Build-up welding rod for repairing Cr3 roller and build-up welding method

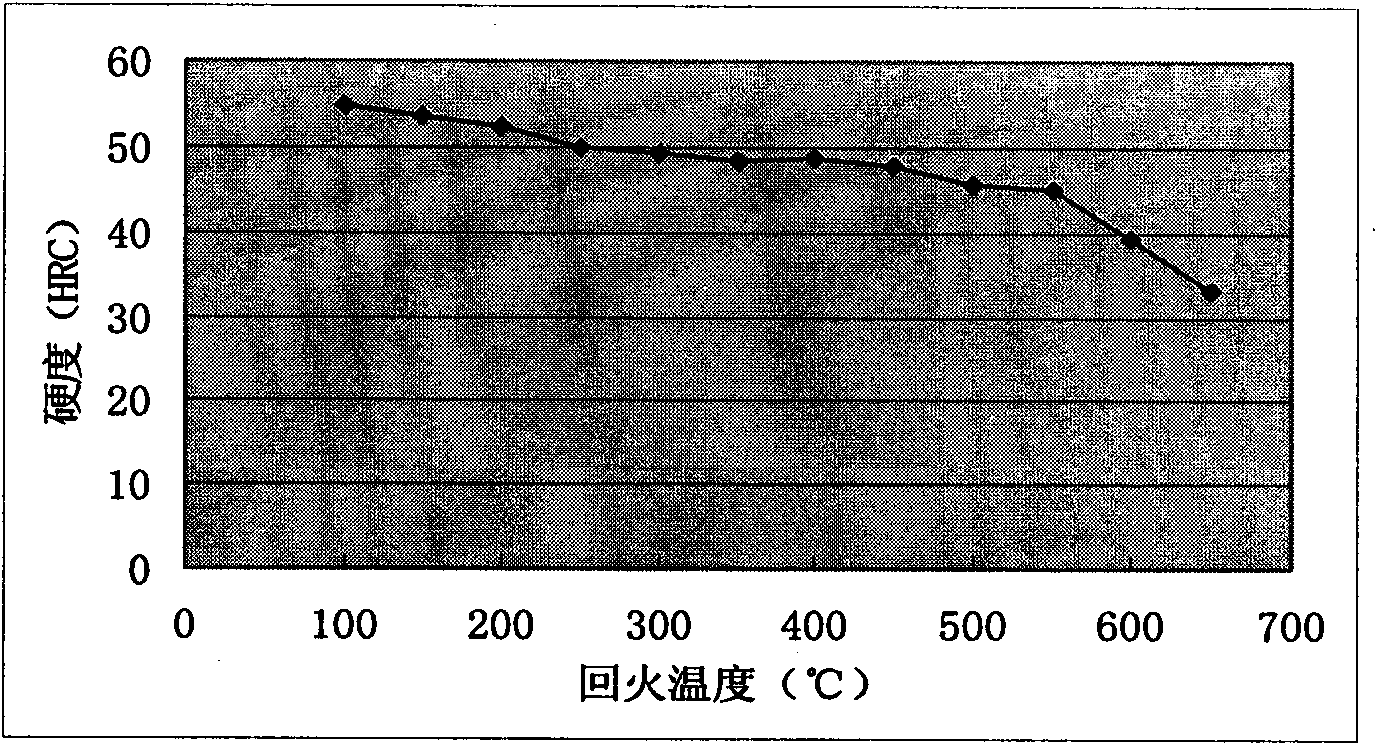

A technology for surfacing welding electrodes and rolls, which is applied in the direction of keeping the roll equipment in an effective state, welding medium, and metal rolling. It can solve the problems of low connection strength and poor tempering stability, and achieve good crack resistance, hardness and plasticity. High, good tempering stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

