Membrane for reciprocating hydraulic ore slurry membrane pump and manufacturing method thereof

A manufacturing method and technology of diaphragm pump, applied in the direction of variable displacement pump components, pumps, pump components, etc., can solve problems such as affecting the service life of hydraulic slurry pumps, low tear resistance and affecting the service life of diaphragms, etc. Achieve the effect of low flexural deformation stress, low strength failure sensitivity, and low surface friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

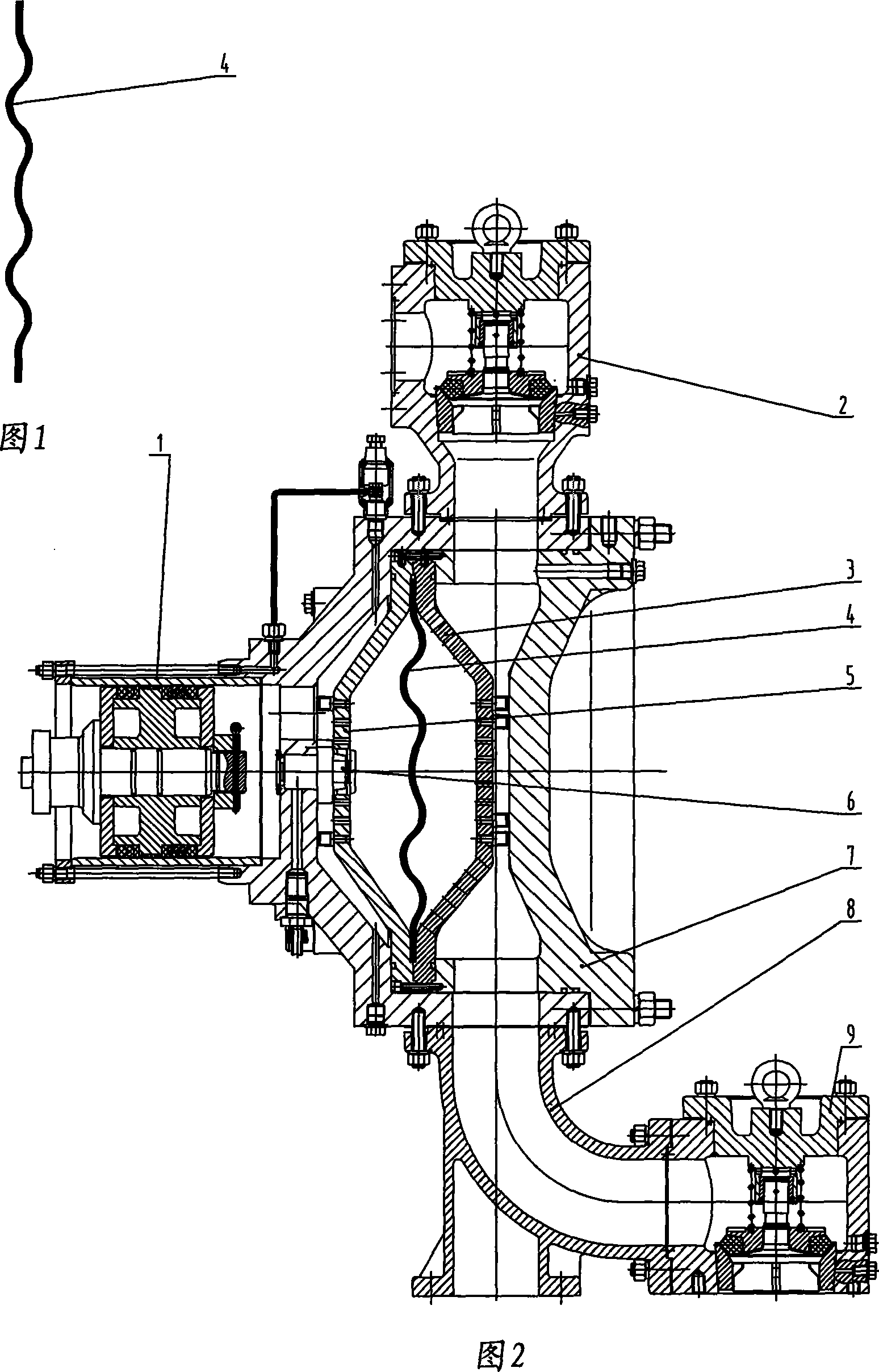

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] Polytetrafluoroethylene diaphragms are widely used in hydraulic diaphragm metering pumps, but they are all flat-shaped structures, and the diameter and thickness of the diaphragms are relatively small. Restrictions are also limited in terms of strength and deformation, which is the main reason why PTFE diaphragms have not been used in reciprocating hydraulic diaphragm pumps for a long time.

[0025] Considering the abrasiveness and conveying temperature of the pulp medium, the present invention adopts polytetrafluoroethylene with a relatively large thickness as the diaphragm material and molds it into an annular corrugated shape, as shown in Figure 1, and utilizes the ductility of the corrugated busbar to increase the deformation space. Under the same chamber diameter, the chamber volume is designed to be 3 to 5 times that of the flat diaphragm. Since the expanded l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com