Six-roller mill

A technology of six-high rolling mill and back-up roll, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc. It can solve the problem that the ability to control the shape of the plate cannot be met, and the bending force has a great influence on the eccentricity of the roll bearing. , It is not easy to overcome the problems of roll buffer force, etc., so as to achieve the effect of enhancing the shape control ability, fast roll change, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

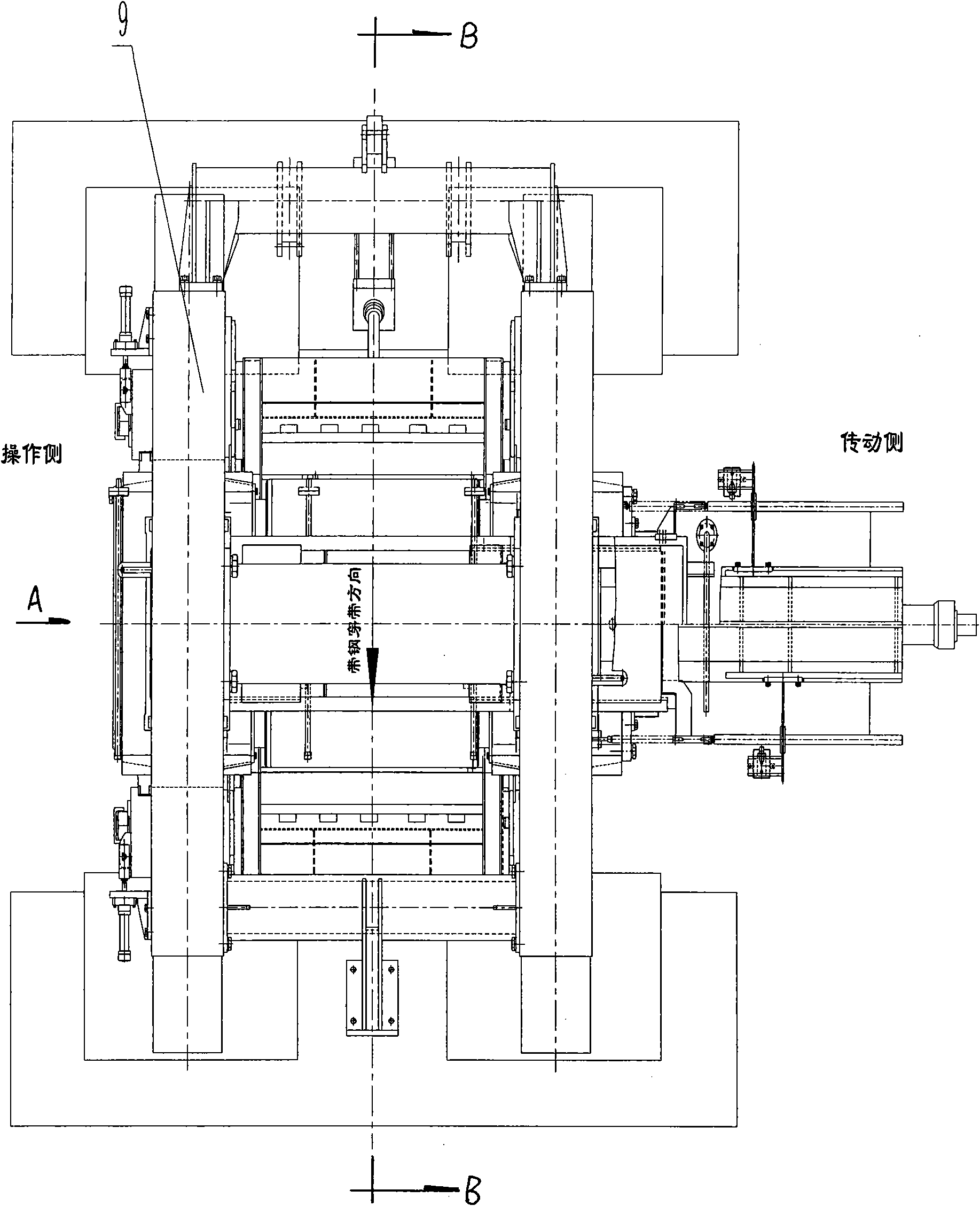

