Tail pipe well drilling and well completion technique

A liner and drilling technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling and other directions, can solve the problems of difficult to guarantee the cementing quality, short drilling length, long drilling length, etc., and achieve excellent cementing quality, Reliable drilling with fewer tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

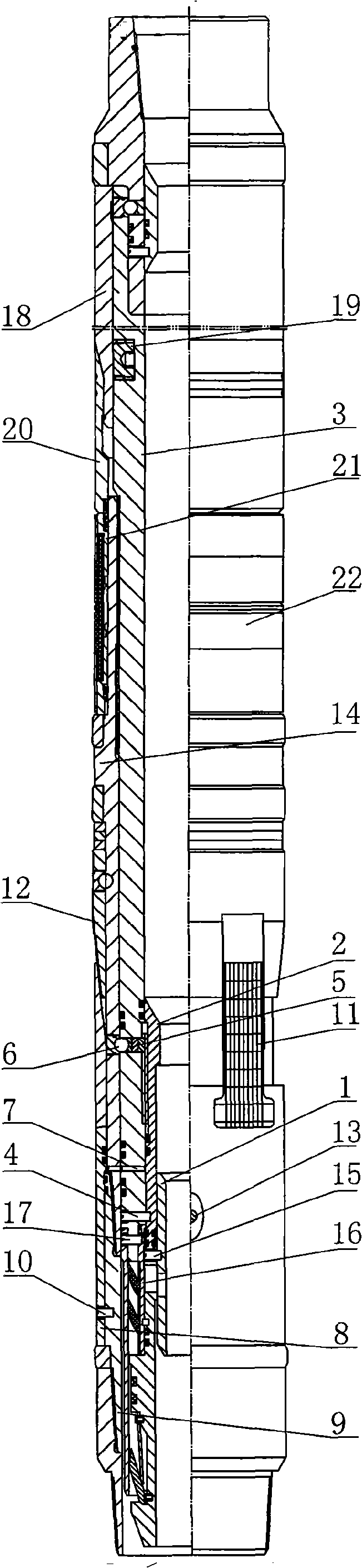

[0019] The present invention will be further described below in conjunction with accompanying drawing:

