Hydraulic chambering device for drilling

A hydraulic and drilling technology, which is applied in drilling equipment, drilling equipment and methods, earthwork drilling and production, etc., and can solve problems such as water eye blockage, suffocation, and blade cannot be retracted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

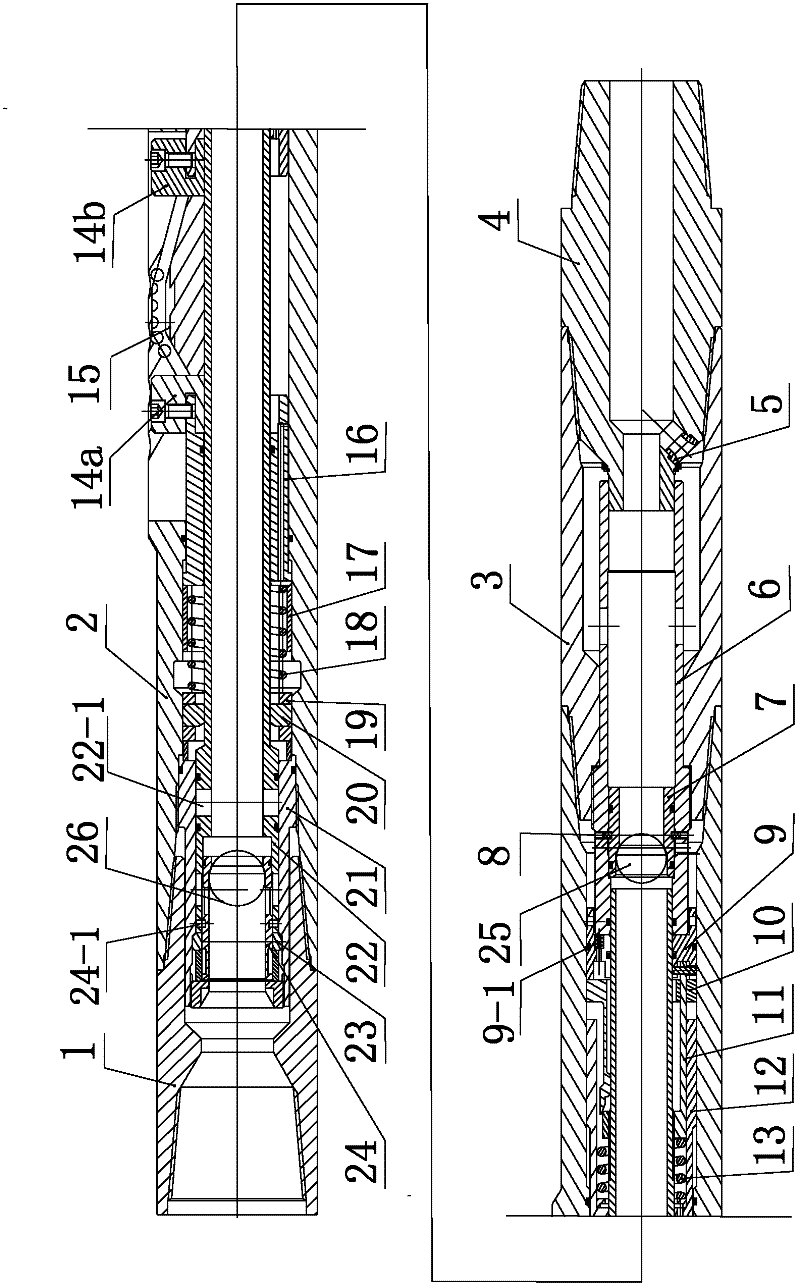

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

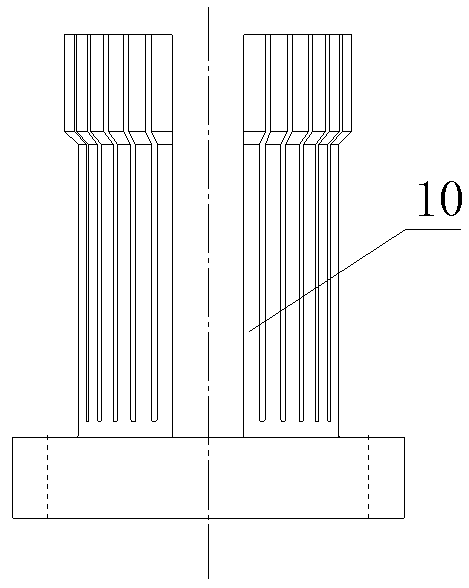

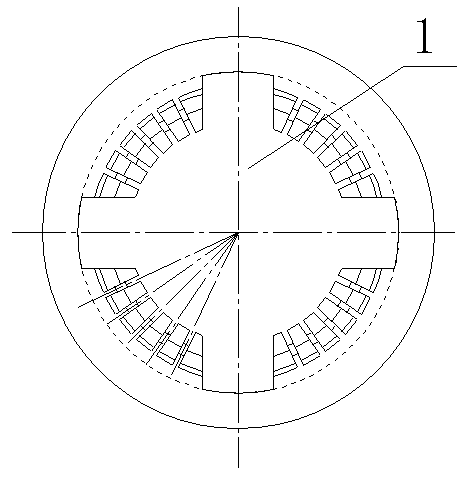

[0030] see Figure 1-Figure 10 , the well completion hydraulic reaming device, comprising an upper joint 1, a casing 2, a lower casing 3 and a lower joint 4 which are sequentially connected by threaded buckles, a mandrel 22 is arranged in the upper joint and the housing, and a mandrel 22 is arranged on the side of the lower joint 4 There are three nozzles 5, and a sealing tube 6 sealingly connected with the mandrel 22 is arranged in the lower casing, and a pressure transmission hole is formed on the sealing tube 6. A piston 9 is installed between the housing and the mandrel, and a built-in nozzle 9-1 is formed on the axial direction of the piston to prevent cuttings from jamming the blade. One end of the piston is connected with a locking an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com