Electroplastic and ultrasonic rolling pressing coupling roller on-line repairing system and method

A technology of ultrasonic rolling and electroplasticity, which is applied in the field of roll repair, can solve the problems of occupying production time, a large amount of manpower and capital investment, and long time consumption, and achieve the effect of time-consuming and less labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description will be made below in conjunction with the accompanying drawings of the embodiments.

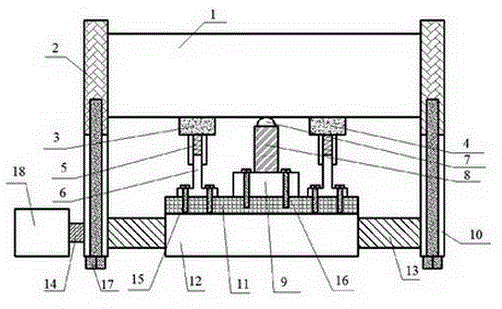

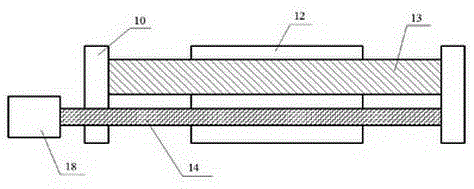

[0030] refer to figure 1 , figure 2 , a system for on-line repair of rolls coupled with electroplasticity and ultrasonic rolling, including the following parts:

[0031] A pair of supports 10 are installed on the body 2 of the rolling mill in front of the roll 1 with a support fixture 17;

[0032] Screw mandrel 14, guide rail 13 and slide block 12 driven by motor 18, screw mandrel 14, guide rail 13 are installed between the described pair of supports 10, slide block 12 is driven by screw mandrel 14, and can translate along guide rail 13;

[0033] An insulating layer 11 is provided on the slider 12, and the cylinder 9 uses a plurality of third insulating bolts 16 to pass through the installation part of the cylinder 9 and the insulating layer 11 to screw on the slider 12;

[0034] A left brush device and a right brush device are arranged on the left and right si...

PUM

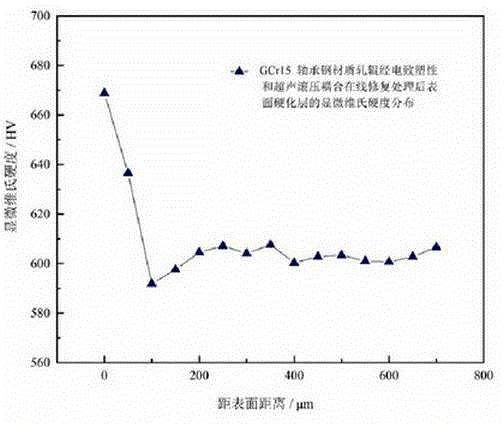

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com