Carboxylated styrene-butadiene rubber latex special for oil and gas field cementing well

A carboxylated styrene-butadiene latex, oil and gas field technology, applied in the direction of drilling compositions, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

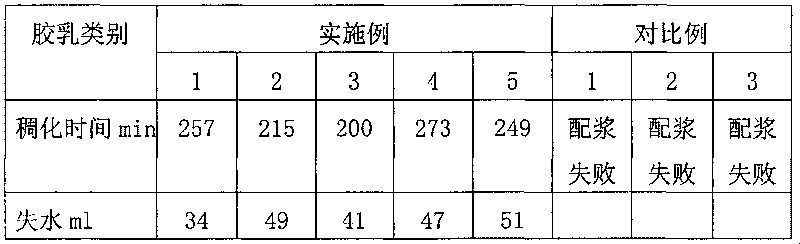

Examples

Embodiment 1

[0033] Synthesis of carboxylated styrene-butadiene latex: (based on 100 parts in total monomer addition)

[0034] 110 parts of deionized water, 0.60 parts of sodium dodecylsulfate, 0.60 parts of sodium dodecylbenzenesulfonate, and 0.60 parts of nonylphenol polyoxyethylene ether emulsifier were successively put into a 10L jacketed stirring kettle. Parts, Na 2 CO 3 0.30 parts, K 3 PO 4 0.16 parts, 55 parts of styrene, 2.5 parts of acrylic acid, 0.50 parts of (2-acrylamido-2-methyl) propylsulfonic acid, 0.65 parts of tertiary dodecyl mercaptan, 42 parts of butadiene, potassium persulfate Initiator 0.60 parts, heating up to maintain the reaction temperature at 68±3°C. Post-treatment is carried out when the conversion rate reaches above 98%. The various indicators of the latex synthesized at last are as follows:

[0035] Complex total solids

Embodiment 2

[0037]110 parts of deionized water, 0.70 parts of sodium lauryl sulfate, 0.40 parts of sodium dodecylbenzenesulfonate, 0.70 parts of nonylphenol polyoxyethylene ether, Na 2 CO 3 0.30 parts, K 3 PO 4 0.16 parts, 49 parts of styrene, 2.7 parts of acrylic acid, 0.3 parts of sodium p-styrene sulfonate, 0.48 parts of tert-dodecyl mercaptan, 48 parts of butadiene, 0.50 parts of ammonium persulfate initiator, and the temperature was raised to maintain the reaction temperature at 68 ±3°C, when the conversion rate reaches above 98%, post-treatment is carried out. The various indicators of the latex synthesized at last are as follows:

[0038] Carboxylated styrene-butadiene latex performance index

[0039] Complex total solids

Embodiment 3

[0041] 100 parts of deionized water, 0.80 parts of sodium lauryl sulfate, 0.40 parts of sodium dodecylbenzenesulfonate, and 0.60 parts of octylphenol polyoxyethylene ether were successively put into a 10L jacketed polymerization kettle. Na 2 CO 3 0.40 parts, K 3 PO 4 0.16 parts, 46 parts of styrene, 2.10 parts of methacrylic acid, 0.70 parts of (2-acrylamido-2-methyl) propyl sulfonic acid, 0.30 parts of tertiary dodecyl mercaptan, 52.2 parts of butadiene, over 0.45 parts of ammonium sulfate initiator, heat up to maintain the reaction temperature at 68±3°C, add 10 parts of deionized water, 0.20 parts of sodium dodecylbenzenesulfonate, and 0.20 parts of octylphenol polyoxyethylene ether when the reaction reaches 5 hours , maintain the reaction temperature at 68±3°C. When the conversion rate reaches 98%, residual monomers are removed, post-treatment is carried out, and filtration is performed. The various indicators of the latex synthesized at last are as follows:

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com