Real-time detection and weld quality prediction in vibration welding process

A vibration welding and quality technology, applied in welding equipment, non-electric welding equipment, structural parts, etc., can solve problems such as difficulty in producing consistent high-quality welding parts, welding parts affecting the performance of the welded system, and affecting welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

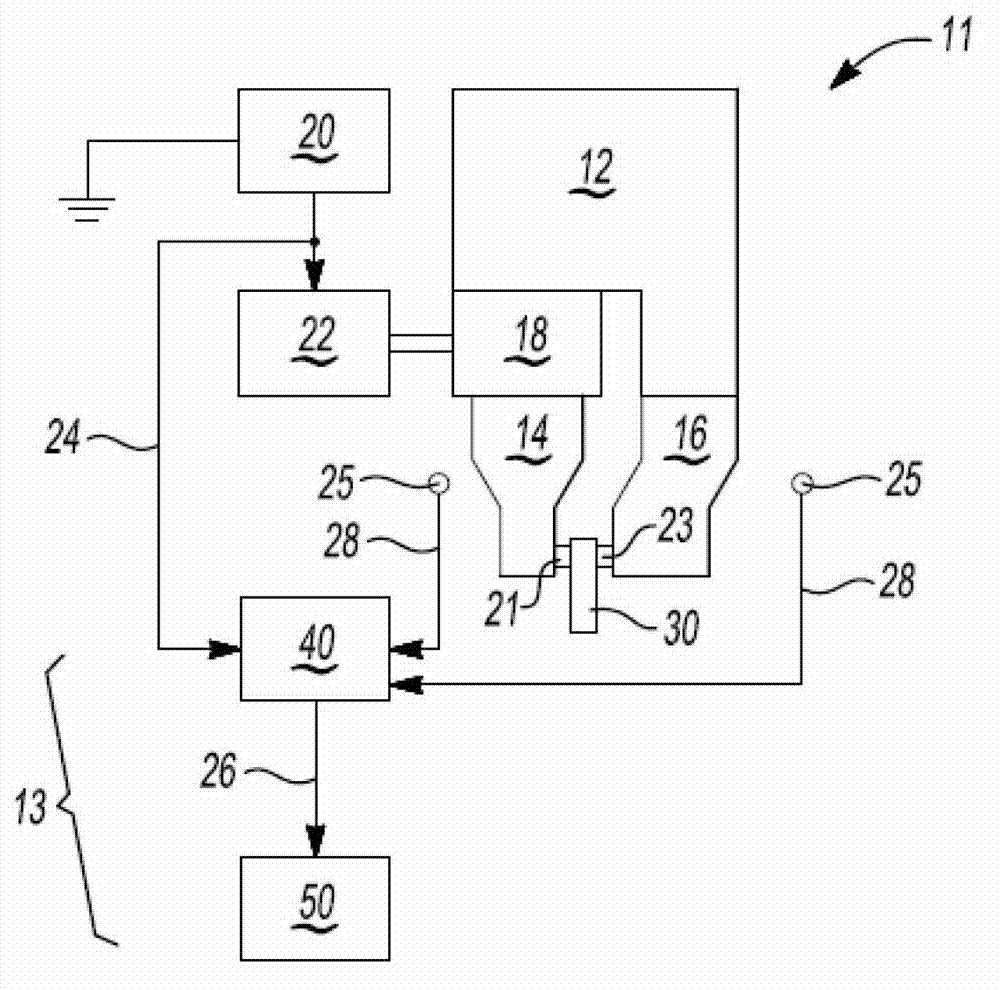

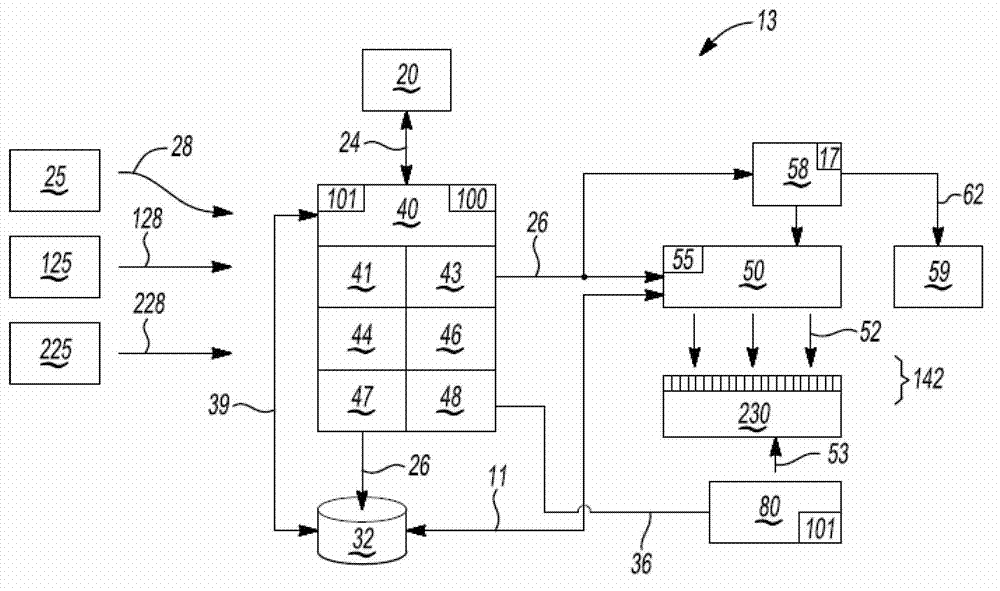

[0014] Referring to the drawings, in which like reference numerals indicate like parts in the several views, a vibration welding system 11 is schematically shown in figure 1 middle. The vibration welding system 11 includes a welding assembly 12 and a monitoring system 13 . Monitoring system 13 is in communication with welding assembly 12 . The purpose of using the monitoring system 13 is to improve production efficiency by substantially eliminating spurious conditions during the vibration welding process and by reducing direct manual or spot checks of each weld in a completed assembly.

[0015] figure 1 The illustrated welding assembly 12 includes a sonotrode / horn 4 and an anvil 16, as well as other tools and components as described below. Monitoring system 13 is configured to monitor various control signals provided by power supply / welding controller 20 and / or measured by a set of sensors 25 positioned relative to welding apparatus 12 . The monitoring system 13 predicts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com