A pipeline deflagration flame arrester

A flame arrester and pipeline technology, used in fire rescue and other directions, can solve the problems of unreliable fire resistance, easy blockage, and large fluid resistance of the flame arrester, and achieve the effect of clear function division, easy maintenance, and high fire resistance reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

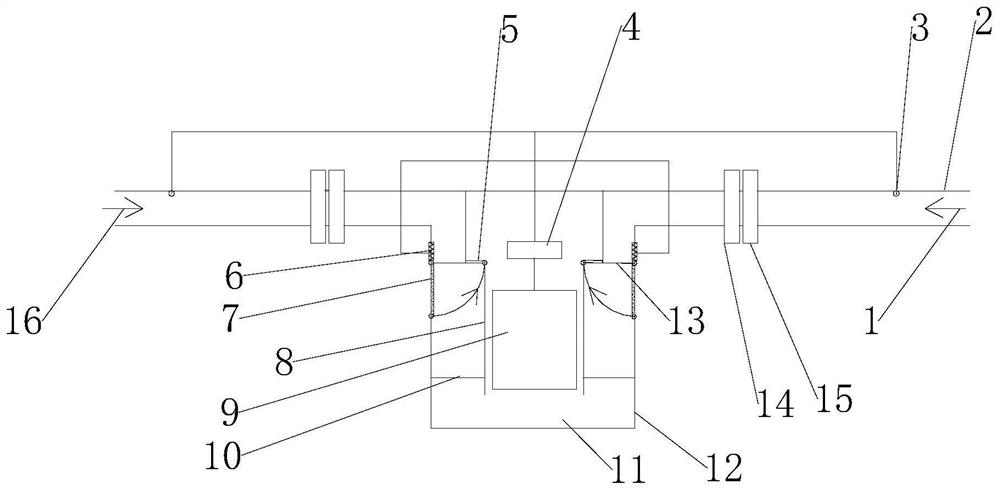

[0047] ①Working process of the flame arrester under normal working conditions:

[0048] Under normal working conditions, the gas medium in the pipeline or storage tank circulates in the pipeline 2, and enters the next device through the flame arrester channel in the direction of the arrow.

[0049]In this process, the resistance suffered by the gas medium in the circulation process is the resistance loss caused by the friction resistance in the pipeline, the elbow resistance and the gravity difference; compared with the conventional flame arrester, it is blocked by the multi-layer fire arresting unit, and its resistance loss is higher than that of the conventional flame arrester. greatly reduced.

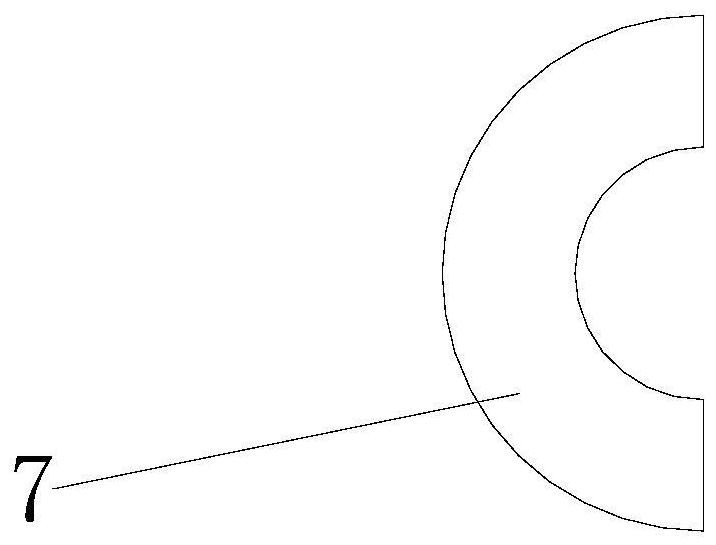

[0050] During this process, the fire retardant sheet and the like are at the position of the fire retardant sheet 7, which does not affect the normal flow of gas.

[0051] Since the pipeline flame arrester is a two-way symmetrical structure, the gas from 1 or 16 in the figure is re...

