Laser marking device with environment protection function

A laser marking and functional technology, used in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of metal dust diffusion, pollution, no dust removal device, etc., to reduce environmental noise, avoid pollution, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

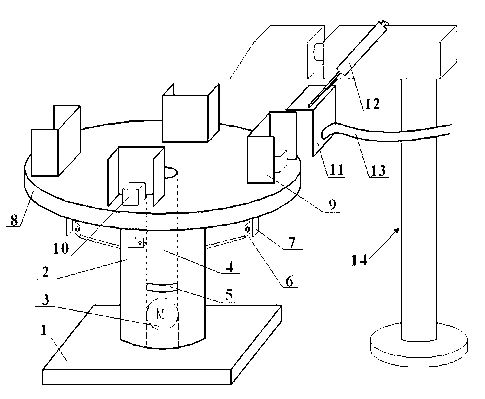

[0016] Below, a laser marking device with environmental protection function of the present invention will be described in detail in conjunction with the accompanying drawings and embodiments:

[0017] Such as figure 1 As shown, a laser marking device with environmental protection function includes a base 1, a cylindrical column 2 is fixed on the base 1, a servo motor 3 is arranged inside the column 2, and the servo motor 3 passes through a bearing 5 and a shaft 4 connect. The top of the shaft 4 is fixedly connected to the turntable 8, and there is a gap between the top of the column 2 and the turntable 8.

[0018] Four evenly distributed proximity switches 6 are arranged on the circumference of the upper outer surface of the column 2, and the positions of the four proximity switches 6 are respectively defined as station I, station II, station III, and station IV in clockwise order. .

[0019] The turntable 8 is a disc, and the upper surface of the turntable 8 is equidistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com