Rolling mill SONY magneto-scale online redundancy method

A technology of magnetic ruler and rolling mill, which is applied in the field of online redundancy of SONY magnetic ruler in rolling mills, and can solve problems such as threats to the safe operation of SONY magnetic ruler, long time-consuming, failure of SONY magnetic ruler, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

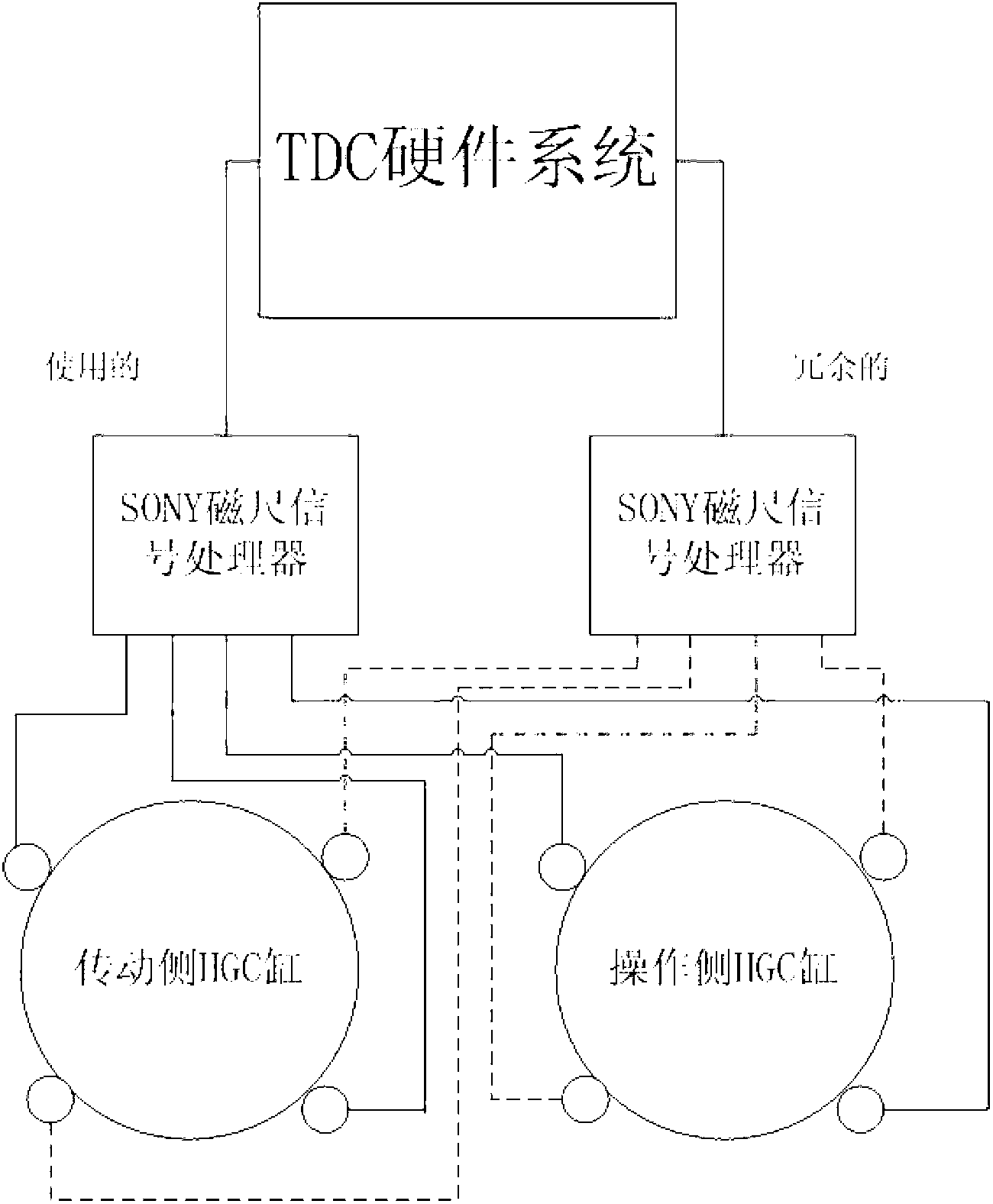

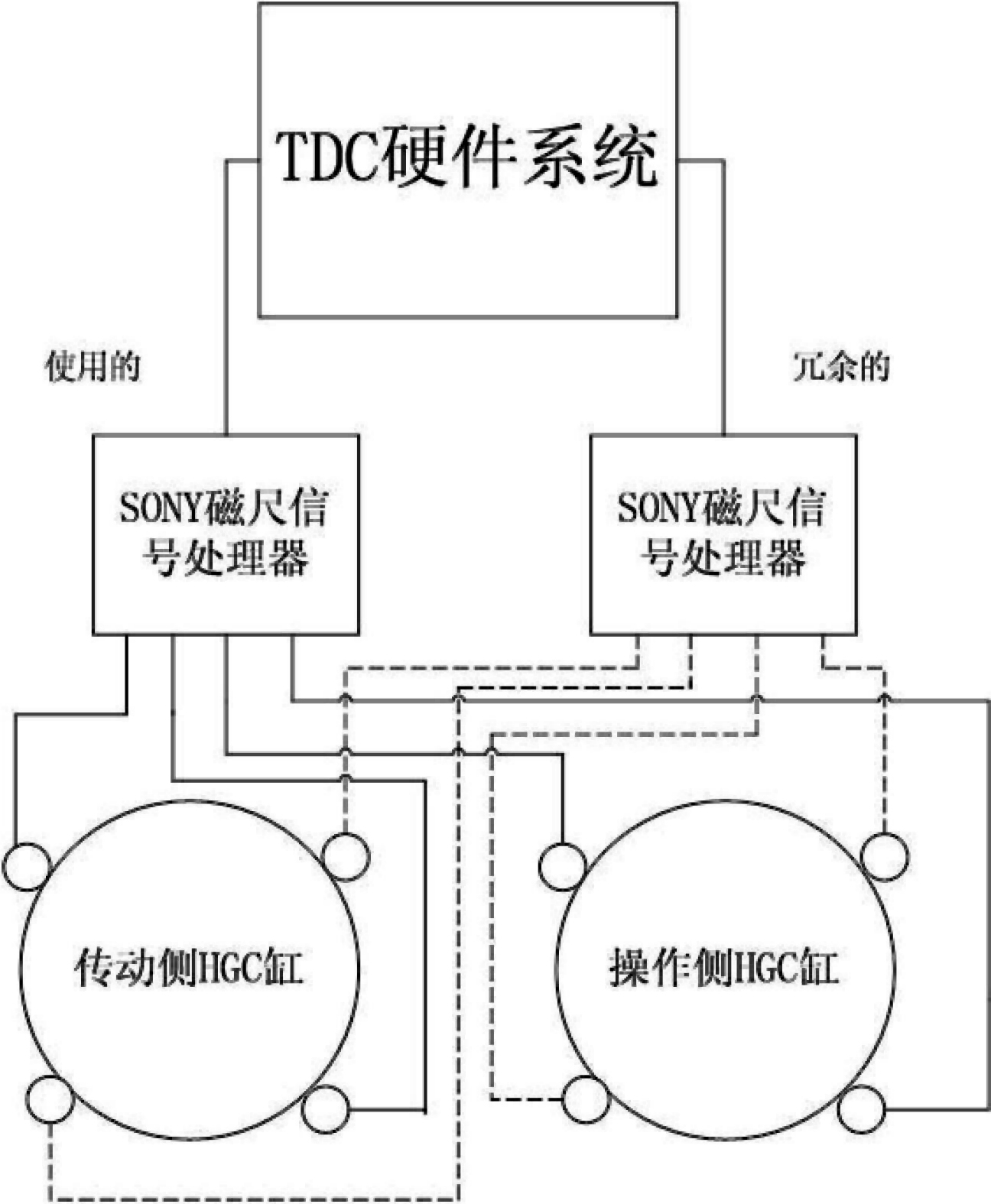

[0018] figure 1 , 2 As a specific embodiment of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The equipment part of the method for online redundancy of the SONY magnetic ruler of a rolling mill comprises: a SONY magnetic ruler, a SONY magnetic ruler signal receiver, and a special cable for the SONY magnetic ruler.

