Drilling fluid additive capable of improving oil well cementing quality

A technology of oil well cementing and drilling fluid, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems such as difficult to guarantee the quality of cementing, and achieve the effect of promoting tight bonding, enhancing strength and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Ingredients according to the following recipe:

[0016] 50% of aluminum silicate whiskers, 20% of nano anatase titanium dioxide, 20% of magnesium-rich silicate mineral fibers, 5% of vinyl acetate, and 5% of sulfonated tannins can be mixed to obtain the petroleum drilling fluid of the present invention Additives, the amount added in the drilling fluid is 1%-3%. The effects of the drilling fluid additive on the cementing interface cementation strength and the main properties of the drilling fluid were investigated, and the results are shown in Table 1 and Table 2.

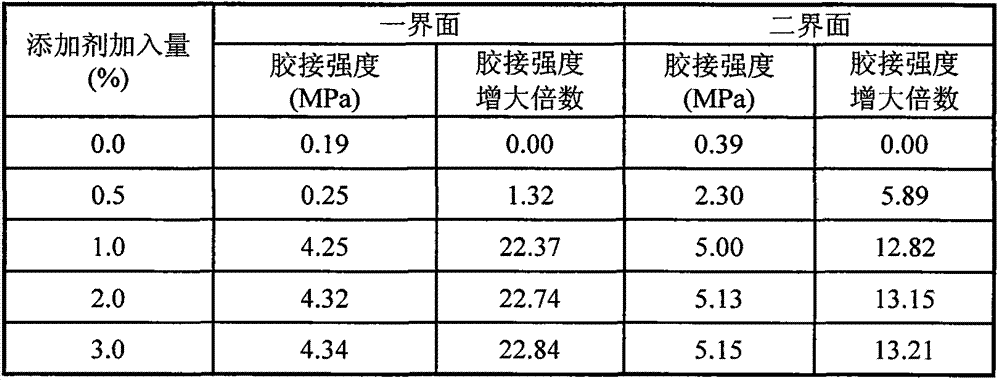

[0017] The impact of the oil drilling fluid additive of the present invention on the interface bond strength of table 1

[0018]

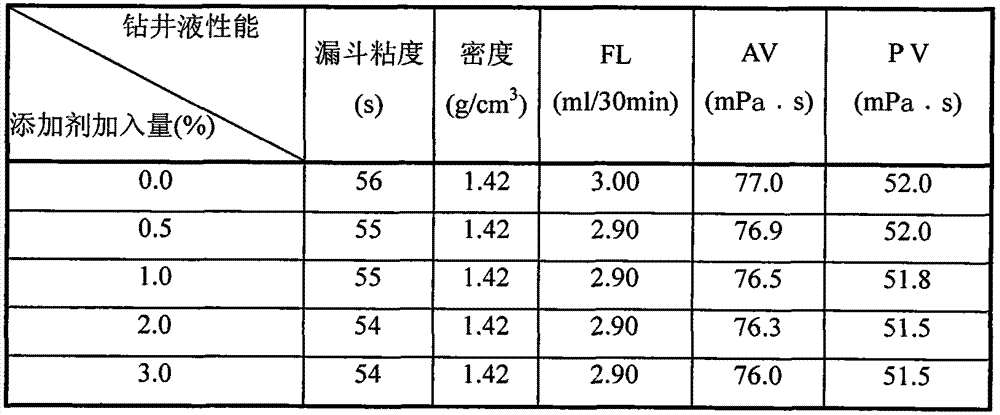

[0019] The impact of the oil drilling fluid additive of the present invention on the main properties of drilling fluid of table 2

[0020]

Embodiment 2

[0022] Ingredients according to the following recipe:

[0023] Calcium silicate whisker 30%, superfine rutile powder 50%, polyacrylonitrile 10%, polyacrylamide cross-linked body 5%, sulfonated humic acid 5%, after mixing, the petroleum drilling fluid of the present invention can be obtained Additives, the amount added in the drilling fluid is 1%-2%. The effects of the drilling fluid additive on the bonding strength of the cementing interface and the main properties of the drilling fluid were investigated, and the results are shown in Table 3 and Table 4.

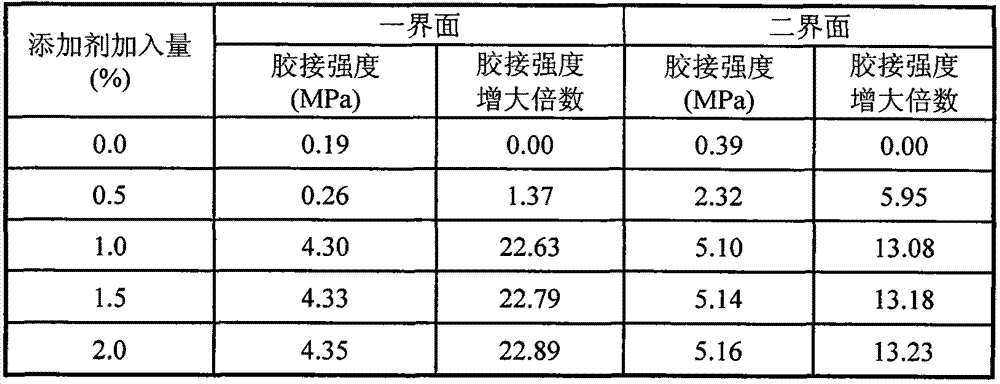

[0024] The influence of the oil drilling fluid additive of the present invention on the interface bond strength of table 3

[0025]

[0026] The influence of the petroleum drilling fluid additive of the present invention on the main performance of drilling fluid of table 4

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com