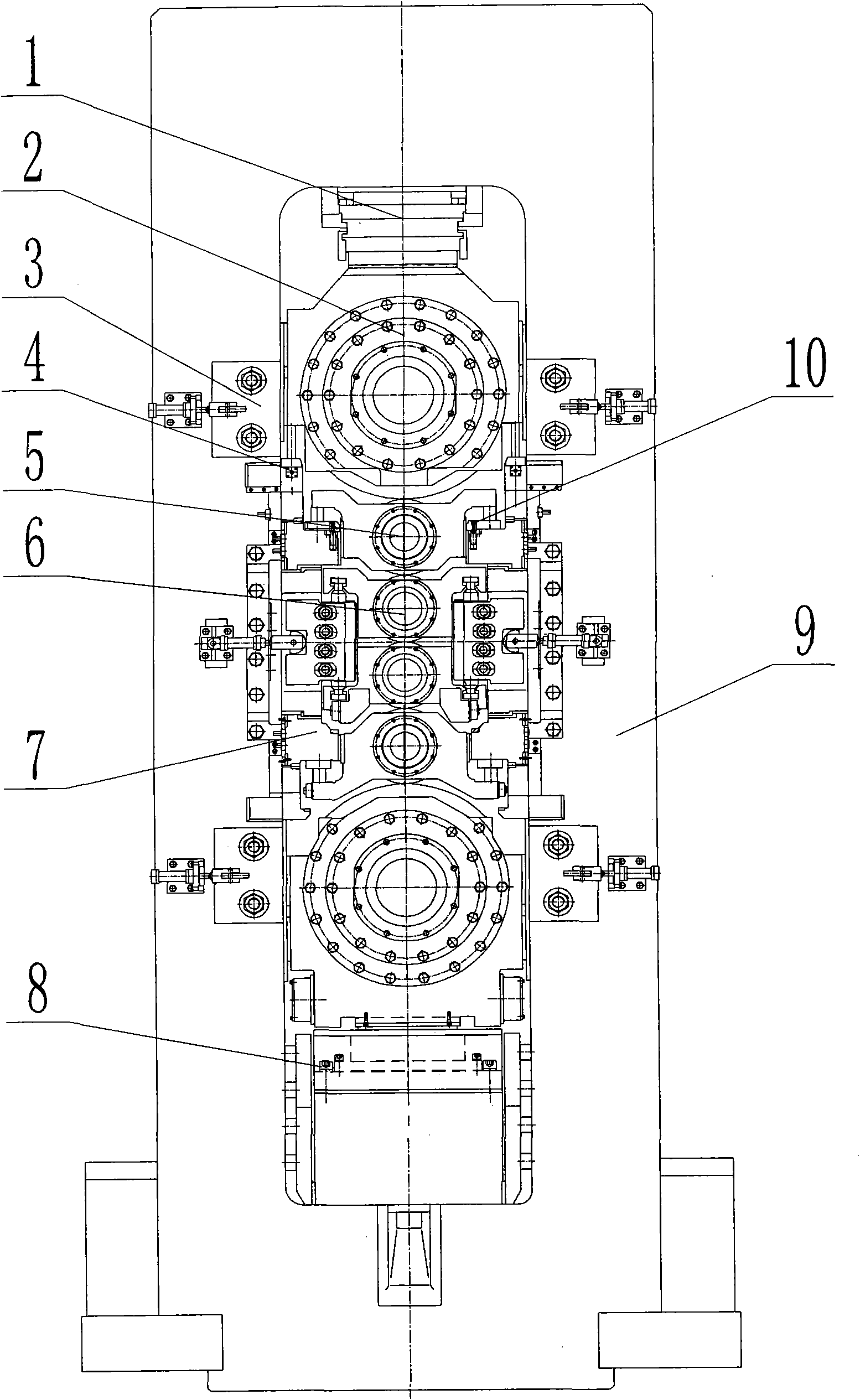

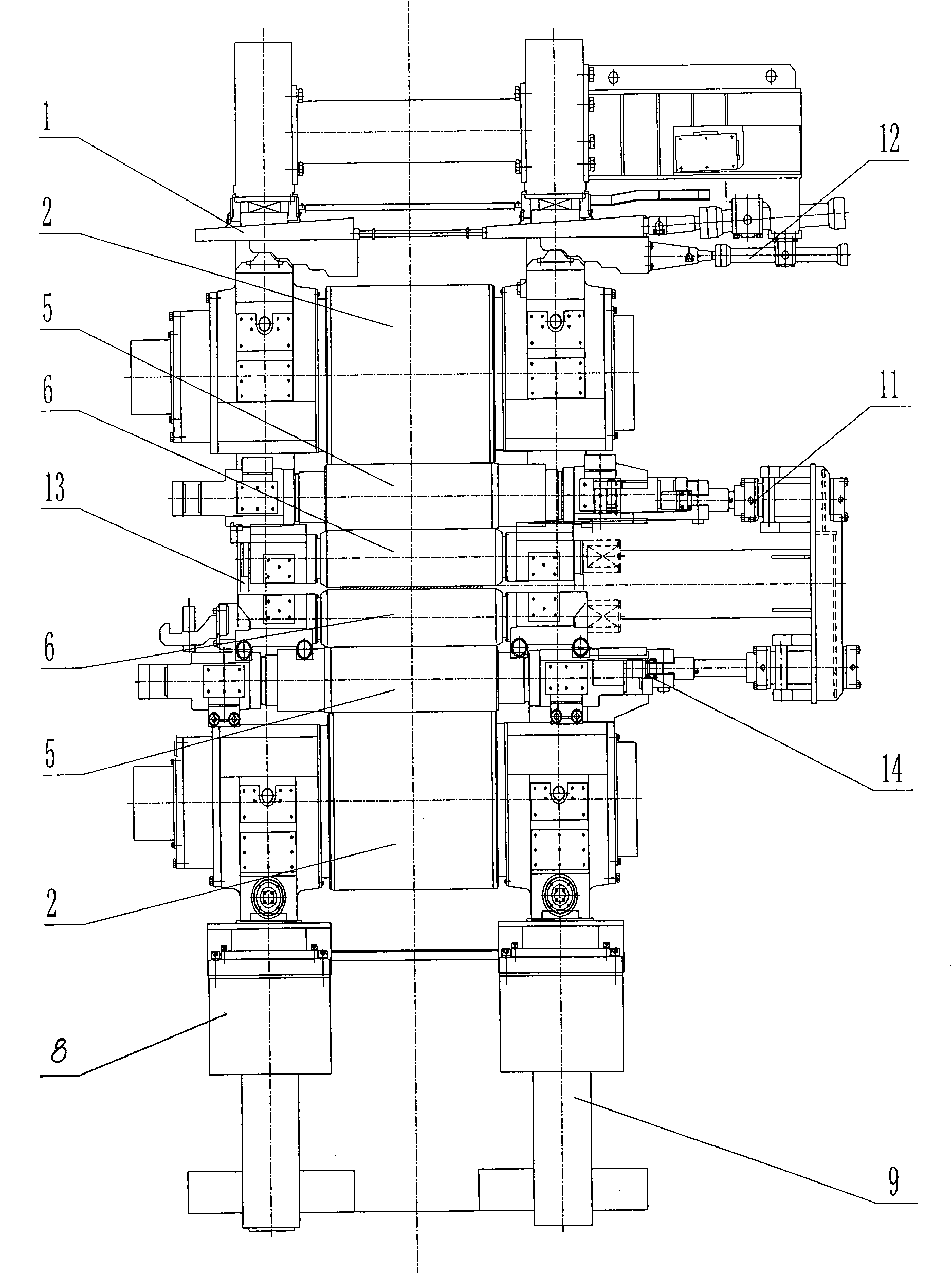

[0012] According to attached Figure 1-3 The present invention is described further:

[0013] The archway 9 constitutes a closed frame structure, and the roll system compensation device 1, backup roll 2, backup roll balance device 4, intermediate roll 5, work roll 6, hydraulic roll bending device 7, hydraulic pressure fine-tuning device 8 and roll changing hydraulic pressure The cylinder 10 etc. are installed in the archway 9; the roller system compensation device 1 is installed on the upper part of the archway 9; the axial locking device 3 is connected with the supporting roller 2 and installed on the operating side of the upper and lower parts of the archway 9; the supporting roller balancing device 4 is connected with the upper support roll 2 and installed in the middle of the archway 9; the middle roll 5 is respectively installed between the support roll 2 and the work roll 6; the hydraulic pressure fine-tuning device 8 is installed at the bottom of the archway 9 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com