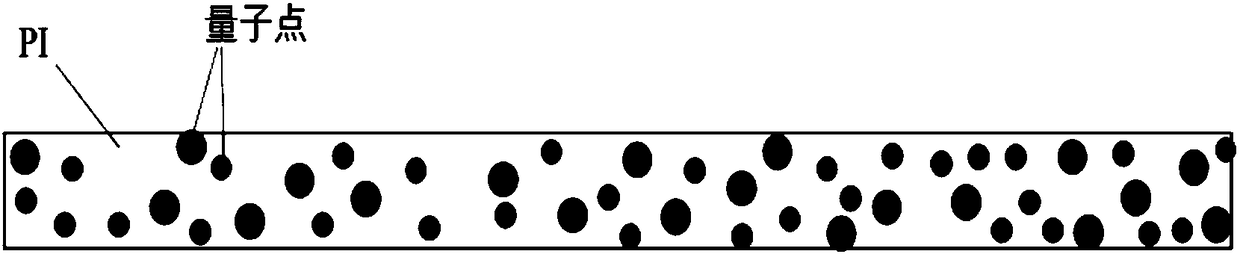

Preparation method of polyimide quantum dot backlight film

A polyimide, quantum dot technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as unfavorable long-term use, and achieve the effects of excellent bending resistance, good mechanical properties, and wide applicable temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

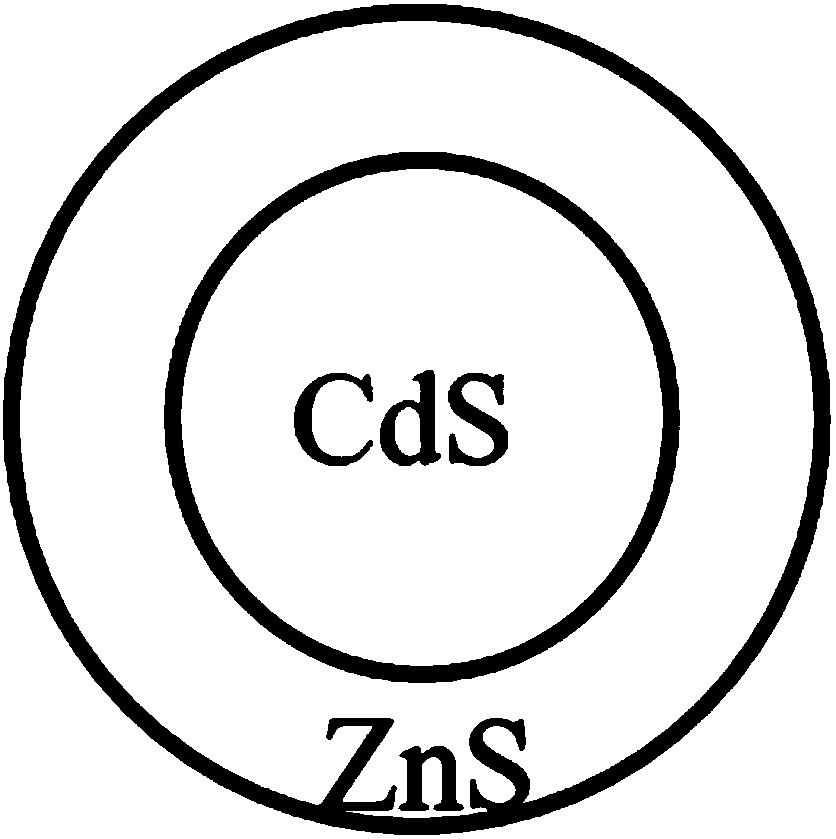

[0042] A preparation method for a polyimide quantum dot backlight film, comprising the steps of:

[0043] 1) Introduce nitrogen gas into a 250mL three-neck flask equipped with a mechanical stirring device, first add 2.9112g (0.0091mol) 2,2'-bis(trifluoromethyl)diaminobiphenyl and 0.2422g (0.0009mol)1, Mixed diamines of 1'-bis(4-aminophenyl)cyclohexane followed by 62.56 g of ionic liquid 1,3-bis(2-methoxy-2-oxoethyl)imidazole tetrafluoroborate . Turn on the mechanical stirring and heat to make it dissolve. At this time, the temperature of the mixed solution in the three-neck flask is not higher than 50°C. After the mixed diamine is completely dissolved, add 3.1021g (0.01mol) 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride into the three-necked flask, stir for 10min, squeeze the nitrogen bag to make the three-necked flask Remove as much air as possible. The mixture in the three-necked flask was slowly heated up to 180° C., stirred at a constant temperature of 180° C. for...

Embodiment 2

[0047] A preparation method for a polyimide quantum dot backlight film, comprising the steps of:

[0048] 1) Introduce nitrogen gas into a 250mL three-neck flask equipped with a mechanical stirring device, first add 2.9112g (0.0091mol) 2,2'-bis(trifluoromethyl)diaminobiphenyl and 0.2422g (0.0009mol)1, Mixed diamines of 1'-bis(4-aminophenyl)cyclohexane followed by 62.56 g of ionic liquid 1,3-bis(2-methoxy-2-oxoethyl)imidazole tetrafluoroborate . Turn on the mechanical stirring and heat to make it dissolve. At this time, the temperature of the mixed solution in the three-neck flask is not higher than 50°C. After the mixed diamine is completely dissolved, add 3.1021g (0.01mol) 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride into the three-necked flask, stir for 10min, squeeze the nitrogen bag to make the three-necked flask Remove as much air as possible. The mixture in the three-necked flask was slowly heated up to 180° C., stirred at a constant temperature of 180° C. for...

