Positive injection back squeeze well cementation method for low pressure and leaky well

A lost well and low pressure technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of low replacement efficiency of sealing section and insufficient cement return height, etc., so as to avoid significant cost increase, The effect of improving cementing quality and avoiding production hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Well JP-302 was cemented using the above-mentioned cementing method of forward injection and reverse extrusion for low-pressure and easy-to-lose wells. Loss occurred during normal cementing in Well JP-302, and the return height of the cement slurry was insufficient, so back extrusion was carried out.

[0098] The technical casing of Well JP-302 lost when running the casing, and the drilling fluid established normal circulation after plugging and before cementing. The cementing design and construction are carried out according to the one-time sealing of the whole well section. Leakage occurs during the cement replacement process. According to the leakage amount and the pressure before collision, it is estimated that the cement return height is 1500m; after waiting for 12 hours, inject 10m of flushing fluid 3 , "back extrusion" cement slurry 30m 3 . Such as image 3 As shown, the sound amplitude logging shows that the unconnected well section of the annulus is only 70m...

Embodiment 2

[0100] Well JP-329 was cemented using the above-mentioned cementing method of forward injection and reverse extrusion for low-pressure and easy-to-lose wells. The drilling fluid in Well JP-329 could not establish normal circulation before cementing, so the design of "positive injection" and "back squeeze" was adopted.

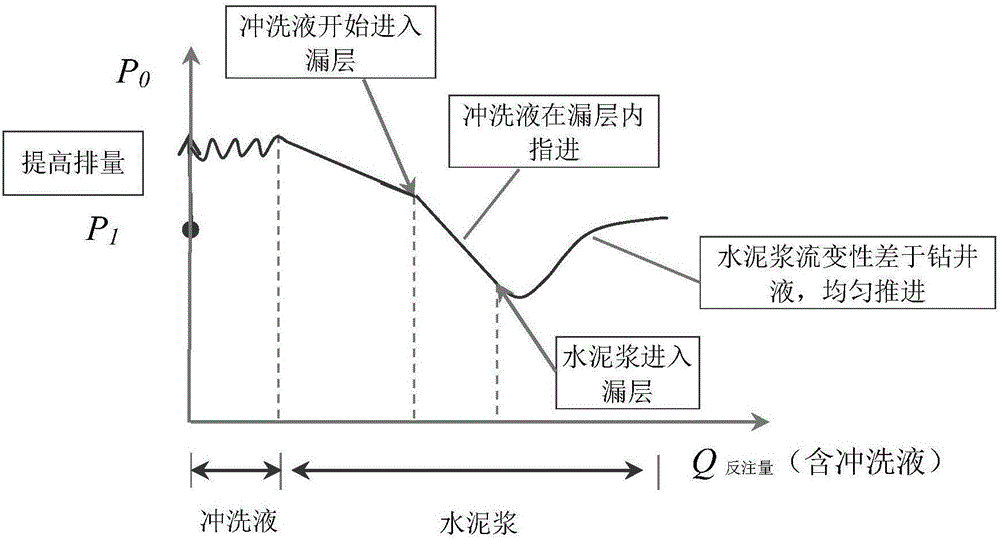

[0101] After the casing was run in Well JP-329, circulation could not be established due to severe leakage, and the thick slurry in the well could not circulate out of the well. The well was constructed by "positive injection and back extrusion". "Positive injection" is sealed to the bottom of the leakage layer, and the cement slurry is not added; after 12 hours of positive injection, back squeeze the flushing fluid, isolation slurry and low-density cement slurry in sequence. According to the wellhead pressure, after back-extruding part of the cement slurry, the pressure slowly drops to the minimum and then rises significantly, and the back-extrusion cement slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com