Vertical hydraulic inner tube slurry pump

A mud pump and inner tube technology, applied in the field of vertical hydraulic inner tube mud pumps, can solve the problems of low mechanical efficiency, high frequency of operation, and short life, and achieve the effects of reduced volume and quality, long service life, and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

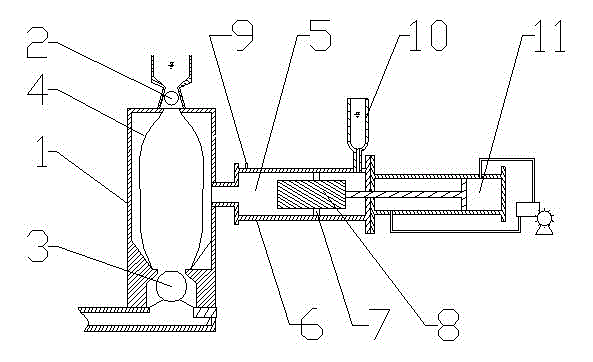

[0021] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 As shown, this kind of vertical hydraulic inner tube mud pump includes an upright mortar cylinder 1, the entrance of the upper end of the mortar cylinder 1 is provided with an inlet one-way floating ball valve 2 that can only enter and exit, and the outlet of the lower end of the mortar cylinder 1 is provided with The densities of the outlet one-way floating ball valve 3, the inlet one-way floating ball valve 2 and the outlet one-way floating ball valve that only go out but not in are all less than 1 kg / m3, preferably 0.94 kg / m3. Between the inlet and the outlet, a cylindrical mortar inner tube 4 is arranged. The mortar inner tube 4 is preferably made of elastic rubber. The inlet and outlet are sealed respectively, and the mortar inner tube 4 divides the inner cavity of the mortar cylinder 1 into two cavities, one is the cavity in the mortar inner tube 4, and this cavity communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com