Automatic packaging roll film and preparation method thereof

An automatic, film-rolling technology, applied in chemical instruments and methods, packaging, wrapping paper, etc., can solve the problems of automatic packaging failure, shutdown, film jamming, etc., to improve the quality of sealing and bonding, improve efficiency, and save processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

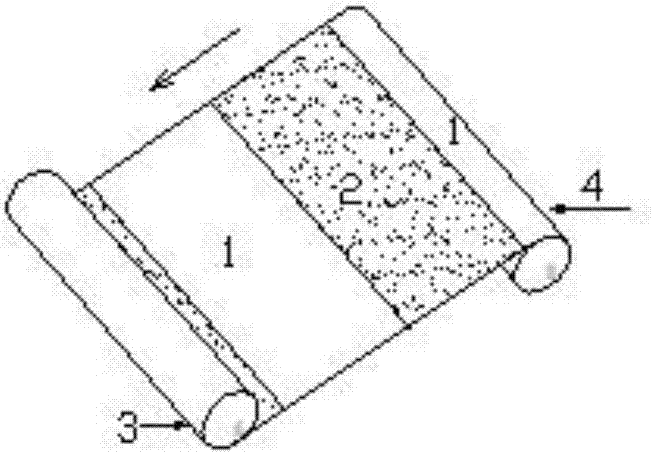

[0027] Such as figure 1 As shown, a 2700mm PE film is produced by a three-layer co-extrusion casting machine, and 8.5m of adhesive is coated on the PE roll film at an interval of 10.5m to form an adhesive film 2, and each non-adhesive film 1 and an adhesive film 2 are a packaging segment , that is, semi-finished packaging materials 4 with 10.5m non-adhesive films and 8.5m adhesive films arranged at intervals are obtained; the length and width of the packaging materials can vary according to the size and shape of the items to be packaged and the packaging purpose.

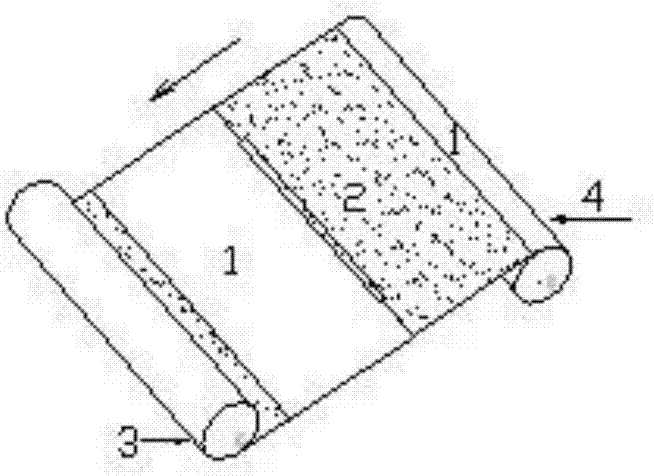

[0028] Such as figure 2 As shown, put the semi-finished packaging material 4 into the rewinder, and cut the joint between the adhesive film 2 and the non-adhesive film 1 of the adjacent packaging section;

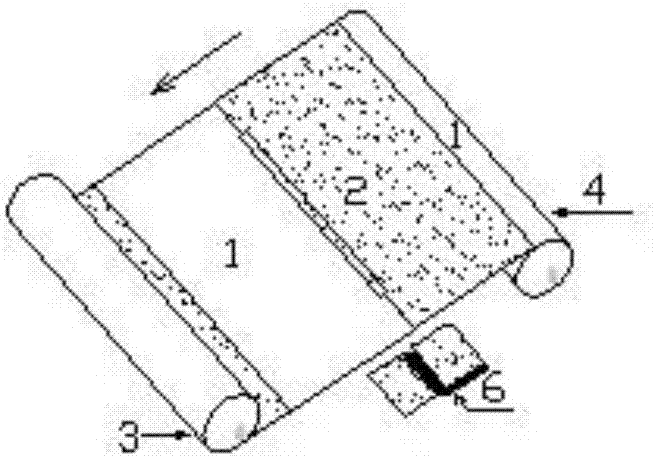

[0029] Such as image 3 As shown, a U-shaped double-sided adhesive tape 6 is bonded between the cut non-adhesive film 1 and the adhesive film 2, and the double-sided adhesive base layer 6D is bonded on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com