Method for preparing carbon/carbon-silicon carbide composite material for bearings

A composite material and silicon carbide technology, which is applied in the preparation of carbon/carbon-silicon carbide (C/C-SiC) composite materials for bearings, and in the field of high-performance composite material process preparation, can solve the problem of slow wear, high life, and inapplicability and other problems, to achieve the effect of improving wear resistance, reducing residual stress and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

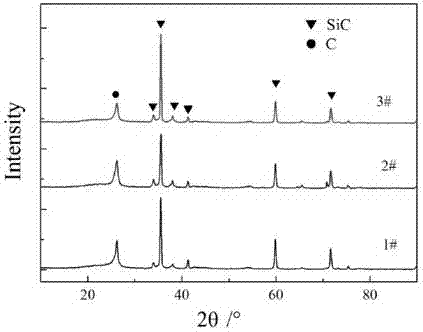

Embodiment 1

[0015] Put the non-woven carbon fiber integral mat made by alternately laminating the non-weft cloth and the net tire through needle punching into a heat treatment furnace, vacuumize, and carry out carbonization treatment at a temperature of 900-1000°C to obtain a density of 0.60g / cm 3 The non-weft cloth carbon fiber integral felt is put into the CVI furnace, with C 3 h 6 As a precursor, it is densified by CVI at a temperature of 900-1100°C, and the density is 1.30g / cm 3 The C / C porous preform is subjected to a high temperature treatment at 2350-2600°C under an Ar gas protective atmosphere. Resin impregnation, pressurization, after impregnation, put it in an oven for curing treatment, after curing, put it in a high-temperature furnace to vacuumize and carbonize at a temperature of 900-1000 ° C, after carbonization, put the material in a high-temperature furnace, under the protective atmosphere of Ar gas, The temperature is about 2250°C for high temperature heat treatment, an...

Embodiment 2

[0017] Put the carbon fiber integral felt made of polyacrylonitrile pre-oxidized fiber through needle punching into a heat treatment furnace, vacuumize, and carry out carbonization treatment at a temperature of 900-1000°C to obtain a density of 0.30g / cm 3 Carbon fiber integral felt, put the carbon fiber integral felt into the CVI furnace, and use C 3 h 6 As a precursor, it is densified by CVI at a temperature of 900-1100°C, and the density is 1.30g / cm 3 The C / C porous preform is subjected to a high temperature treatment at 2350-2600°C under an Ar gas protective atmosphere. Resin impregnation, pressurization, after impregnation, put it in an oven for curing treatment, after curing, put it in a high-temperature furnace to vacuumize and carbonize at a temperature of 900-1000 ° C, after carbonization, put the material in a high-temperature furnace, under the protective atmosphere of Ar gas, The temperature is about 2250°C for high temperature heat treatment, and the density is 1...

Embodiment 3

[0019] Put the carbon fiber integral felt made of polyacrylonitrile pre-oxidized fiber through needle punching into a heat treatment furnace, vacuumize, and carry out carbonization treatment at a temperature of 900-1000°C to obtain a density of 0.30g / cm 3 Carbon fiber integral felt, put the carbon fiber integral felt into the CVI furnace, and use C 3 h 6 As a precursor, it is densified by CVI at a temperature of 900-1100°C, and the density is 1.30g / cm 3The C / C porous preform is subjected to a high temperature treatment at 2350-2600°C under an Ar gas protective atmosphere. Resin impregnation, pressurization, after impregnation, put it in an oven for curing treatment, after curing, put it in a high-temperature furnace to vacuumize and carbonize at a temperature of 900-1000 ° C, after carbonization, put the material in a high-temperature furnace, under the protective atmosphere of Ar gas, The temperature is about 2250°C for high temperature heat treatment, and the density is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com