Conductive liquid silicon rubber-based adhesive and preparation method for composition thereof

A silicone rubber composition, liquid silicone rubber technology, applied to conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of increased processing procedures, limited application fields, low modulus strength, etc., and achieves less material loss, The effect of outstanding electrical conductivity and short production process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

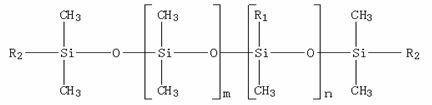

Image

Examples

Embodiment 1

[0045] Add 100 parts by mass of α,ω-divinyl polydimethylsiloxane (viscosity at 25°C: 3000 mPa·s) and 60 parts by mass of fumed silica (specific surface area: 150 m 2 / g), 20 parts by mass of silver powder (average particle size 20 microns), 25 parts by mass of hexamethyldisilazane, the material was stirred at room temperature for 2.0 hours, heated to a material temperature of 140°C, heated and kneaded for 2.0 hours, vacuum After de-lowering for 4 hours, 80 parts by mass of the above-mentioned α,ω-divinyl polydimethylsiloxane and 20 parts by mass of silicone resin (e) were added, mixed evenly, ground by a three-roll machine, and filtered. Finally, the liquid silicone rubber base compound is obtained.

[0046] Add 0.05 parts by mass of 1% isopropanol solution of chloroplatinic acid to 100 parts by mass of the liquid silicone rubber base compound, stir evenly, remove air bubbles, and filter to obtain component (A).

[0047] In 100 parts by mass of liquid silicone rubber base com...

Embodiment 2

[0056] Add 100 parts by mass of α,ω-allyldimethyl polydimethylsiloxane (viscosity at 25°C: 10,000 mPa·s) and 50 parts by mass of fumed silica (specific surface area 200m 2 / g), 50 parts by mass of acetylene carbon black (average particle size 0.01 micron), 20 parts by mass of hexamethyldisilazane, the material was stirred at room temperature for 3.0 hours, heated to a material temperature of 160°C, heated and mixed for 6.0 hours, After vacuuming for 2.0 hours, 40 parts by mass of α,ω-allyldimethyl polydimethylsiloxane and 30 parts by mass of silicone resin (e) were added, mixed evenly, ground and filtered by a three-roll machine. Finally, the liquid silicone rubber base compound is obtained.

[0057] Add 0.2 parts by mass of 1% isopropanol solution of chloroplatinic acid to 100 parts by mass of the liquid silicone rubber base compound, stir evenly, remove air bubbles, and filter to obtain component (A).

[0058] Add 4.0 parts by mass of polymethylhydrogensiloxane (h) and 0.2...

Embodiment 3

[0067] Add 100 parts by mass of α,ω-butenyl dimethyl polydimethylsiloxane (viscosity at 25°C: 15000 mPa·s) and 30 parts by mass of precipitated silica (specific surface area 150m 2 / g), 40 parts by mass of acetylene carbon black (average particle size 0.1 micron), 15 parts by mass of dimethyldimethoxysilane, the material was stirred at room temperature for 5.0 hours, heated to a material temperature of 180 ° C, heated and mixed for 4.0 hours , and then add 100 parts by mass of α,ω-butenyl dimethylpolydimethylsiloxane and 60 parts by mass of silicone resin (e), mix well, grind and filter through a three-roll machine. Finally, the liquid silicone rubber base compound is obtained.

[0068] Add 0.5 parts by mass of 1% platinum diacetoacetate solution to 100 parts by mass of the liquid silicone rubber base compound, stir evenly, remove air bubbles, and filter to obtain component (A).

[0069] Add 6.0 parts by mass of polymethylhydrogensiloxane (h) and 0.5 parts by mass of 1-ethyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com