Method and apparatus for recovering solid waste material containing metal

A technology of solid waste and recycling methods, which is applied in the direction of solid waste removal, solid separation, chemical instruments and methods, etc., which can solve the problems of rough sorting process, inability to handle non-metallic powder, and high cost, and achieve controllable noise and economical considerable benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

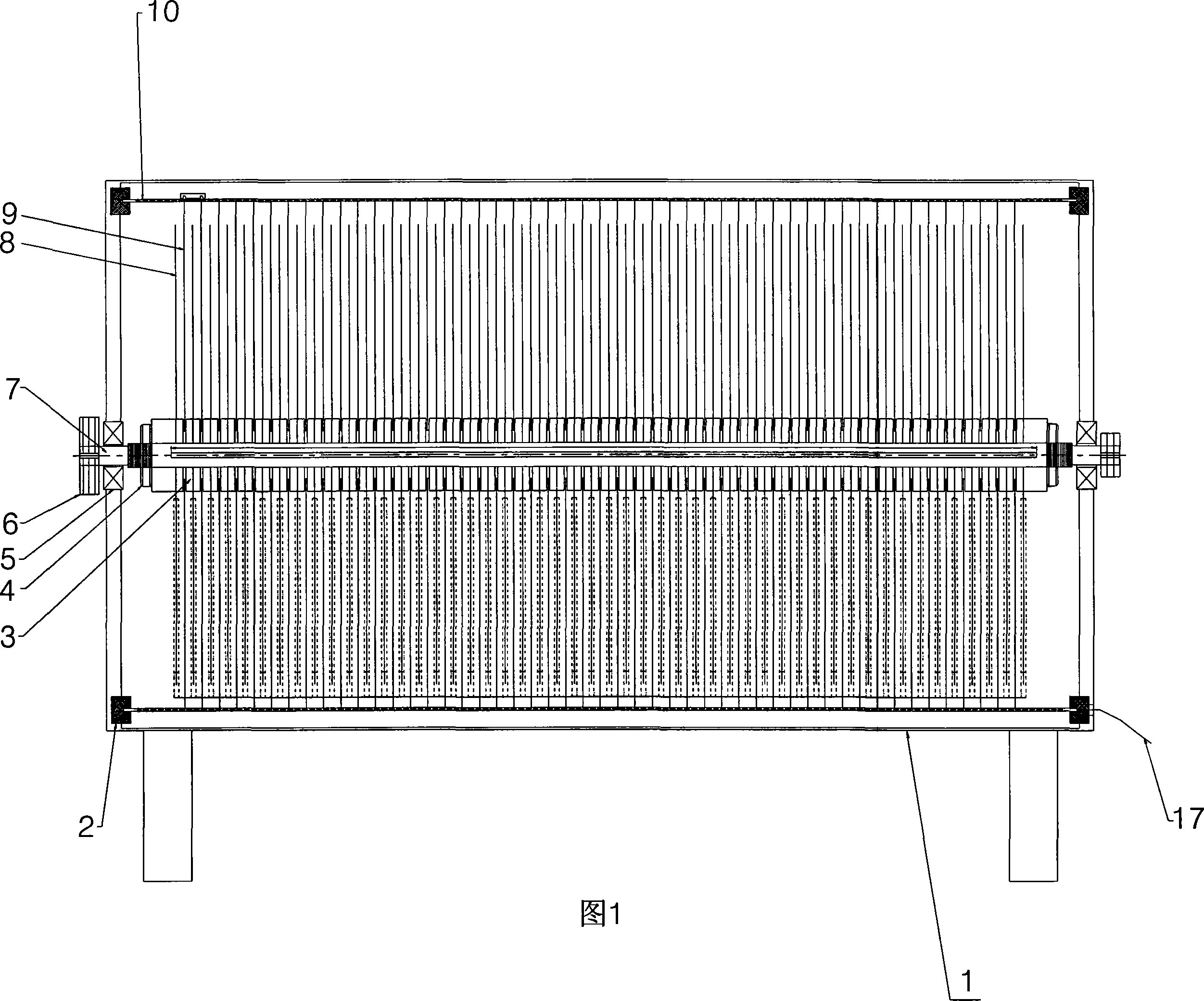

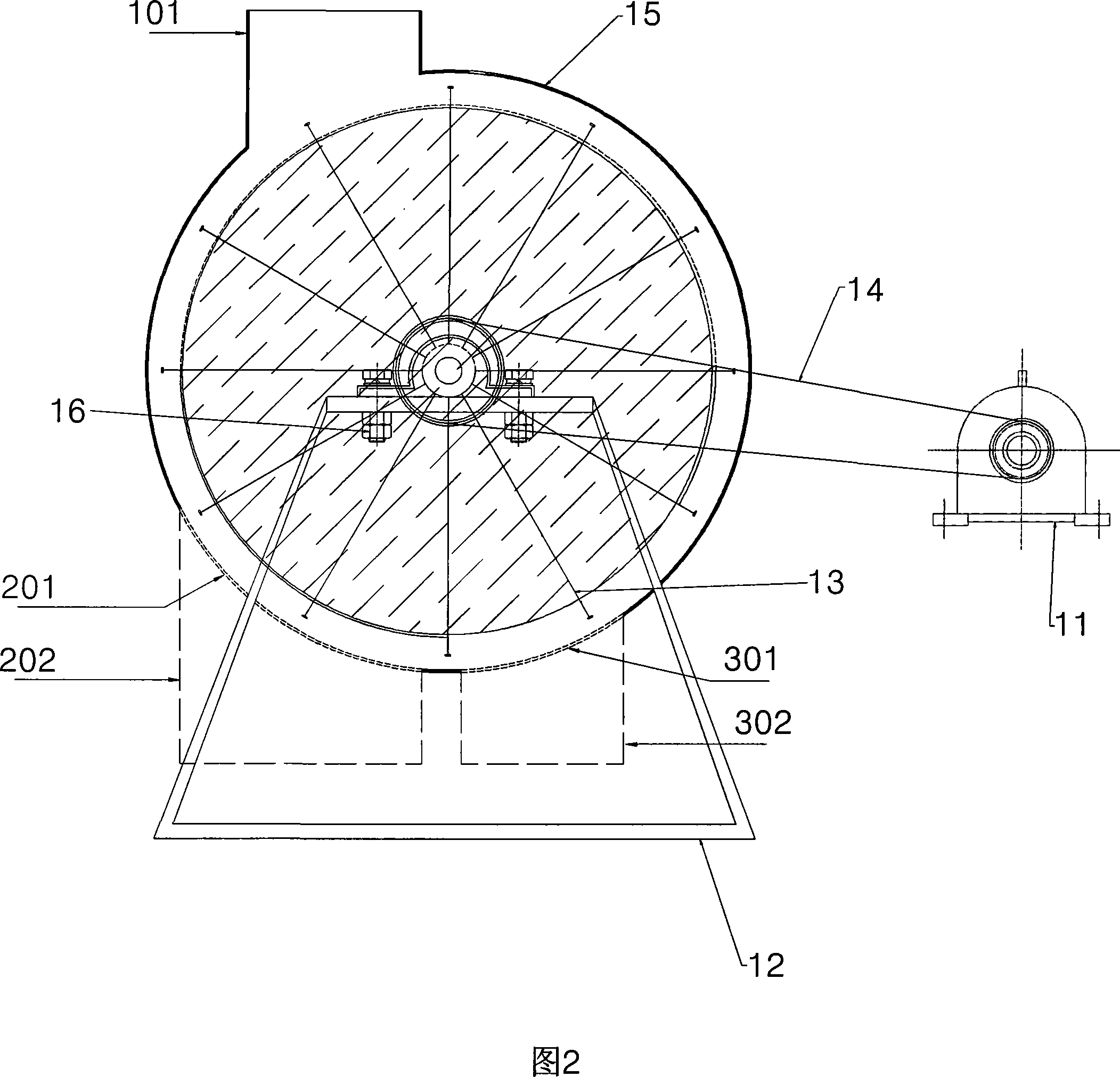

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] As shown in Figure 8, the metal-containing solid waste of the present invention is roughly broken into coarse materials with a width of less than 15 cm by a slicer, and the materials are first-level crushed by a shearing rotary crusher, and then passed through an impact rotary hammer mill. The crushing method is used for secondary crushing of the waste circuit boards. This crushing method combined with a shearing rotary crusher and an impact rotary mill can effectively crush the waste circuit boards, and at the same time, the metal and non-metallic energy in the circuit boards can be crushed. Effectively dissociate, the waste printed circuit board material without electronic components is completely dissociated below 1.2mm, while the waste printed circuit board with electronic components is completely dissociated below 0.6mm; first-level shearing with the existin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com