Combined getter

A getter, combined technology, used in thermal insulation, heat exchange equipment, pipeline protection, etc., can solve the problems of poor thermal stability, slow absorption of reducing gas, and small absorption capacity, and achieve good thermal stability and expansion. The maximum applicable temperature and the effect of reducing the influence of water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Co-precipitation method was used to prepare an oxidizing agent with an atomic ratio of Co and Cu of 6:1, a weight percentage of Au of 2%, and a weight percentage of Pt of 0.5%.

[0018]The crystalline BaO is crushed, ball milled and passed through a sieve smaller than 500 microns, and the weight ratio of BaO to the above oxidant is 5:1 and mixed evenly. The calcium-lithium alloy is smelted in vacuum, the weight percentage of calcium and lithium is 60:40, ball milled, and passed through a sieve less than 500 microns.

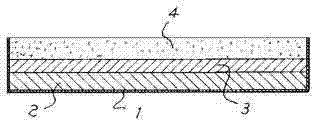

[0019] Put about 1 g of the above-mentioned calcium-lithium alloy powder at the bottom of a stainless steel container, then add about 1 g of BaO powder, and finally add about 3 g of mixed powder of oxidant and barium oxide. After applying pressure to press the powder firmly, the getter is obtained. The structure of the getter is that there are three layers in the stainless steel carrier 1, wherein the surface layer is a mixture 4 of oxidant and g...

Embodiment 2

[0020] Example 2 Co-precipitation was used to prepare an oxidizing agent with an atomic ratio of Fe and Ni of 2:5, 0.5% by weight of Au, 0.5% by weight of Pt, and 2% by weight of Pd. The crystalline CaO was crushed, ball milled and passed through a screen smaller than 500 microns. The barium-magnesium alloy is smelted in vacuum, the weight percentage of barium and magnesium is 57:43, and it is milled into powder.

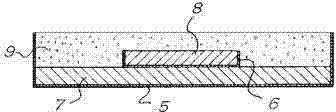

[0021] Put about 400 mg of the above-mentioned barium-magnesium alloy powder in a stainless steel container, and fix it with a little pressure. In another larger stainless steel container, add about 1g of the above-mentioned oxidizing agent, then put into the stainless steel container that barium-magnesium alloy is housed, finally add about 4g of calcium oxide powder. After applying pressure to press the powder firmly, it will be as figure 2 As shown in the getter, the structure of the getter is that there are three layers in the larger stainless steel carrier 5,...

Embodiment 3

[0022] Example 3 The oxidizing agent, barium-magnesium alloy powder, and calcium oxide powder in Example 2 were prepared. The weight ratio of calcium oxide powder to the oxidizing agent in the above-mentioned Example 2 is 5:1 and mixed evenly to obtain a mixed powder of oxidizing agent and calcium oxide.

[0023] Put about 1g of the above-mentioned barium-magnesium alloy powder in a stainless steel container, then add about 1g of calcium oxide powder, and finally add about 4g of the mixed powder of the above-mentioned oxidant and calcium oxide, and press the powder firmly to obtain

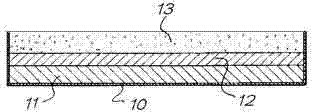

[0024] as image 3 As shown in the getter, the structure of the getter is that there are three layers in the stainless steel carrier 10, wherein the surface layer is a mixture 13 of the oxidant and the getter material calcium oxide, the bottom layer is the getter material barium-magnesium alloy 11; the middle layer is calcium oxide 12 (Such as image 3 shown). Compared with the prior art, the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com