a heating rate of 5°C / min, and keep it warm. 7h, fully ground after cooling.

[0061] (3) According to LaCoO 3 Stoichiometric ratio, prepare a perovskite precursor solution with a total metal concentration of 0.1M: dissolve lanthanum nitrate and cobalt nitrate in deionized water and ethanol (volume ratio 1:1) to obtain a mixed solution, and then add urea to the solution Obtain the precursor solution, in which the molar ratio of urea to metal cation is 20:1, urea makes the precursor evenly distributed and promotes the formation of the required perovskite p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com