On-line detection sensor for content of ferromagnetic abrasive particles in lubricating oil

A detection sensor and ferromagnetic technology, applied in the field of measuring instruments, can solve the problem of inability to distinguish the particle size of the ferromagnetic particles to be measured, and achieve the effects of reducing detection costs, expanding application fields, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

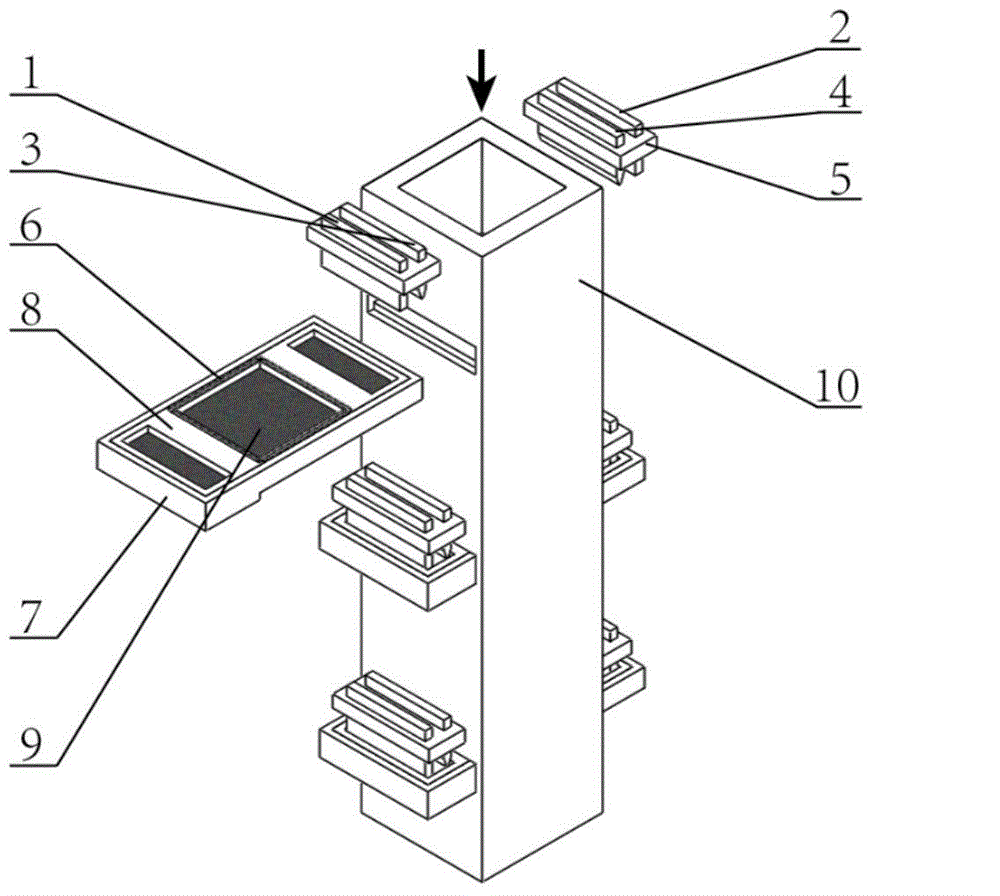

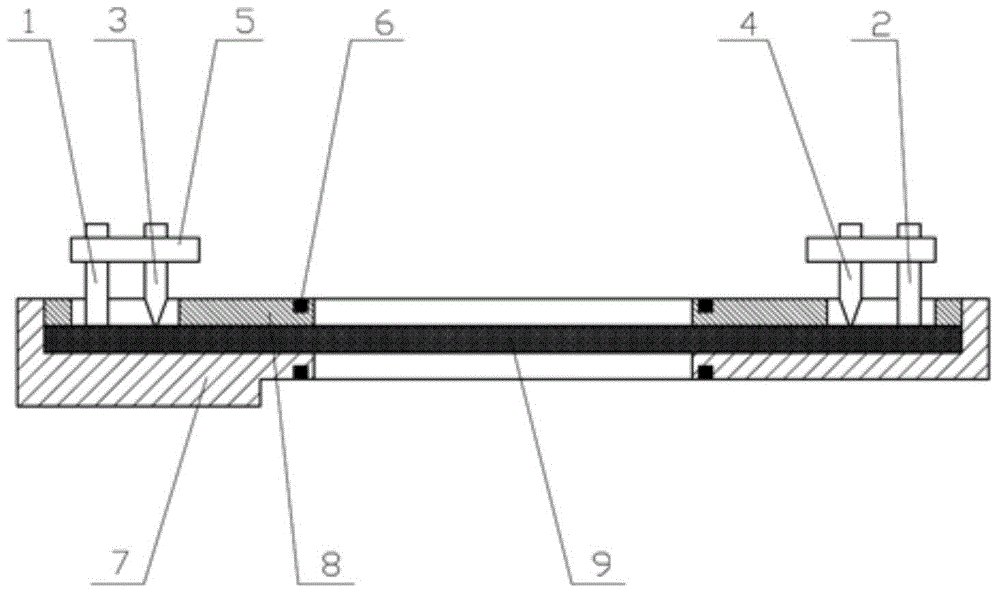

[0023] The on-line detection sensor of the content of ferromagnetic abrasive particles in the lubricating oil liquid proposed by the present invention, its structural schematic diagram is as follows figure 1 As shown, it includes filter 9 , filter lower splint 7 , filter upper splint 8 , current input electrode 1 , current output electrode 2 , front detection electrode 3 and rear detection electrode 4 . The filter disc 9 is fixed between the filter disc lower clamping plate 7 and the filter disc upper clamping plate 8, and the center of the filter disc lower clamping plate 7 and the filter disc upper clamping plate 8 respectively has an oil channel 10 (such as figure 2 shown in ) the same size square hole. There are square holes on the left side and right side of the filter upper splint 8 respectively, the current input electrode 1 and the front detection electrode 3 are respectively fixed in the left square hole of the filter upper splint 8 through the electrode fixing plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com