Eddy current heating high temperature mechanical testing device

A technology of high-temperature mechanics and testing equipment, applied in the field of mechanical testing, can solve problems such as difficult to simulate thermal-mechanical shock conditions of high-temperature structures, narrow applicable temperature range of testing equipment, long-term heat transfer and heat preservation, etc., to achieve high testing accuracy and structural Compact and suitable for large temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

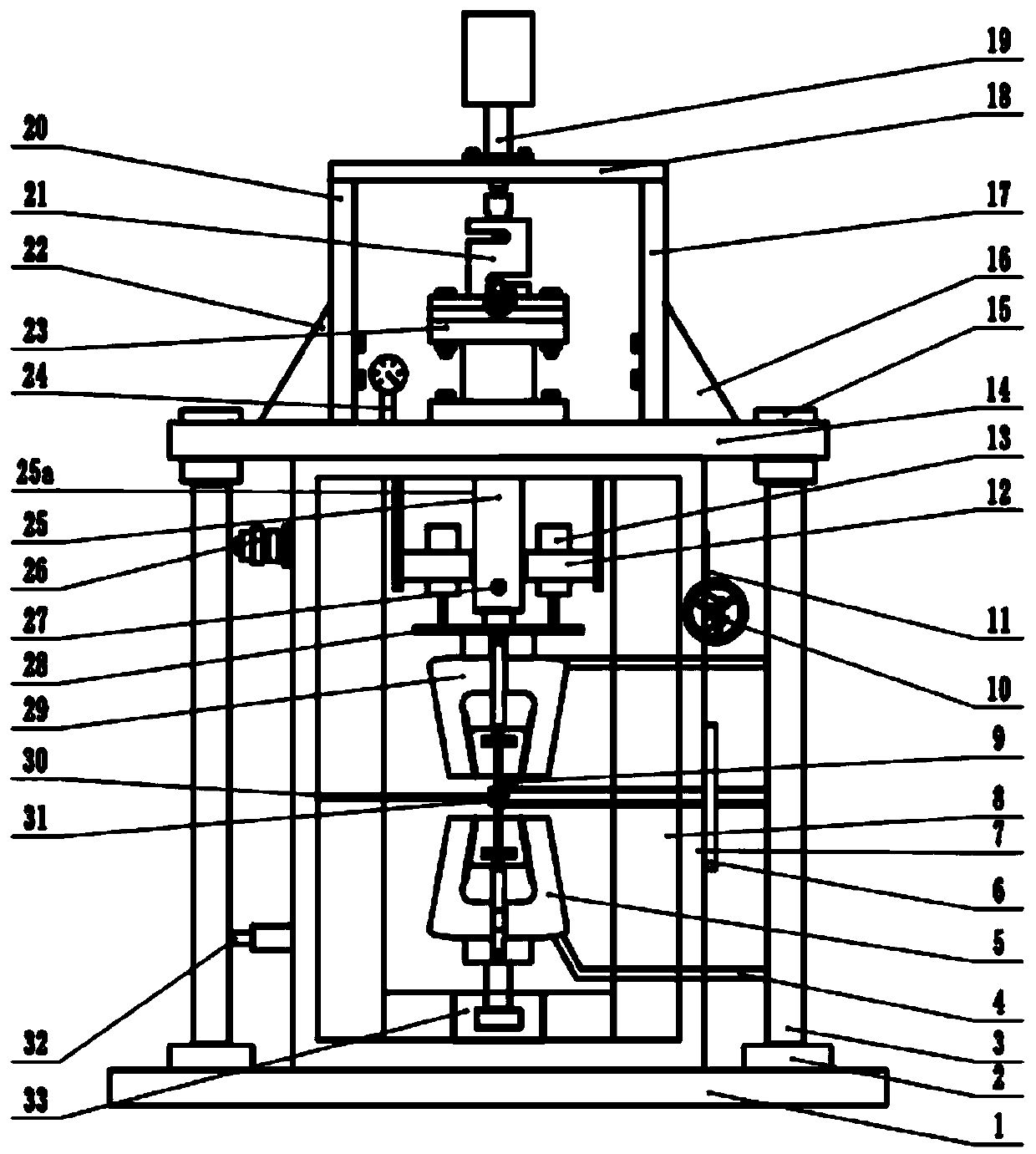

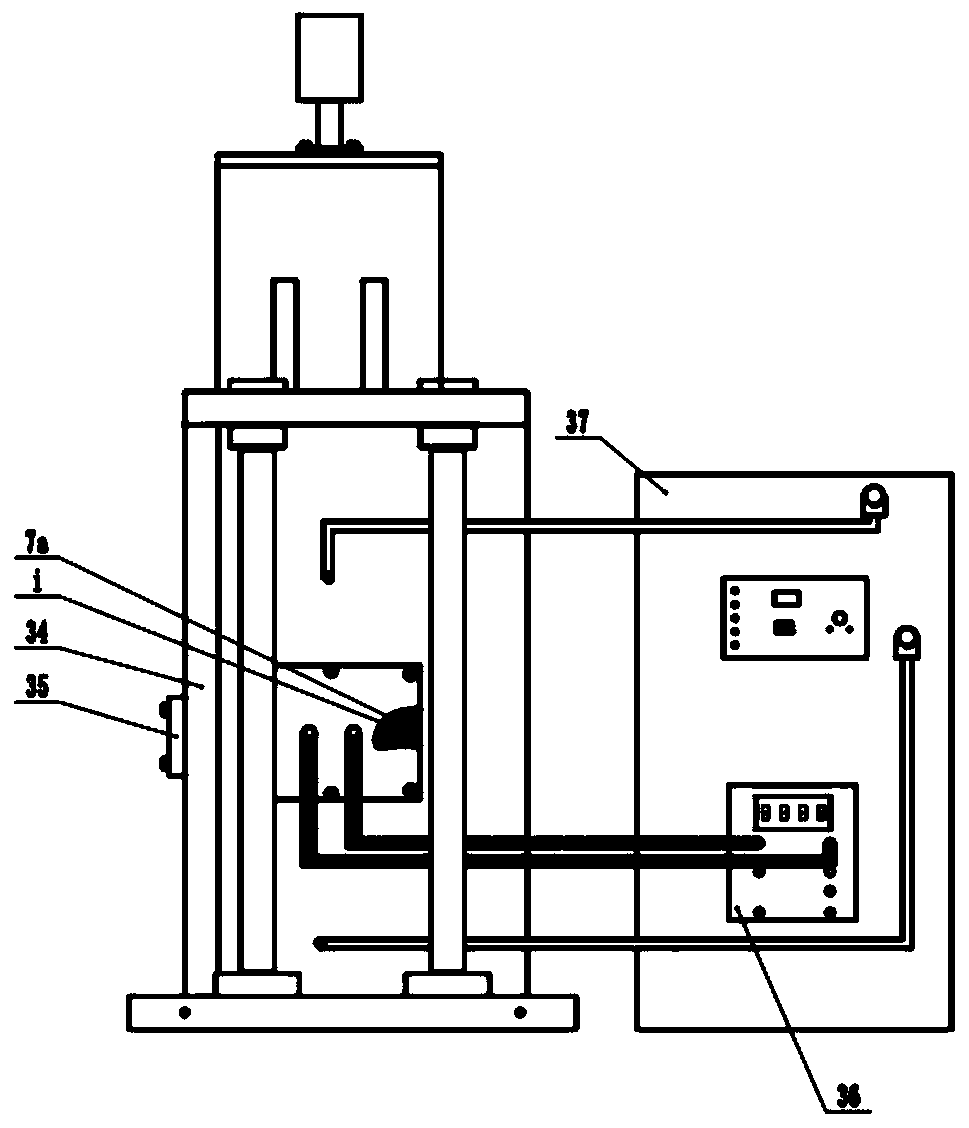

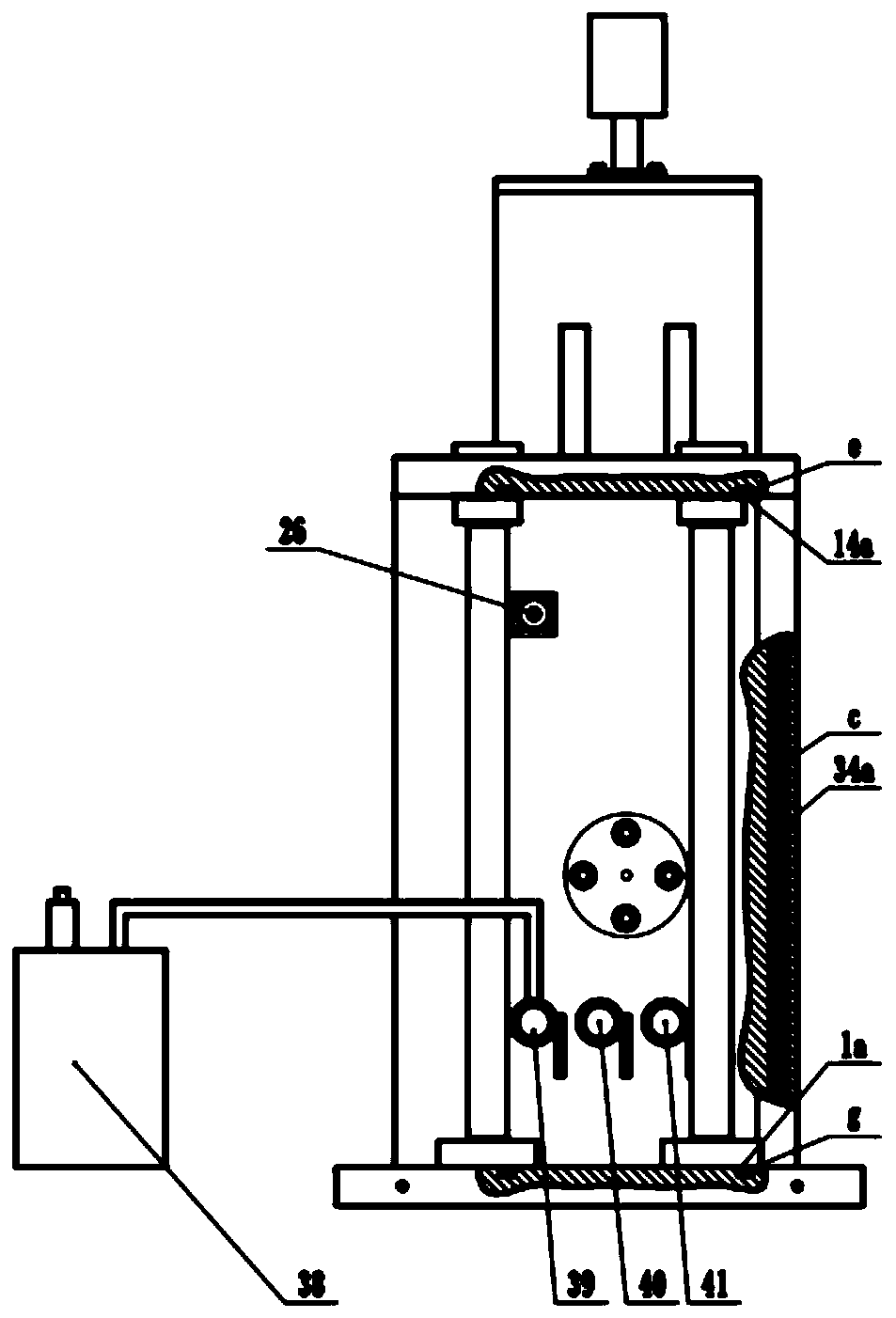

[0019] as attached figure 1 , 2 , 3, 4, 5, and 6, a kind of eddy current heating high-temperature mechanical testing device of the invention is composed of a clamping unit, a loading unit, a heating and cooling unit, an airtight box, and a reference frame.

[0020] The insulation material 8 is made of polycrystalline mullite fiber, and its temperature resistance limit is 2000°C. The force sensor 21 is an S-type force sensor with a measurement limit of 500kg and a sensitivity of 2.0000±0.0005mV / V. The temperature sensor 30 is a thermocouple with a temperature limit of 3500°C and an accuracy of ±0.5%t. The displacement sensor 13 is a linear variable differential transformer with a displacement limit of 10 mm and an accuracy of 1 μm.

[0021] During installation, the sample 9 is placed inside the eddy current coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com