Liquid cooling LED lamp

A LED lamp, liquid cooling technology, applied in the direction of lampshade, cooling/heating device of lighting device, lighting and heating equipment, etc., can solve the problem that the temperature of the chip cannot be effectively controlled, the heat cannot be transferred in a timely manner, and the heat dissipation effect is not good. Ideal and other issues, to achieve the effect of improving heat dissipation, improving light output efficiency, and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to introduce the present invention in more detail, the structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

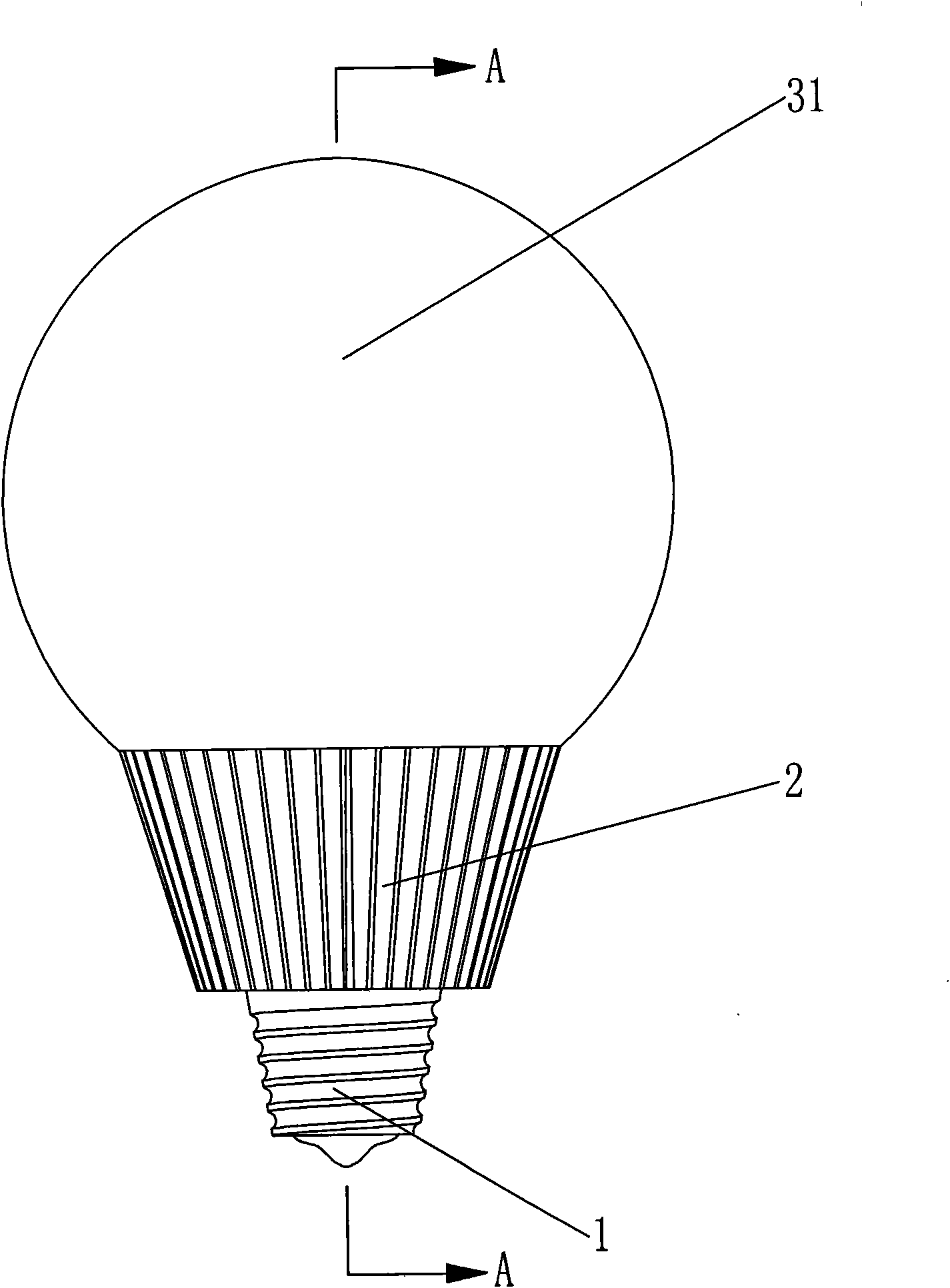

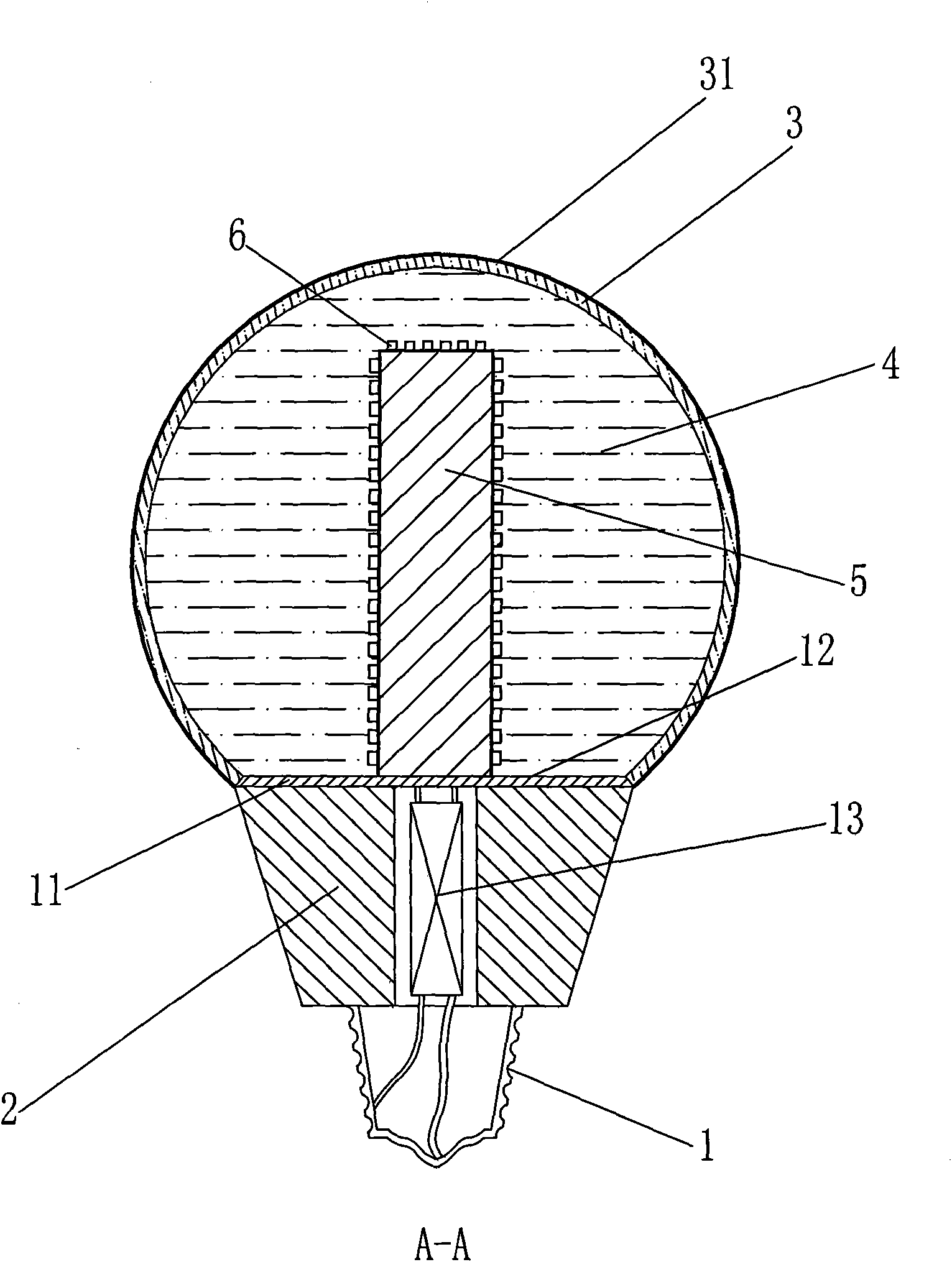

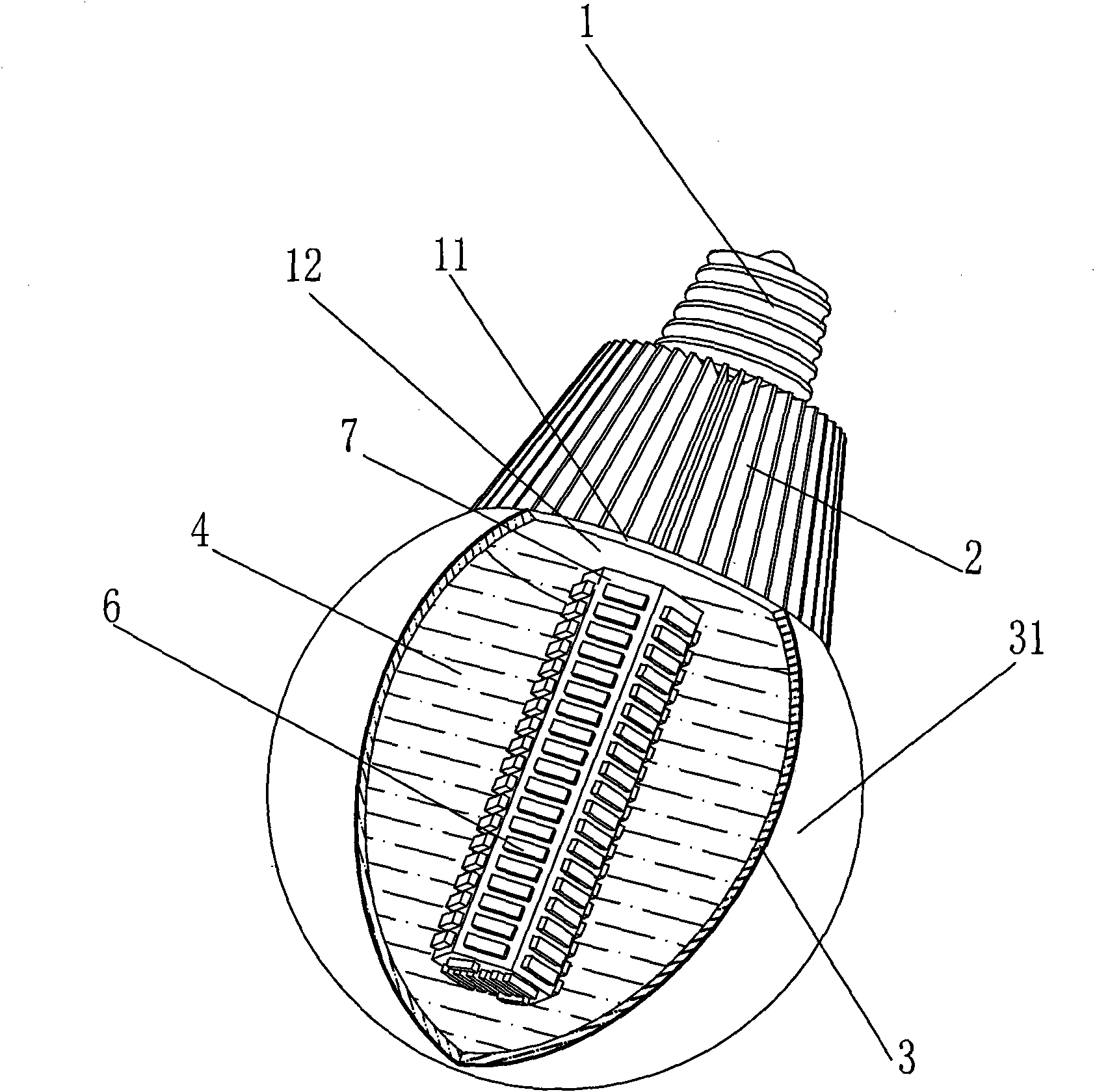

[0017] Such as figure 1 , 2 , 3, and 4: the present invention includes a lamp holder 1, a heat sink 2 arranged on the lamp holder 1, a heat conduction column 5 fixed on the heat sink 2, and the LED 6 is directly fixed on the flexible circuit board 7 in advance. The light-emitting chip can be directly packaged on the flexible circuit board 7 with a pre-printed circuit, and then the flexible circuit board 7 with multiple LEDs 6 in the array is wound and fixed on the side and top surface of the heat-conducting column 5 through heat-conducting glue (not shown). , a light-transmitting outer cover 3 is made on the periphery of the LED 6 and fixed on the heat sink 2, filling the cavity formed by the outer cover 3 and the heat sink 2 with a liquid 4, and the heat sink 2 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com