Method and device for treating burrs of electrode plate of lithium battery

A processing method and electrode sheet technology, applied in the direction of alkaline storage battery electrodes, etc., can solve the problems of battery short circuit, battery scrap, safety hazards, etc., and achieve the effect of eliminating the hidden danger of internal short circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

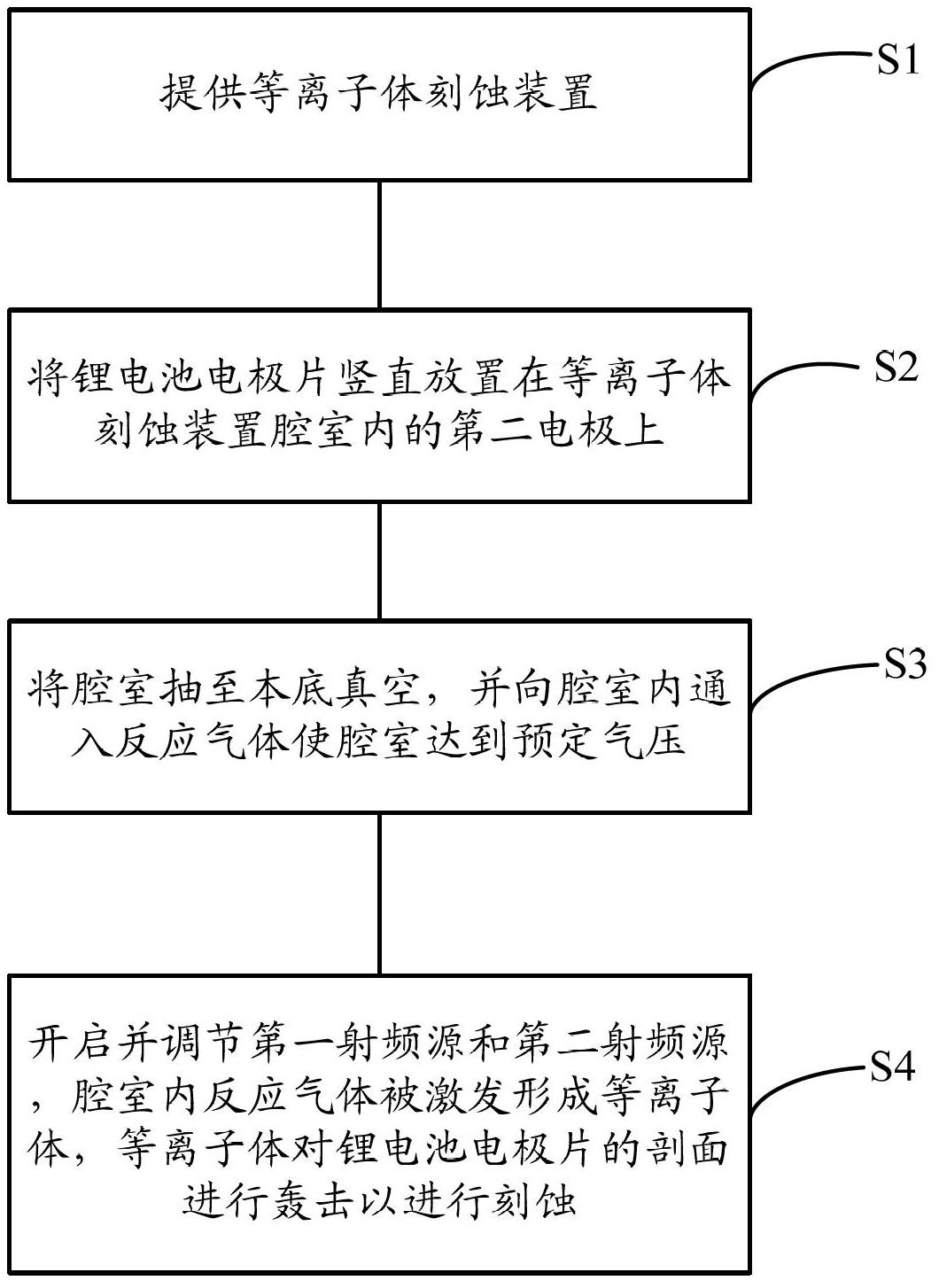

[0037] The invention discloses a method for treating burrs of lithium battery electrode sheets, the method comprising:

