Coil encapsulated powder magnetic core and manufacturing method thereof

A technology of pressed powder magnetic core and pressed powder, which is applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problem that the pressed powder molded body is prone to cracks, and achieve the effect of preventing cracks or ruptures and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

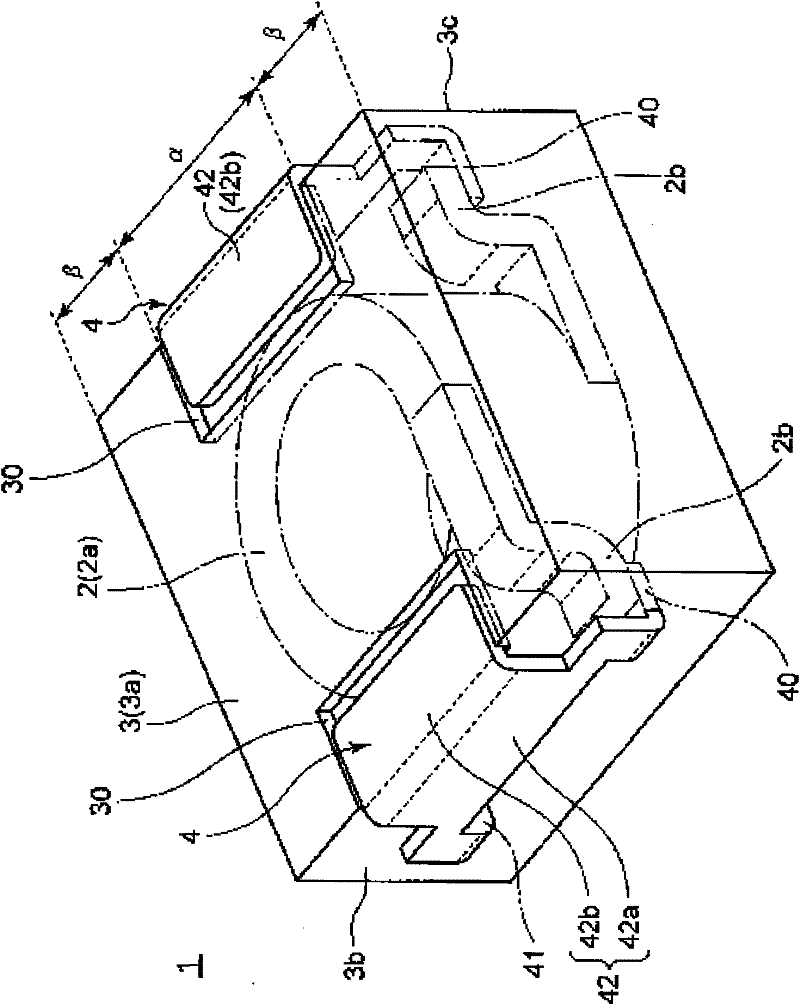

[0034] figure 1 An embodiment of a coil-enclosed powder magnetic core to which the present invention is applied is shown. The coil-encapsulated powder magnetic core 1 includes: an air-core coil 2 ; a powder compact 3 made of ferromagnetic metal powder in which the air-core coil 2 is embedded; and a terminal electrode 4 electrically connected to the air-core coil 2 .

[0035] The air-core coil 2 is formed by winding a conductive wire coated with an insulation film in a spiral shape, and has edge portions (a pair of lead-out end portions) 2b, 2b that are drawn out from the start end and end point on the upper and lower surfaces of the winding portion 2a in a direction away from each other. . The number of turns of the air-core coil 2 can be appropriately set according to the required inductance.

[0036] The powder compact 3 is formed by press-molding magnetic powder composed of ferromagnetic metal ions coated with an insulating material, and is formed in a substantially recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com