Roller grinding method

A grinding method and grinding technology, applied in the directions of grinding machines, abrasives, grinding/polishing equipment, etc., can solve the problems of large deformation of the rear roller 101, large temperature influence, roundness error, etc., so as to reduce the pressure on the roller deformation. , the effect of reducing the rotational vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, the present invention will be described based on preferred embodiments with reference to the drawings. In addition, the dimensions, materials, shapes, and relative arrangements of components described in the following embodiments are not intended to limit the scope of the present invention unless otherwise specified.

[0069] (grinding device)

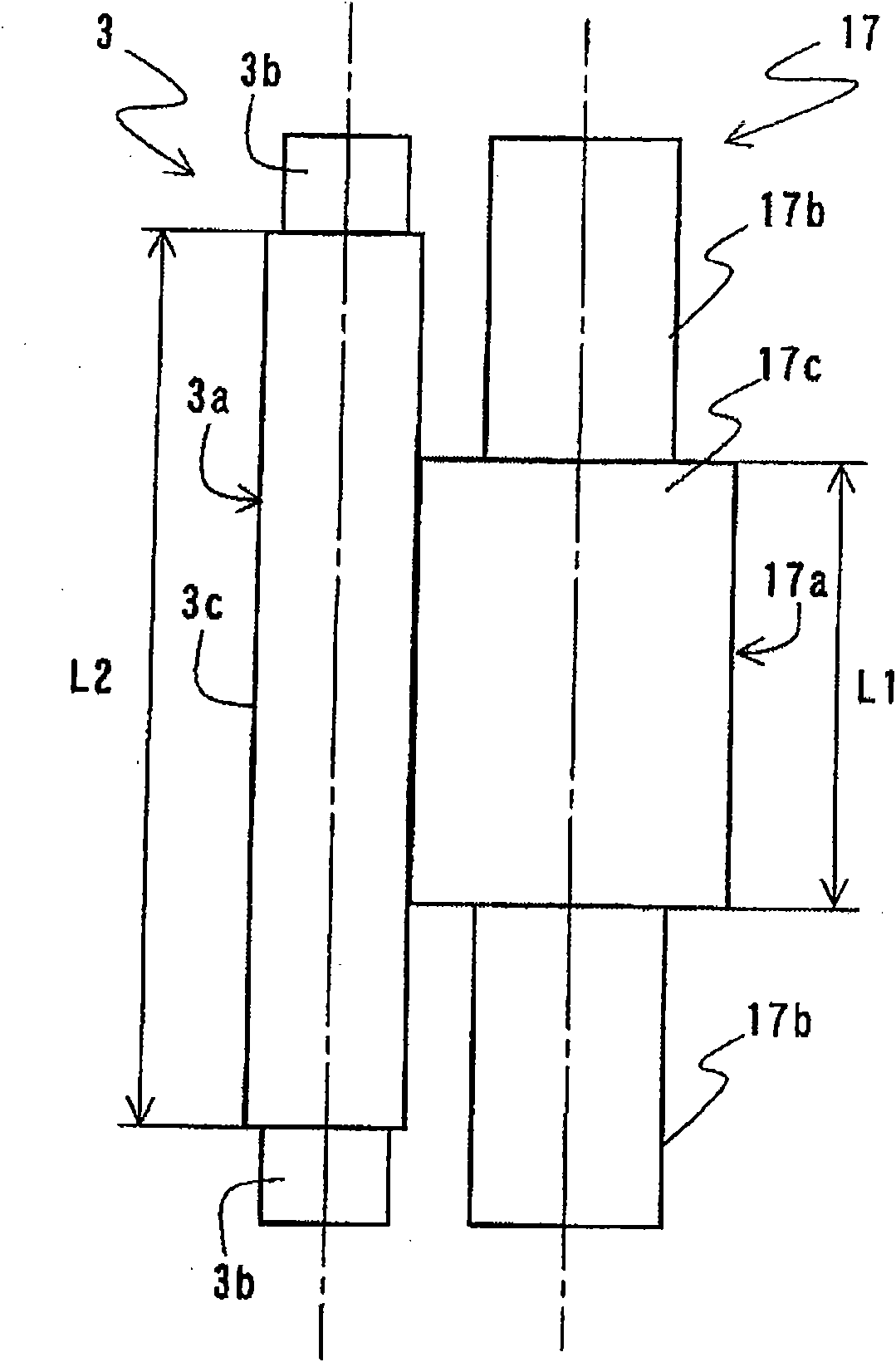

[0070] figure 1 It is a perspective view showing the grinding device 1 .

[0071] The grinding device 1 includes a grinding roll (second roll) 3 . The grinding roller 3 is provided on a base (pedestal) 5 so as to be rotatable about the axis X1. Both ends of the grinding roller 3 are supported by bearings 7 . The bearing 7 is held by a bearing housing 9 . The bearing housing 9 is fixed on the workbench 11 . Both ends of the table 11 are supported by rails 13 . The track 13 is fixed on the base platform 5 . Table 11 slides along axis Y on rail 13 by means of drive 15 . The axis Y is perpendicular to the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com