Composite material for water lubricated bearing and preparation method thereof

A technology for water-lubricated bearings and composite materials, which is applied in the field of composite materials for water-lubricated bearings, can solve the problems of high polarity of nitrile rubber, cannot be used for a long time, and reduce wear resistance, and achieves good heat resistance and low wear rate. , The effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

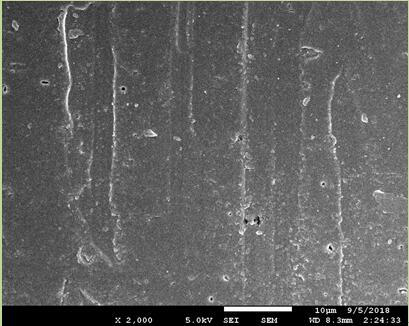

Embodiment 1

[0023] Embodiment 1 formula component

[0024] An embodiment of the present invention provides a composite material for water-lubricated bearings, which includes the following raw materials in parts by weight:

[0025] 100 parts of nitrile rubber, 50 parts of carbon black N550, 5 parts of zinc oxide, 1 part of stearic acid, 1.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, N-cyclohexyl - 1.0 parts of 2-benzothiazole sulfenamide, 1.5 parts of insoluble sulfur, and 3 parts of basalt fiber.

[0026] Among them, the length of the basalt fiber is 3 mm, and the aspect ratio is 250:1.

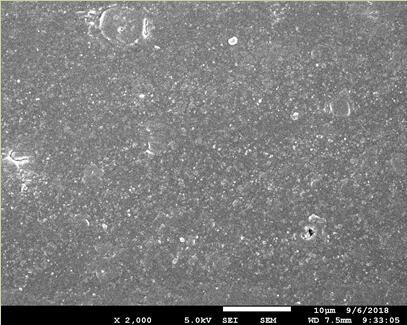

Embodiment 2

[0027] Embodiment 2 formula components

[0028] An embodiment of the present invention provides a composite material for water-lubricated bearings, which includes the following raw materials in parts by weight:

[0029] 100 parts of nitrile rubber, 50 parts of carbon black N550, 5 parts of zinc oxide, 1 part of stearic acid, 1.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, N-cyclohexyl - 1.0 parts of 2-benzothiazole sulfenamide, 1.5 parts of insoluble sulfur, and 12 parts of basalt fiber.

[0030] Among them, the length of basalt fiber is 4mm, and the aspect ratio is 360:1

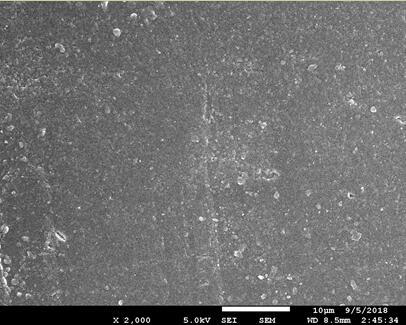

Embodiment 3

[0031] Embodiment 3 formula components

[0032] An embodiment of the present invention provides a composite material for water-lubricated bearings, which includes the following raw materials in parts by weight:

[0033] 100 parts of nitrile rubber, 50 parts of carbon black N550, 5 parts of zinc oxide, 1 part of stearic acid, 1.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, N-cyclohexyl - 1.0 parts of 2-benzothiazole sulfenamide, 1.5 parts of insoluble sulfur, 20 parts of basalt fiber.

[0034] Among them, the length of the basalt fiber is 3 mm, and the aspect ratio is 300:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com