Embodiment 2

[0053] ②Working process of the flame arrester against deflagration (right side, flame 1 direction in the pipeline):

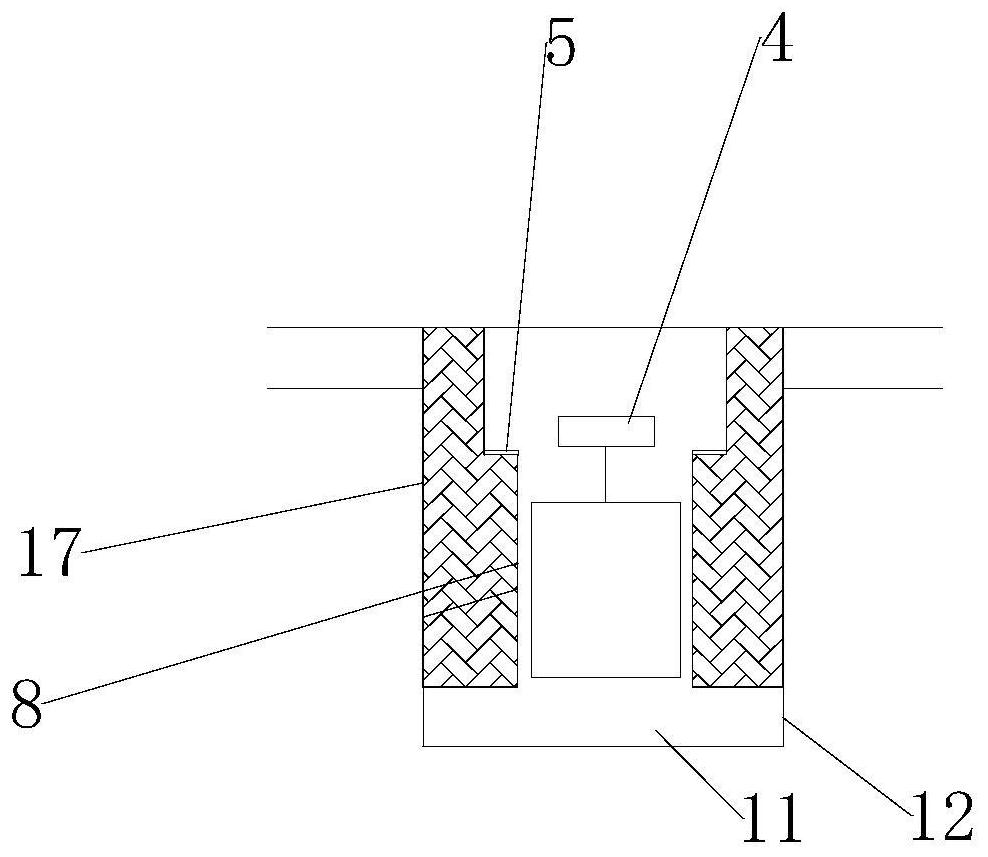

[0054] When the flame spreads in the form of deflagration in the pipeline, the flame 1 in the pipeline propagates in the pipeline 2, and after the flame sensor 3 detects the signal of the flame 1 in the pipeline, it sends the signal to the response cut-off actuator 4 in time, and the response cuts off the actuator 4 instantly Open the liquid container 9, the liquid in the liquid container 9 quickly enters the flame arrester channel 11, forming a liquid cover 12 that submerges the flame arrester channel 11, forming a "dead pipe section". At the same time, when the liquid container 9 is opened, the flame arrester The seat return auxiliary mechanism 6-1 moves, and the flame arrester 7 returns Image 6 The middle 7-1 position closes the channel, thereby preventing the flame 1 in the pipeline from propagating downstream, and playing the role of fire resistance.

[...

Embodiment 3

[0057] ③Working process of the flame arrester deflagration resistance (left side, flame 16 direction in the pipeline):

[0058] When the flame spreads in the pipeline in the form of deflagration, the flame 16 in the pipeline propagates in the pipeline 2, and after the flame sensor 3 detects the signal of the flame 1 in the pipeline, it sends the signal to the response cut-off actuator 4 in time, and the response cuts off the actuator 4 instantly Open the liquid container 9, the liquid in the liquid container 9 quickly enters the flame arrester channel 11, forming a liquid cover 12 that submerges the flame arrester channel 11, forming a "dead pipe section". At the same time, when the liquid container 9 is opened, the flame arrester The auxiliary mechanism 6-2 moves back to the seat, and the fire retardant piece 7 returns Figure 7 The middle 7-2 position closes the passage, thereby preventing the flame 16 in the pipeline from propagating downstream, and playing the role of fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com