Hot rolling mill rolling control system used for improving rolling accuracy

A technology of control system and hot rolling mill, which is applied in fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of low control precision and inability to realize constant roll gap rolling, and achieve rolling Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

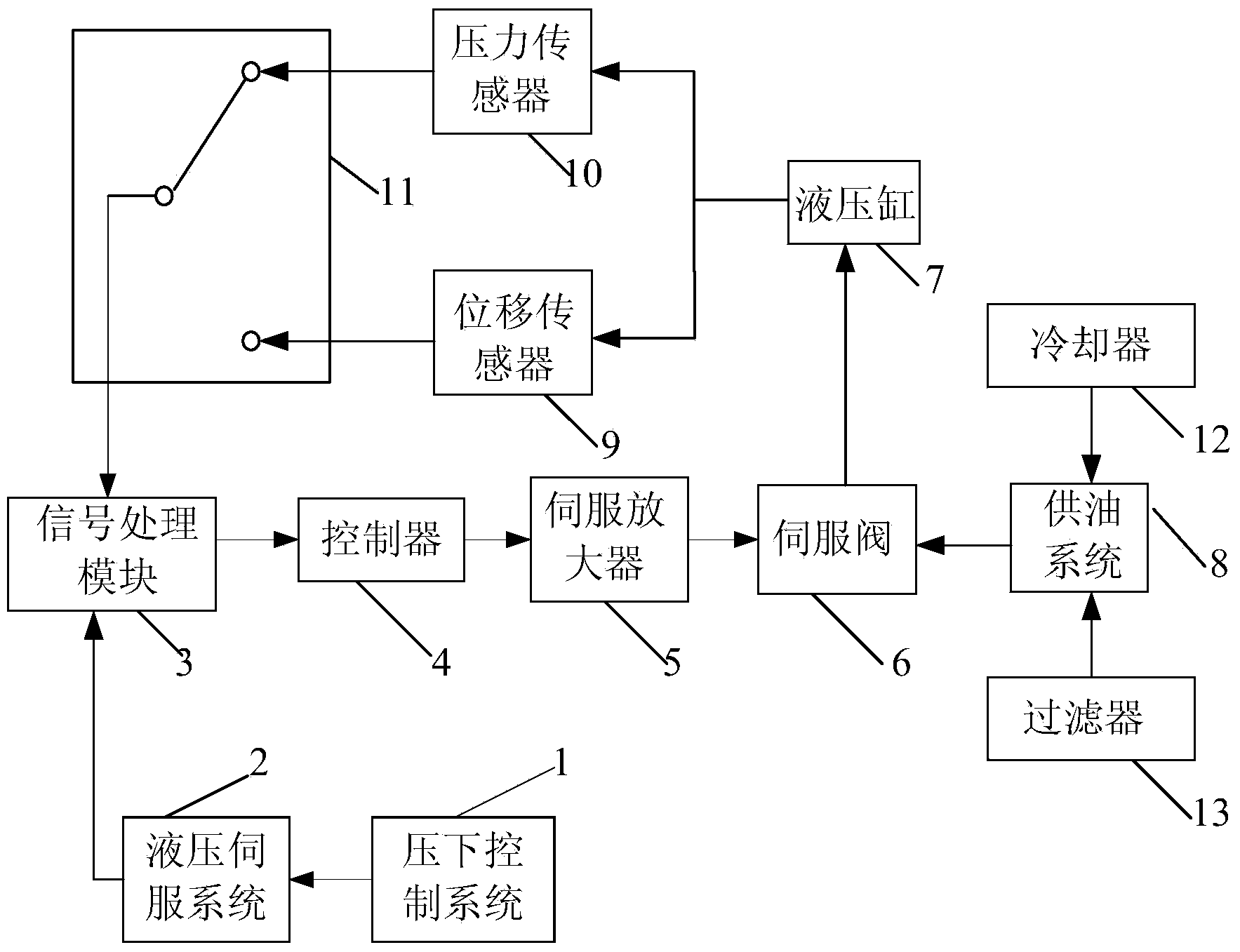

[0019] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail. A hot rolling mill rolling control system for improving rolling precision described in this embodiment includes: a reduction control system 1, a hydraulic servo system 2, a signal processing module 3, and a controller 4. Servo amplifier 5, servo valve 6, hydraulic cylinder 7, oil tank 8 and displacement sensor 9;

[0020] The displacement feedback signal output end of the displacement sensor 9 is connected to the feedback signal input end of the signal processing module 3; the control signal output end of the depression control system 1 is connected to the control signal input end of the hydraulic servo system 2, and the control signal output end of the hydraulic servo system 2 Connect the control signal input terminal of the signal processing module 3, the signal processing module 3 is used to process the signal it receives to obtain the displacement difference, and the difference s...

specific Embodiment approach 2

[0024] Embodiment 2: The rolling control system of a hot rolling mill for improving rolling precision described in Embodiment 1 is further described. In this embodiment, it also includes: a pressure sensor 10 and a switch 11;

[0025] The displacement feedback signal output end of the displacement sensor 9 is connected to a feedback signal input end of the switch 11, the pressure feedback signal output end of the pressure sensor 10 is connected to the other feedback signal input end of the switch 11, and the feedback signal output end of the switch 11 is connected to The feedback signal input end of the signal processing module 3 ; the pressure sensor 10 is used to detect the pressure in the hydraulic cylinder 7 .

[0026] A rolling control system for a hot rolling mill used to improve rolling precision is working. When the switch 11 connects the pressure sensor 10 to the signal processing module 3, the pressing control system 1 sends a pressure to the hydraulic servo system 2....

specific Embodiment approach 3

[0027] Embodiment 3: According to Embodiment 1, a rolling control system for hot rolling mills for improving rolling precision will be further described. In this embodiment, it also includes: cooler 12, which is used for Yu is cooling the oil in the oil tank 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com