Vibration suppression device for rolling mill roller system

A technology of vibration suppression and roll system, which is applied in the direction of metal rolling, metal rolling, and keeping roll equipment in an effective state. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

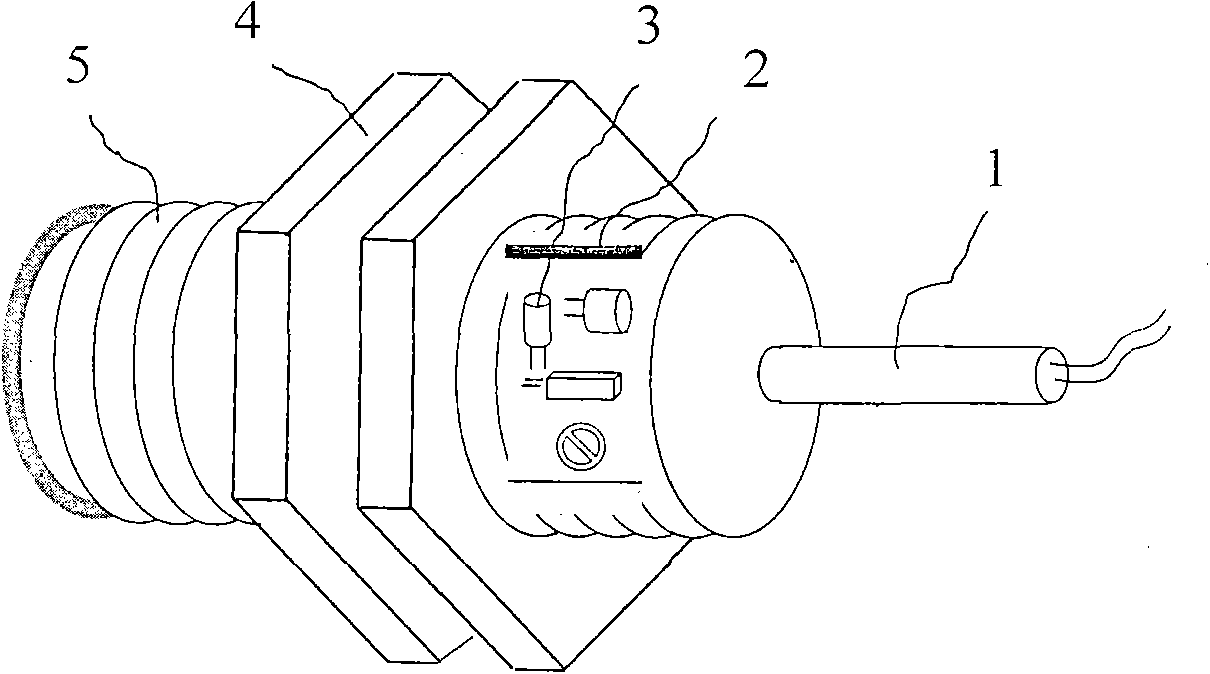

[0013] like figure 1 As shown, the vibration suppressor of the present invention is composed of a lead wire 1 , a printed circuit board 2 , an electronic device 3 , a fixing nut 4 and a housing 5 . Wherein, the lead wire 1 is led out from the output terminal of the printed circuit board 2 , and the printed circuit board 2 and the electronic device 3 are fixed on the casing 5 through the fixing nut 4 .

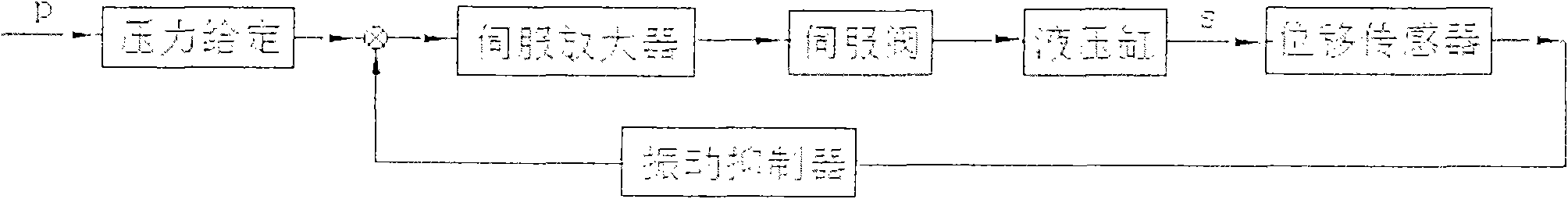

[0014] like figure 2 As shown, the present invention is composed of a vibration suppressor, a given pressure, a servo amplifier, a servo valve, a hydraulic cylinder and a displacement sensor. Among them, the vibration suppressor, pressure given setting and servo amplifier are all installed on the printed circuit board, the servo valve and hydraulic cylinder are pressed radially on the bearing seat of the roller system, and the displacement sensor detects the vibration displacement of the hydraulic cylinder and is directly fixed on the hydraulic on the tank.