[0020] Implementation example:

[0021] 1. Prepare the equipment and materials required by the present invention, and simultaneously select the installation position of the redundant SONY magnetic ruler.

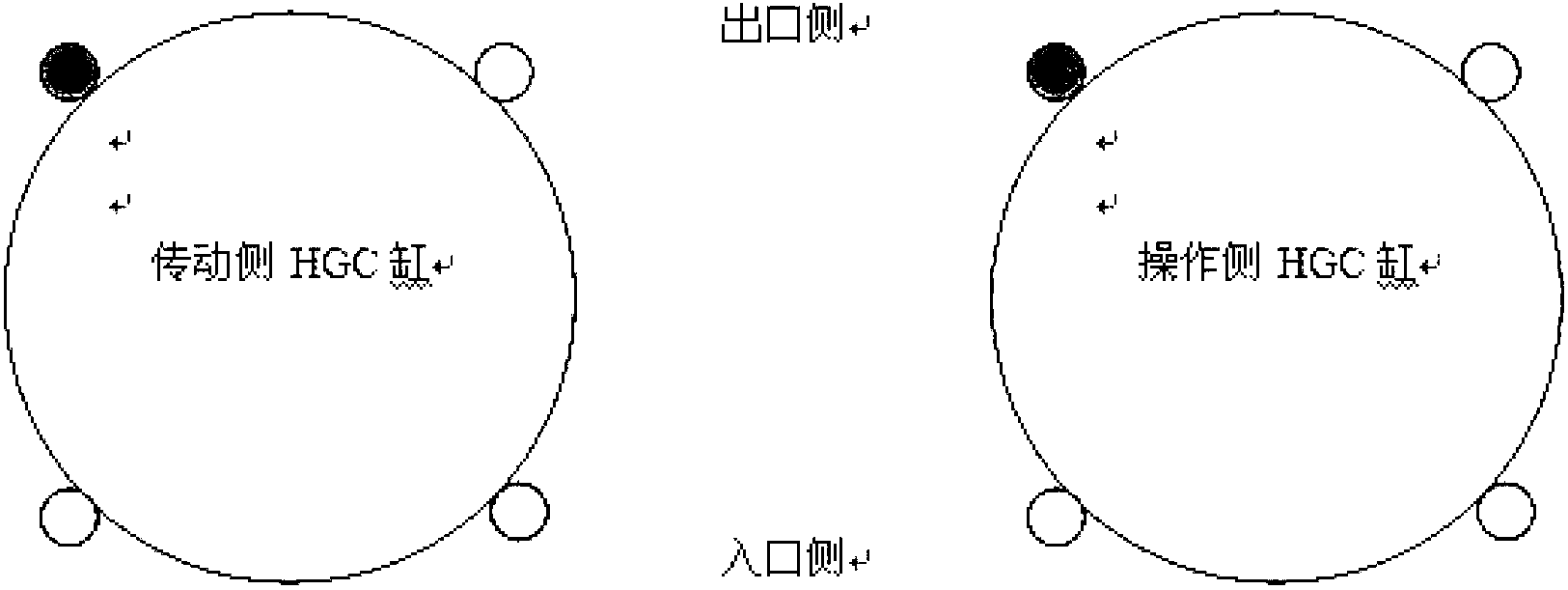

[0022] 2. Install 2 SONY magnetic rulers on the diagonal as redundancy on each HGC cylinder, and take the average value as the actual position of the HGC cylinder.

[0023] 3. Using the original TDC control system, its installation location is in the TDC automation control cabinet in the 3# electrical room. Add a SONY magnetic ruler signal processor in the TDC automation con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com