Lithium ion battery lead ultrasonic welding method and lead welding protection method

A technology of ultrasonic welding and lithium-ion batteries, applied in welding equipment, non-electric welding equipment, metal processing, etc., can solve the problem that the surface of tab foil is easily broken or cracked by vibration, and achieve high consistency, firm welding, The effect of the enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

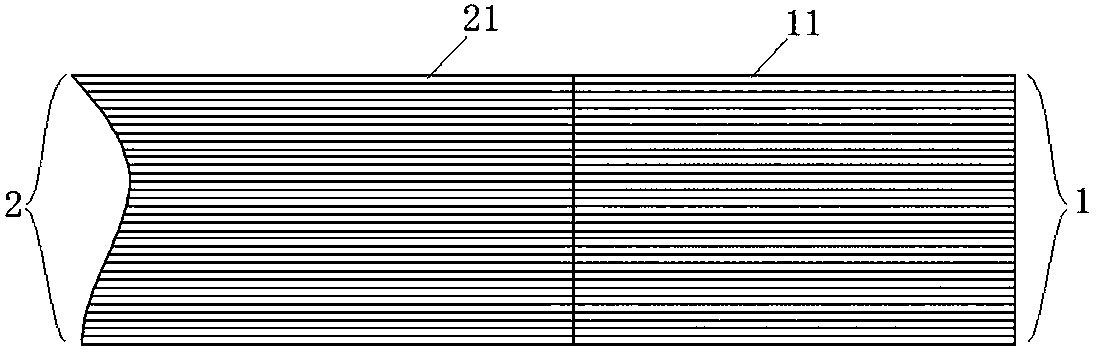

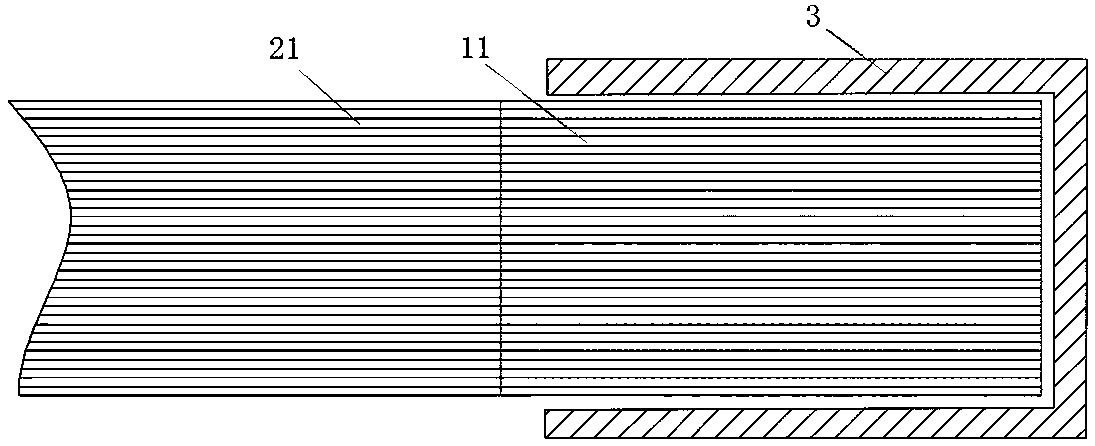

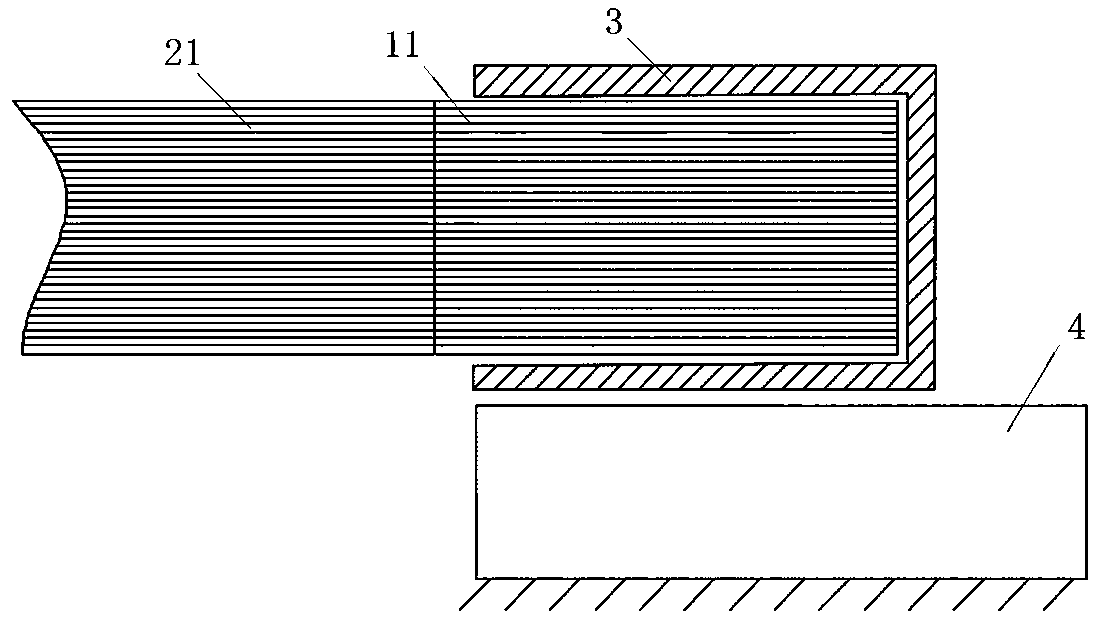

[0026] A specific embodiment of the lithium ion battery tab ultrasonic welding method of the present invention comprises the following steps: the first step, such as figure 1 As shown, the pole piece foil 21 and the tab foil 11 with a thickness of about 0.01mm are superimposed together, the pole piece foil 21 and the tab foil 11 are integrated, and the tab foil 11 is the part of the pole piece 2. For the current lead-out parts, when the pole piece foil 21 and the tab foil 11 are superimposed, ensure that they are aligned up, down, left, and right, and the edges are neat. The adjacent pole piece foils 21 are coated with lithium iron phosphate or ternary, Coatings of graphite, etc.; second step, such as figure 2 As shown, the 0.1mm thick copper foil or aluminum foil is wrapped on the stacked tab foil 11 to form a soldering protection sheet 3. The solderi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com