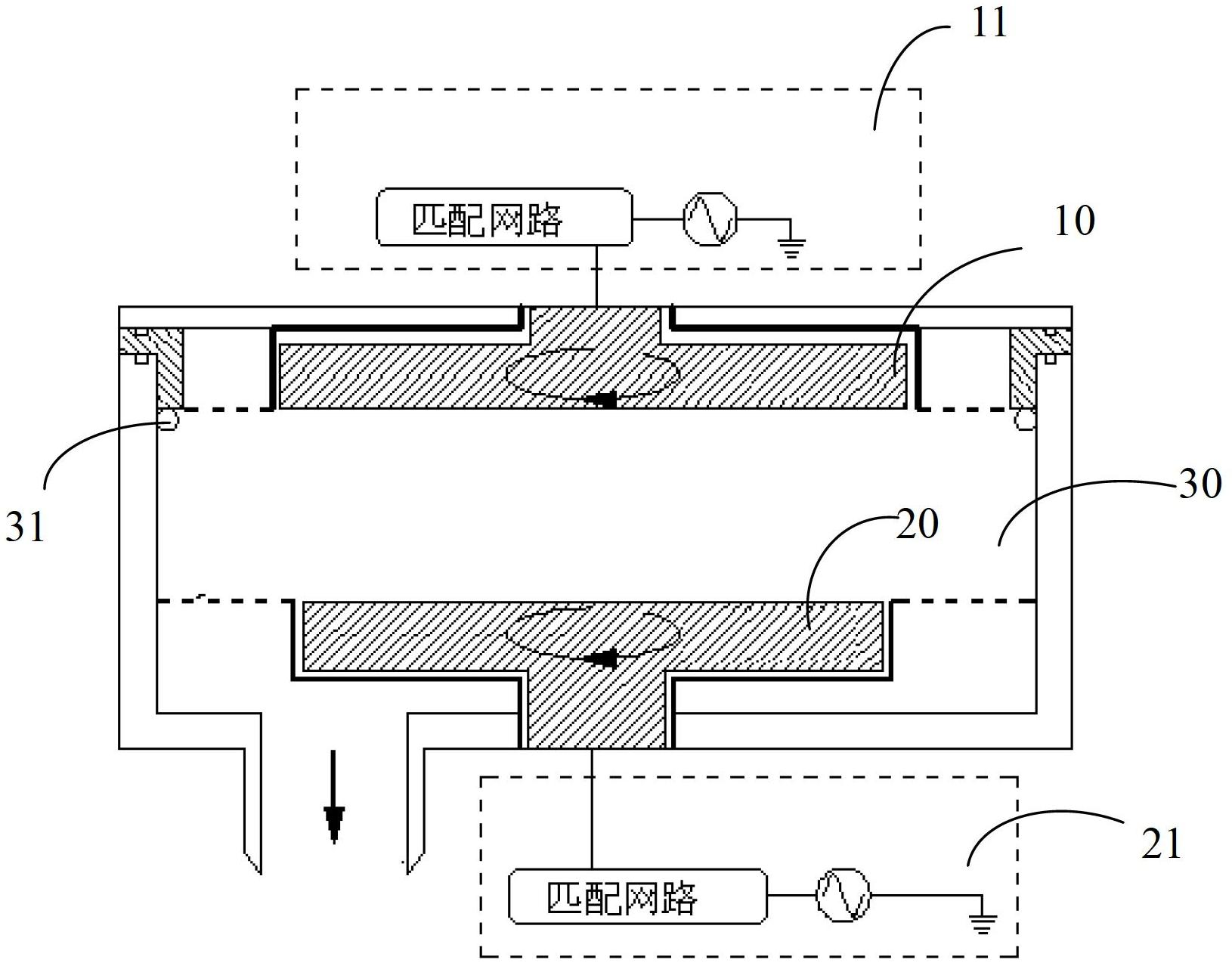

[0038] S1. Provide a plasma etching device, the plasma etching device includes a first electrode, a second electrode, and a chamber between the first electrode and the second electrode that are arranged up and down correspondingly, the first electrode is connected to a first radio frequency source, The second electrode is connected to a second radio frequency source;

[0039] S2, placing the lithium battery electrode sheet vertically on the second electrode in the chamber of the plasma etching device;

[0040] S3. Evacuate the chamber to the background vacuum, and feed the reaction gas into the chamber to make the chamber reach a predetermined air pressure;

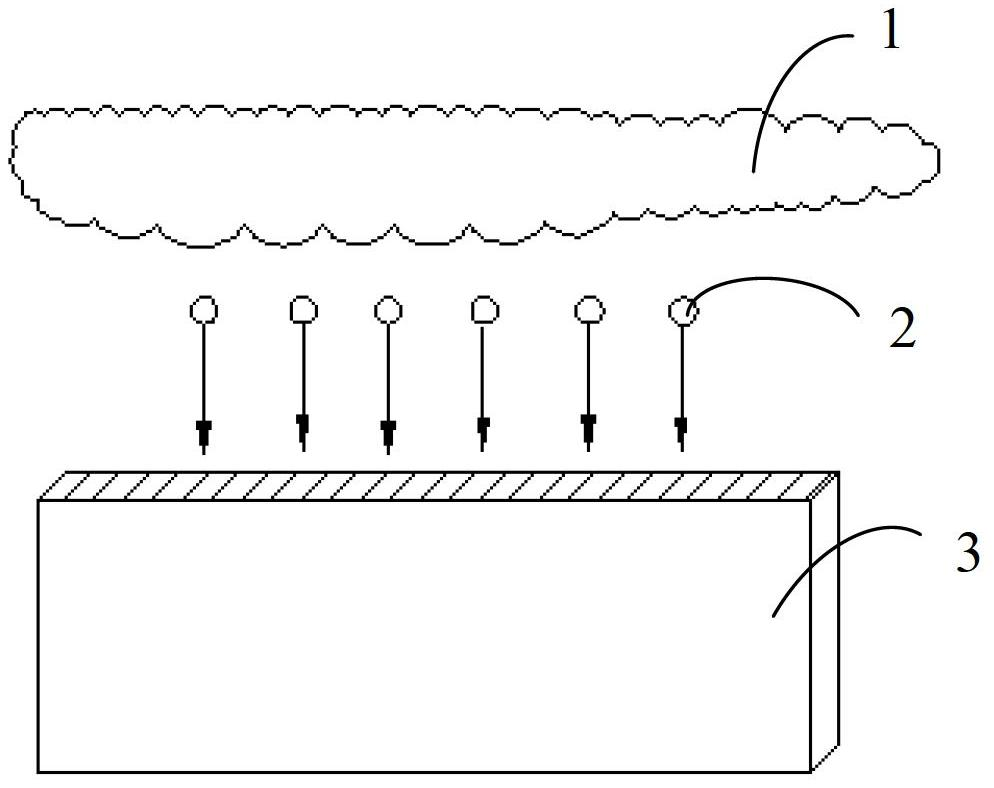

[0041] S4. Turn on and adjust the first radio frequency source and the second radio frequency source, the reaction gas in the chamber is excited to form plasma, and the plasma bombards the section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com