Low-density cement slurry

A cement slurry, low-density technology, applied in the field of cement slurry, can solve the problems of easily broken float beads, unable to meet the pressure requirements of deep wells, etc., and achieve the effect of improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

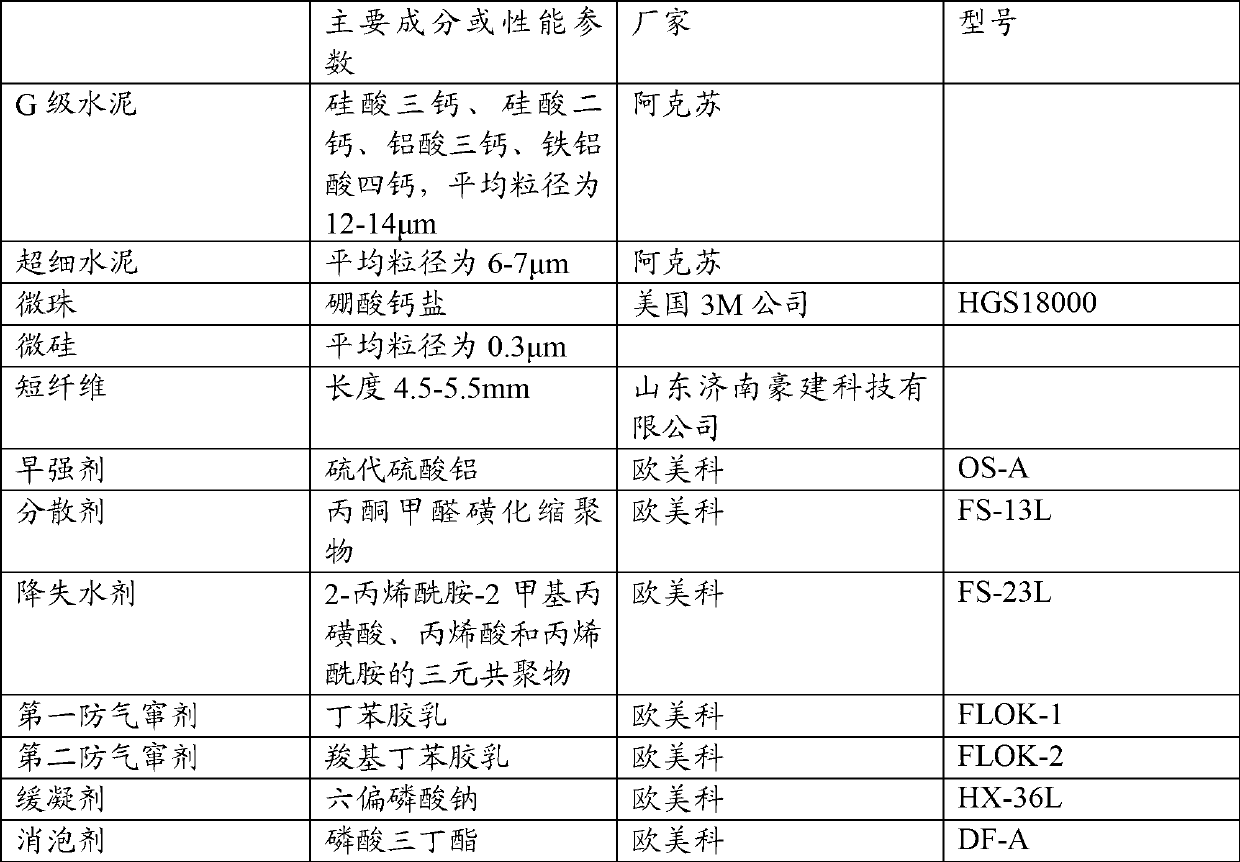

[0045] Mix 100g of G-grade cement, 15g of ultra-fine cement, 40g of micro-beads, and 8g of micro-silicon, then add 99g of water (water-solid ratio 61%) and stir evenly to make a slurry mixture, and then add a length of 5mm per liter of slurry mixture 0.15 g of polypropylene fiber to obtain cement slurry.

Embodiment 2-10

[0047] Embodiment 2-10 adopts substantially the same method as Embodiment 1, the difference lies in Table 2.