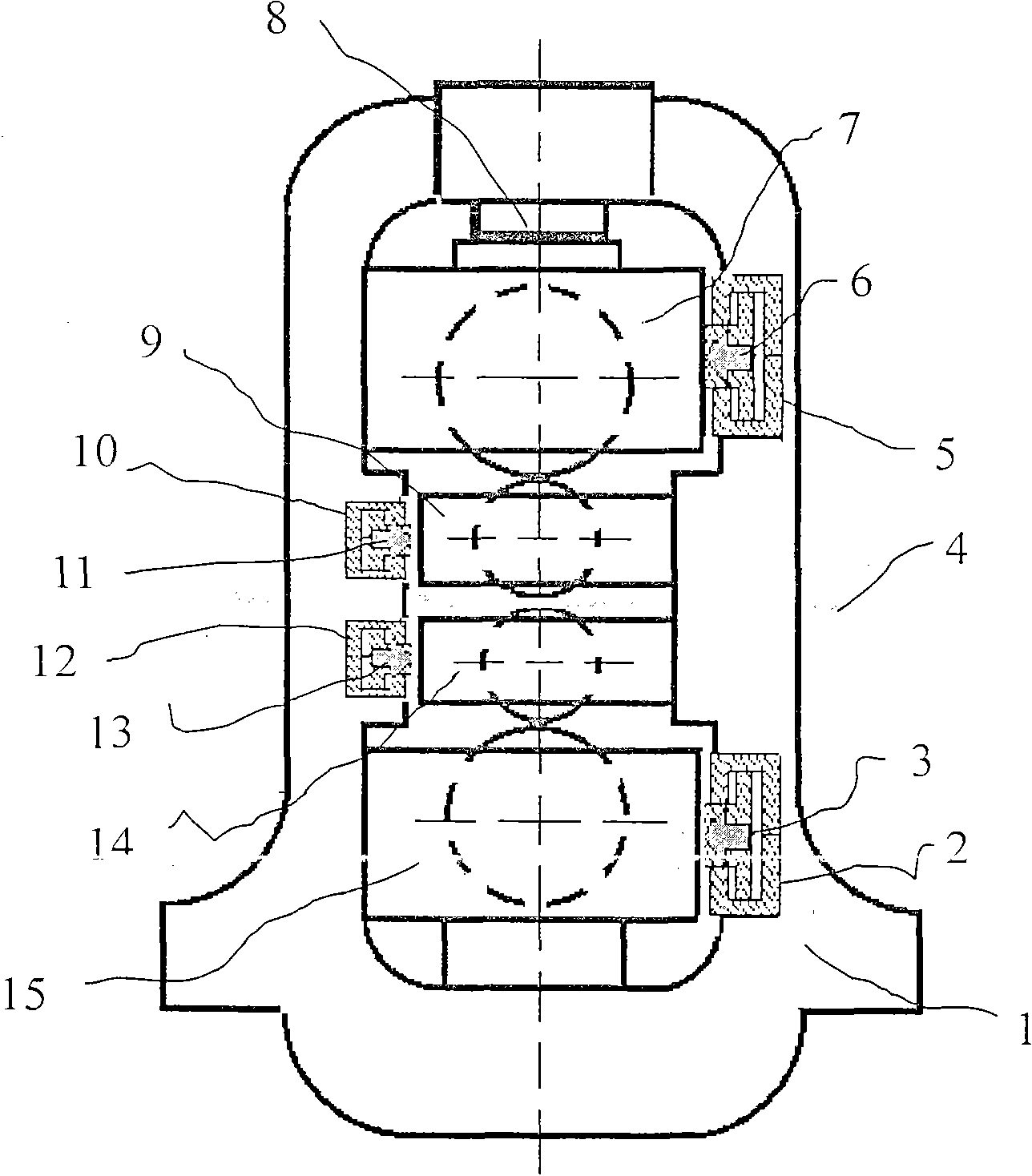

[0015] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com