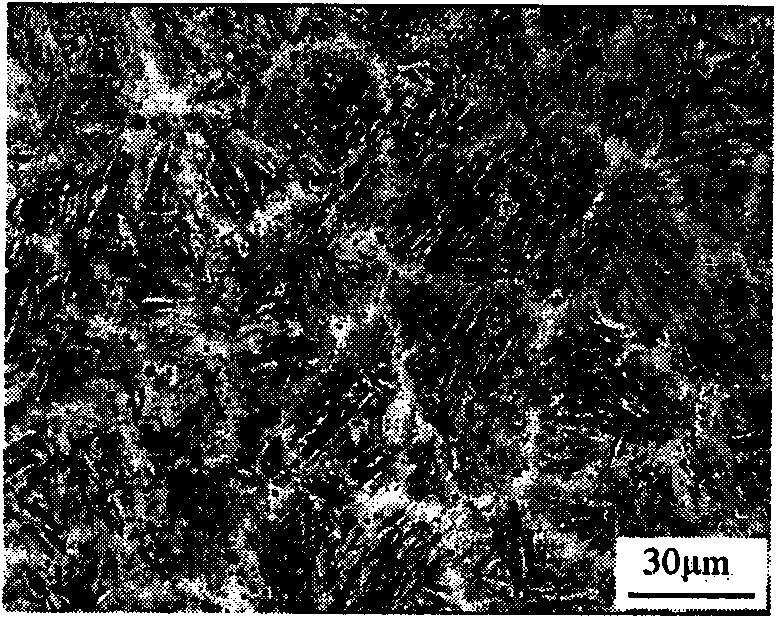

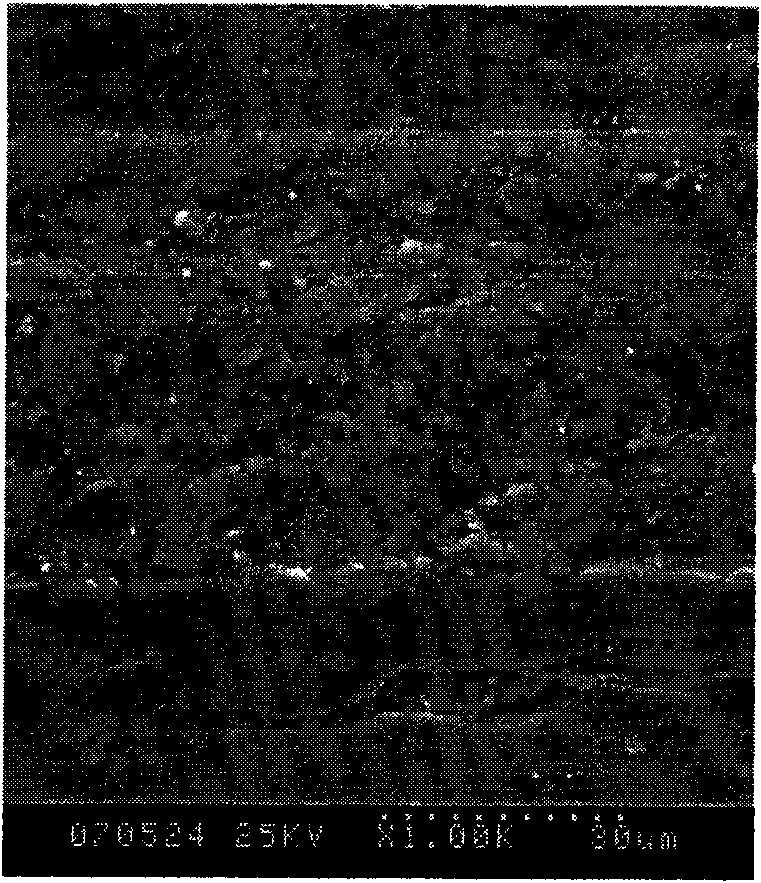

Image

Examples

Embodiment 1

[0032] A Cr3 series roll repair welding rod, including a welding core and a coating, the welding core is H08A steel, the diameter of the welding core is 3.2 mm, and the mass % components of the welding rod coating are: marble 39, fluorite 23, Low carbon ferromanganese 2.5, molybdenum ferro 2.5, high carbon ferrochrome 15, soda ash 1, rare earth alloy 2.5, titanium dioxide 6, graphite 1, ferrosilicon 45, silicon dioxide 5.5.

[0033] The process of welding and repairing the Cr3 roll by adopting the surfacing electrode in the present embodiment is as follows:

[0034] A. Pretreatment of roll defects: Grinding the cracks and defects of the roll and forming grooves on the surface of the roll;

[0035] B. Preheat treatment: Heat the roll to 350°C in a heat treatment furnace, wrap the roll surface with asbestos after it comes out of the furnace, and expose the cracks and defects on the pretreated part, that is, the polished cracks, and polish the oxide skin on the surface of the def...

Embodiment 2

[0038] A Cr3 series roll repair welding rod, including a welding core and a coating, the welding core is H08A steel, the diameter of the welding core is 4 mm, and the mass % components of the welding rod coating are: marble 36, fluorite 20, Low carbon ferromanganese 1.5, molybdenum ferro 1, high carbon ferrochrome 13, soda ash 0, rare earth alloy 1, titanium dioxide 4, graphite 0.5, ferrosilicon 45 3, silicon dioxide 4.

[0039] The process of welding and repairing the Cr3 roll by adopting the surfacing electrode in the present embodiment is as follows:

[0040] A. Pretreatment of roll defects: Grinding the cracks and defects of the roll and forming grooves on the surface of the roll;

[0041] B. Preheat treatment: heat the roll to 380°C in a heat treatment furnace, wrap the roll surface with asbestos after it comes out of the furnace, and expose the cracks and defects on the pretreated part, that is, the polished cracks, and polish the oxide skin on the surface of the defect ...

Embodiment 3

[0044] A Cr3 series roll repair welding rod, including a welding core and a coating, the welding core is H08A steel, the diameter of the welding core is 5 mm, and the mass % components of the welding rod coating are: marble 42, fluorite 26, 4 low-carbon ferromanganese, 4 ferromolybdenum, 17 high-carbon ferrochromium, 1.5 soda ash, 4 rare earth alloys, 8 titanium dioxide, 1.5 graphite, 5 ferrosilicon 45, and 7 silicon dioxide.

[0045] The process of welding and repairing the Cr3 roll by adopting the surfacing electrode in the present embodiment is as follows:

[0046] A. Pretreatment of roll defects: Grinding the cracks and defects of the roll and forming grooves on the surface of the roll;

[0047] B. Preheat treatment: Heat the roll to 330°C in a heat treatment furnace, wrap the roll surface with asbestos after it comes out of the furnace, and expose the cracks and defects on the pretreated part, that is, the polished cracks, and polish the oxide skin on the surface of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com