[0048] Table 2

[0049]

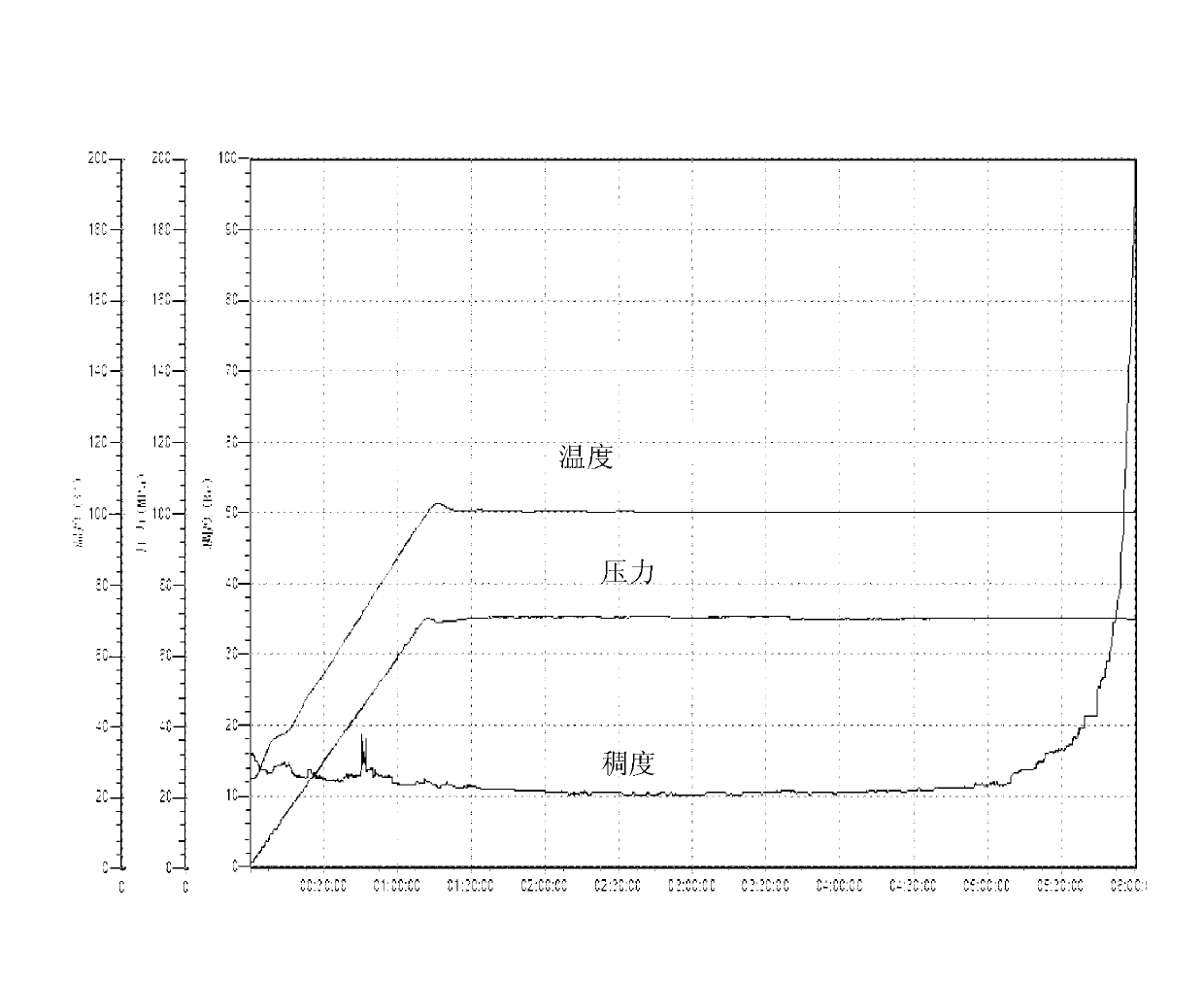

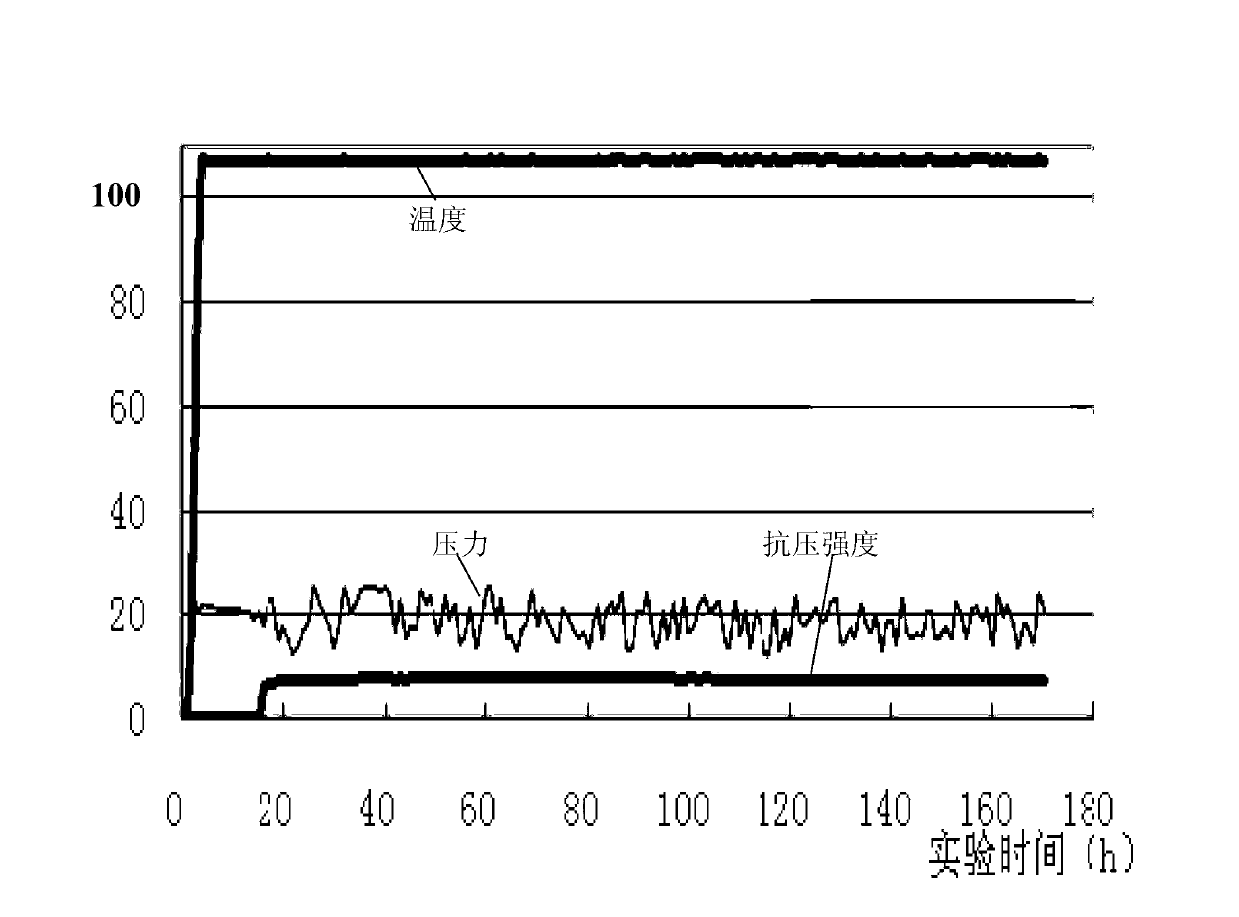

[0050] Performance Testing

[0051] The measuring devices and measuring methods used in the product analysis in the following examples all refer to GB / T19139-2003 Oil Well Cement Test Method.

[0052] Shown in Table 3 is the rheological performance table of the cement slurry obtained in Examples 1-10.

[0053] table 3

[0054]

[0055] The above shear stress readings are read with the rotation speed per minute, which are the shear stresses at 600 rpm, 300 rpm, 200 rpm, 100 rpm, 6 rpm, and 3 rpm. stress.

[0056] The n value in the above table refers to the fluidity index, which refers to the index of the shear rate of the fluid in the rheological mode, and reflects the rheology of the cement slurry. The n values of the cement slurries obtained in Examples 1-10 are all above 0.8, indicating that the cement slurries obtained in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com