Embodiment 3

[0052] A preparation method for a polyimide quantum dot backlight film, comprising the steps of:

[0053] 1) Introduce nitrogen gas into a 250mL three-neck flask equipped with a mechanical stirring device, first add 2.9112g (0.0091mol) 2,2'-bis(trifluoromethyl)diaminobiphenyl and 0.2422g (0.0009mol)1, Mixed diamines of 1'-bis(4-aminophenyl)cyclohexane followed by 62.56 g of ionic liquid 1,3-bis(2-methoxy-2-oxoethyl)imidazole tetrafluoroborate . Turn on the mechanical stirring and heat to make it dissolve. At this time, the temperature of the mixed solution in the three-neck flask is not higher than 50°C. After the mixed diamine is completely dissolved, add 3.1021g (0.01mol) 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride into the three-necked flask, stir for 10min, squeeze the nitrogen bag to make the three-necked flask Remove as much air as possible. The mixture in the three-necked flask was slowly heated up to 180° C., stirred at a constant temperature of 180° C. for...

PUM

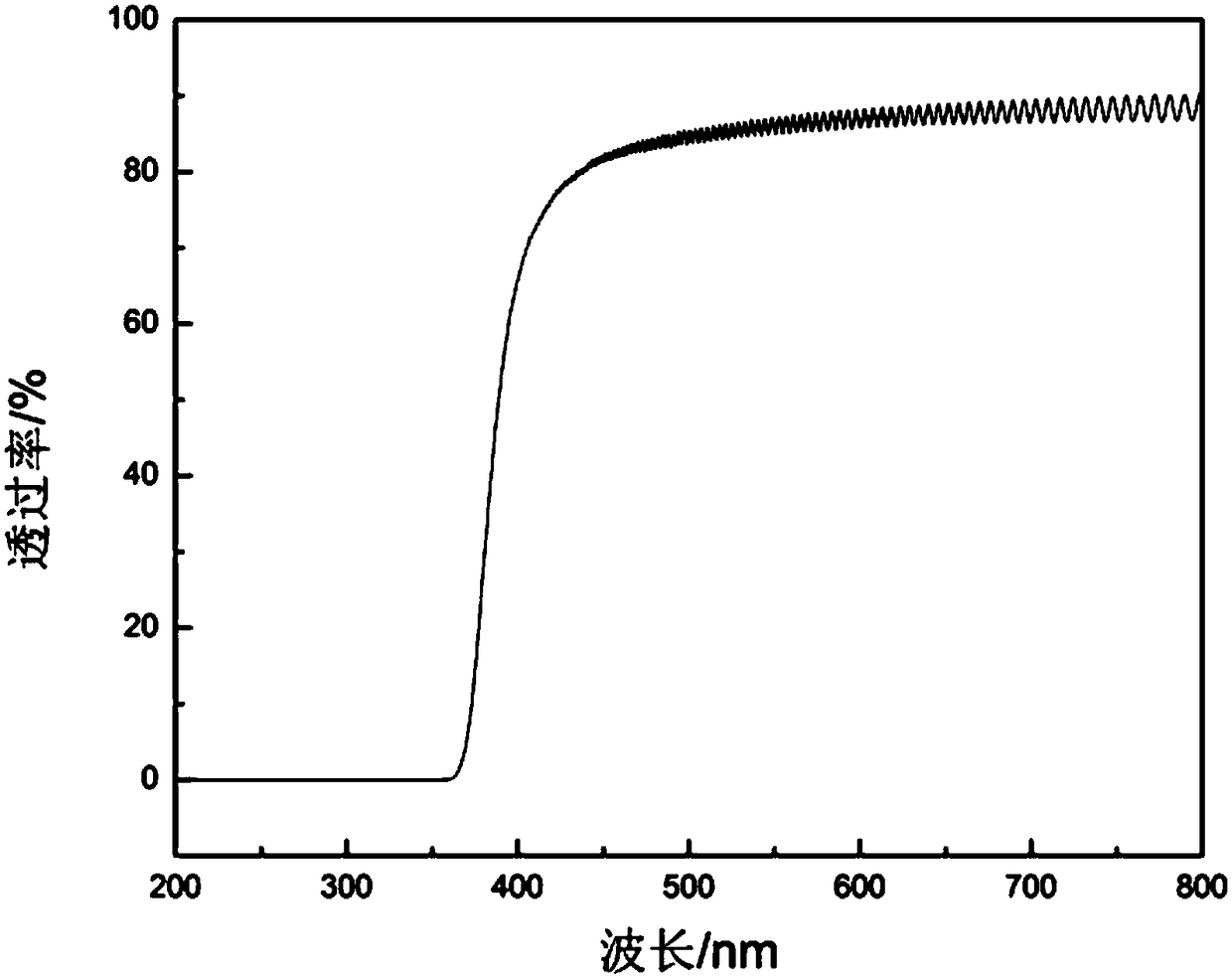

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com