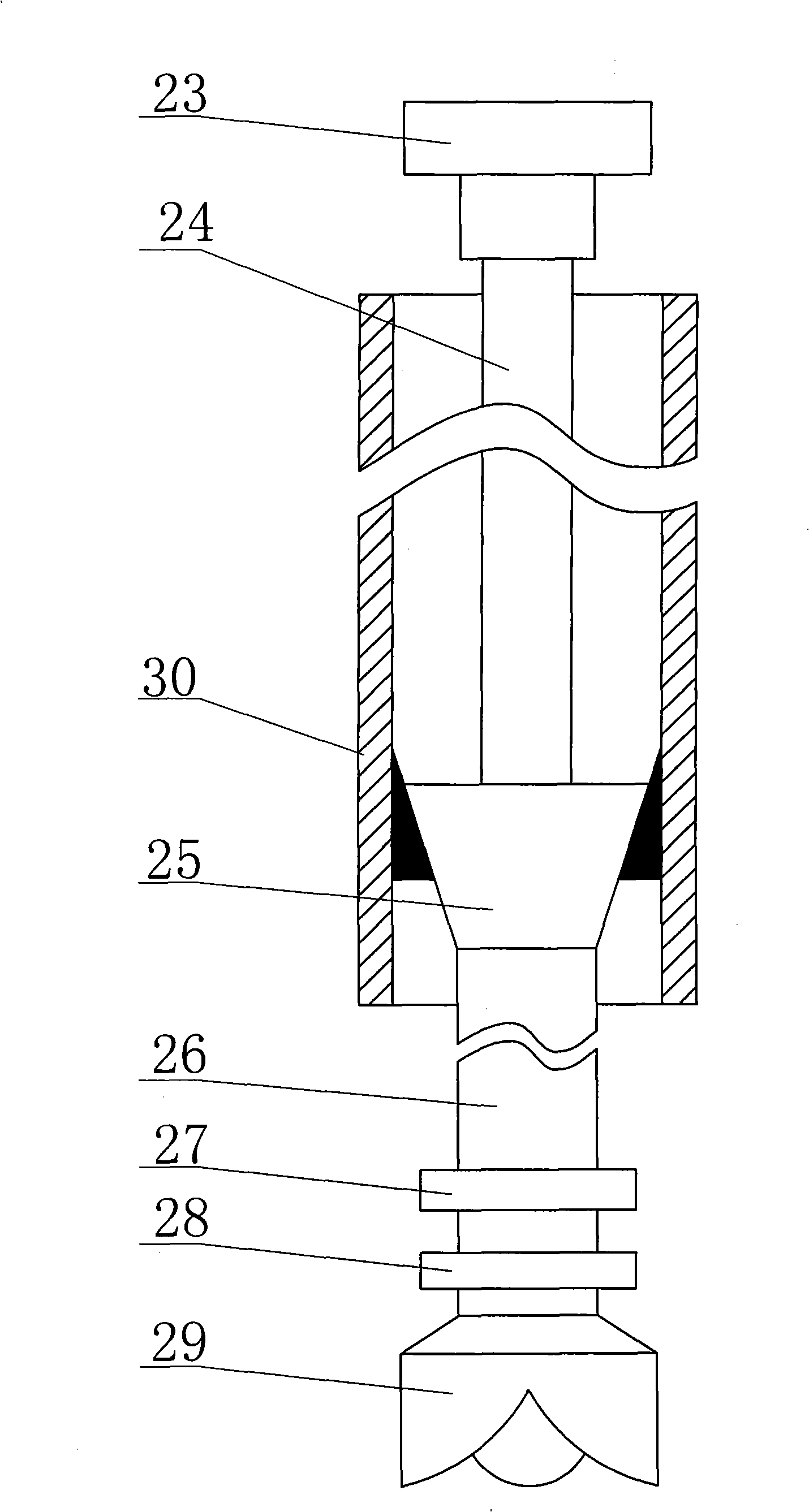

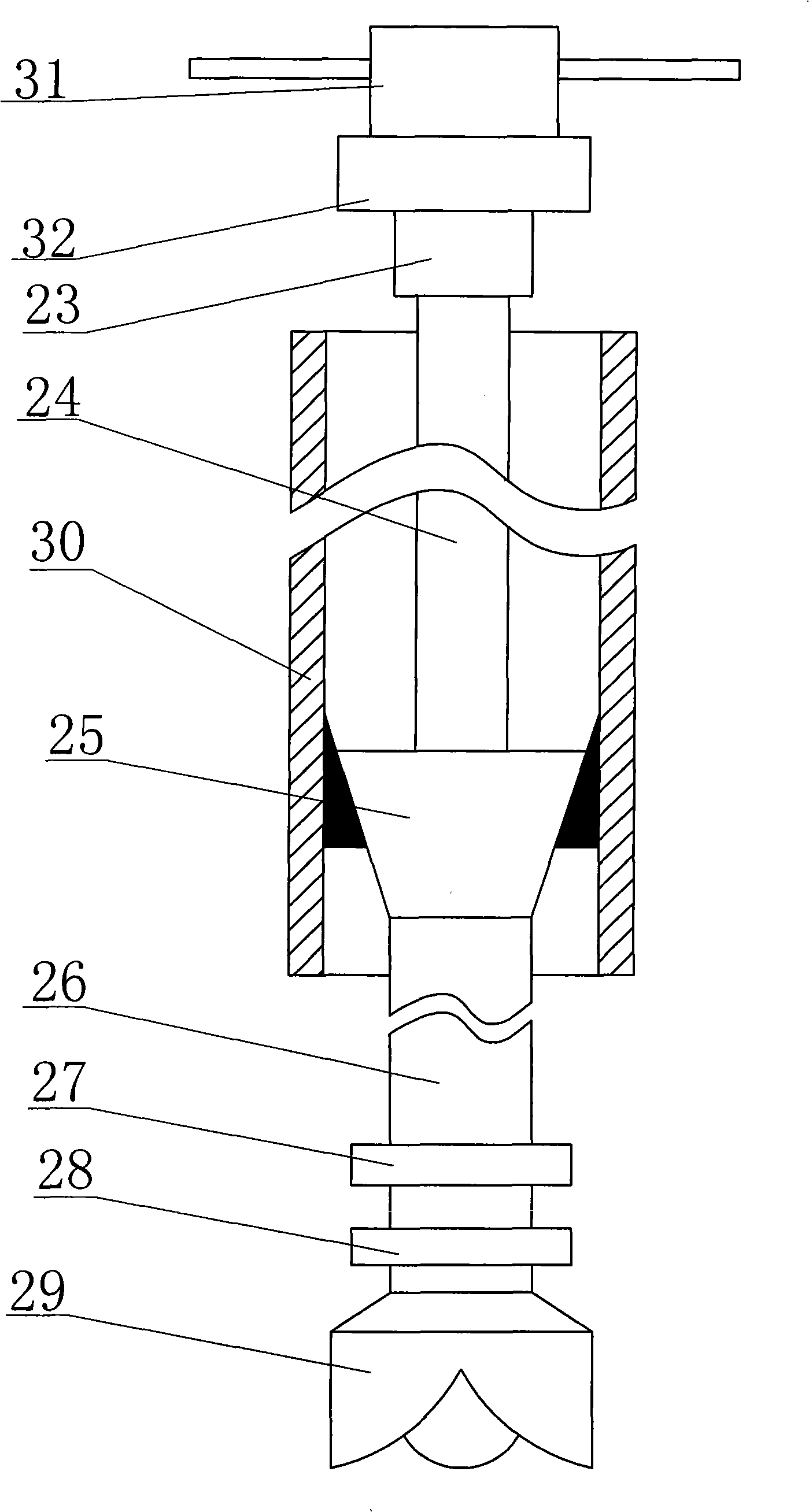

[0020] Depend on figure 1 combine figure 2 , image 3 As shown, the liner drilling and completion process is after technical casing cementing;

[0021] (1), liner drill string connection. The main function of this operation is to form the liner drill string. It includes kelly 23, drill pipe 24, rotary liner hanger 25 for drilling and completion respectively, liner 26, flower basket rubber plug seat 27, floating hoop 28, and drill bit 29, which are sequentially connected by threads, The rotary table drives the kelly 23 for drilling and cementing, and the rotary liner hanger 25 for drilling and completion controls the connection and release of the drill pipe 24 and the liner 26 .

[0022] (2) Liner drilling. The main function of this operation is to drill smoothly with the liner drill string. Drilling is carried out by adopting the gas used in the existing ordinary dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com