Rolling device

A technology of rolling and pressing rollers, applied in the field of rolling devices, can solve the problems of different elongation, easy wrinkling, uneven winding of pole pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The rolling device of the present invention will be described in detail below with reference to the accompanying drawings.

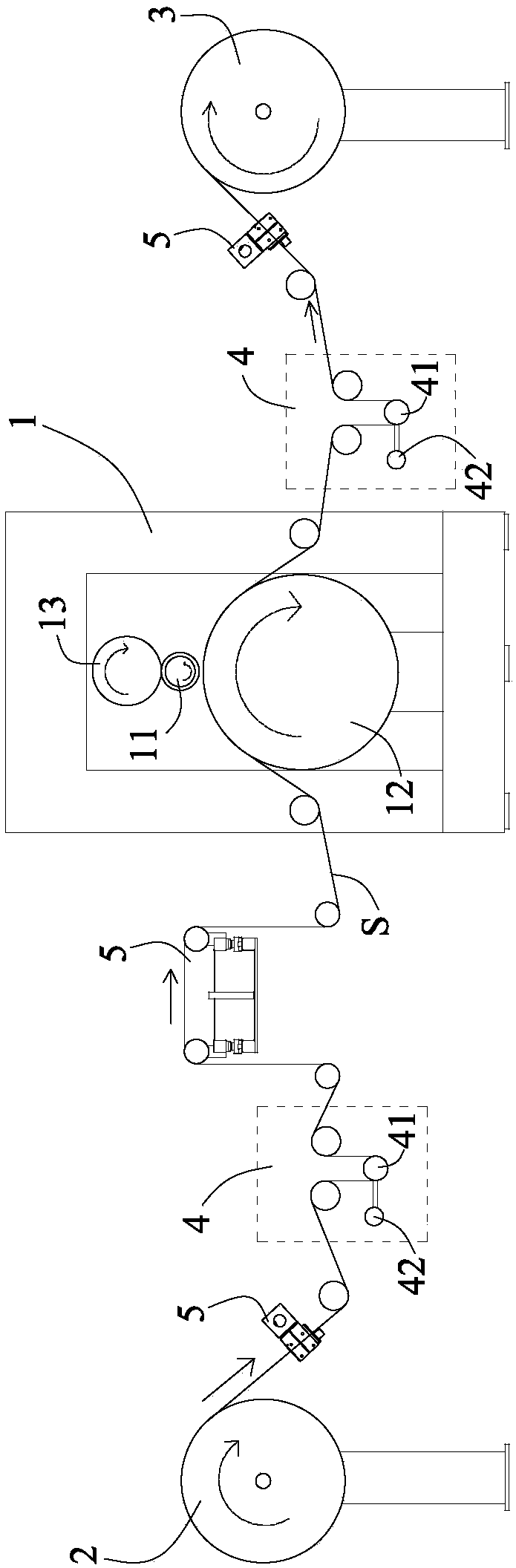

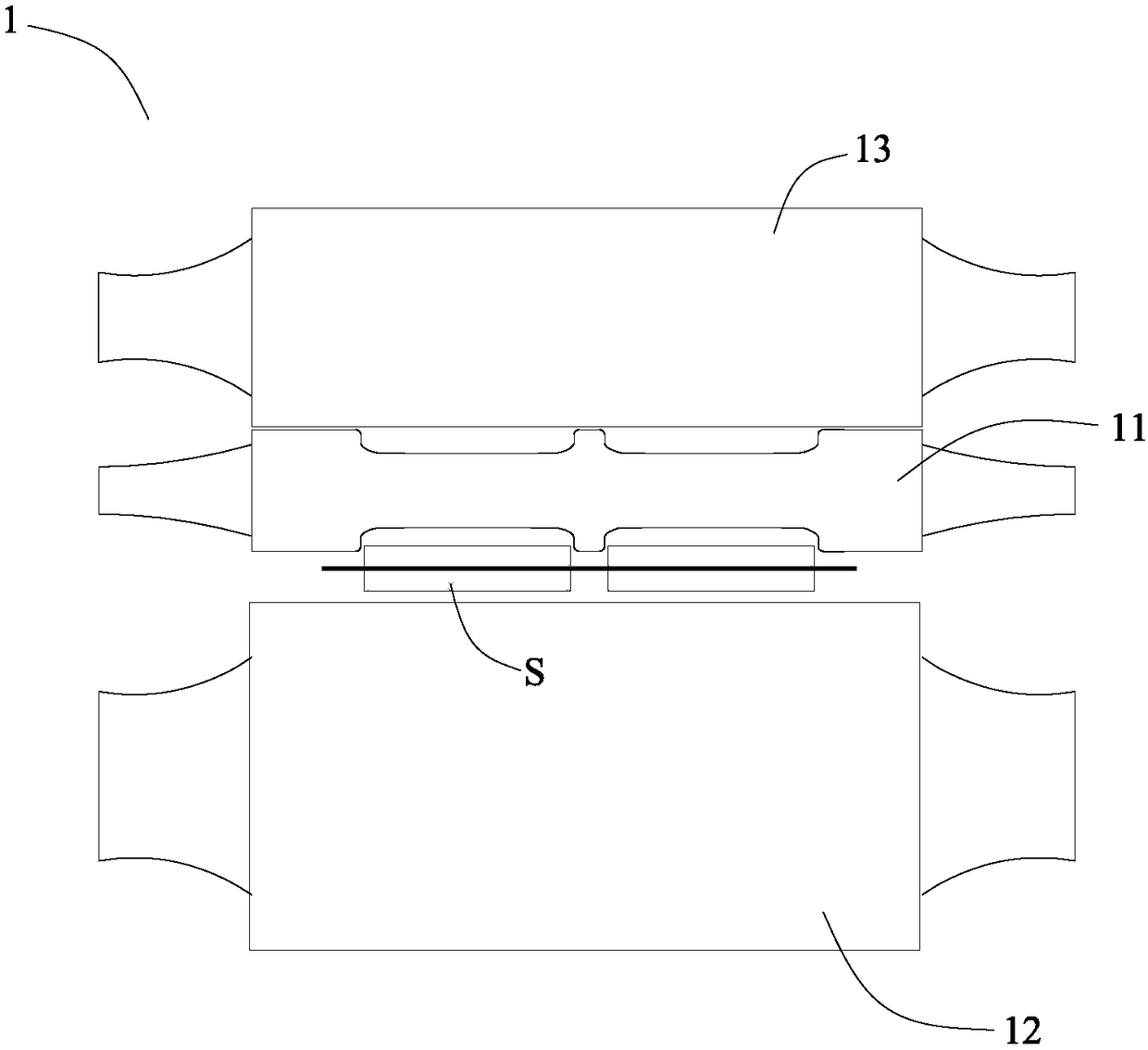

[0028] refer to Figure 1 to Figure 9 , the rolling device according to the present invention includes a rolling mechanism 1 for rolling a strip S, and the rolling mechanism 1 includes a first pressing roller 11 and a second pressing roller 12 disposed opposite to each other. The strip S comprises a base material S1 and a coating layer S2. The base material S1 has an exposed blank area S11 and a coverage area S12 covered by the coating layer S2; both the blank area S11 and the coverage area S12 extend longitudinally and alternately along the transverse direction.

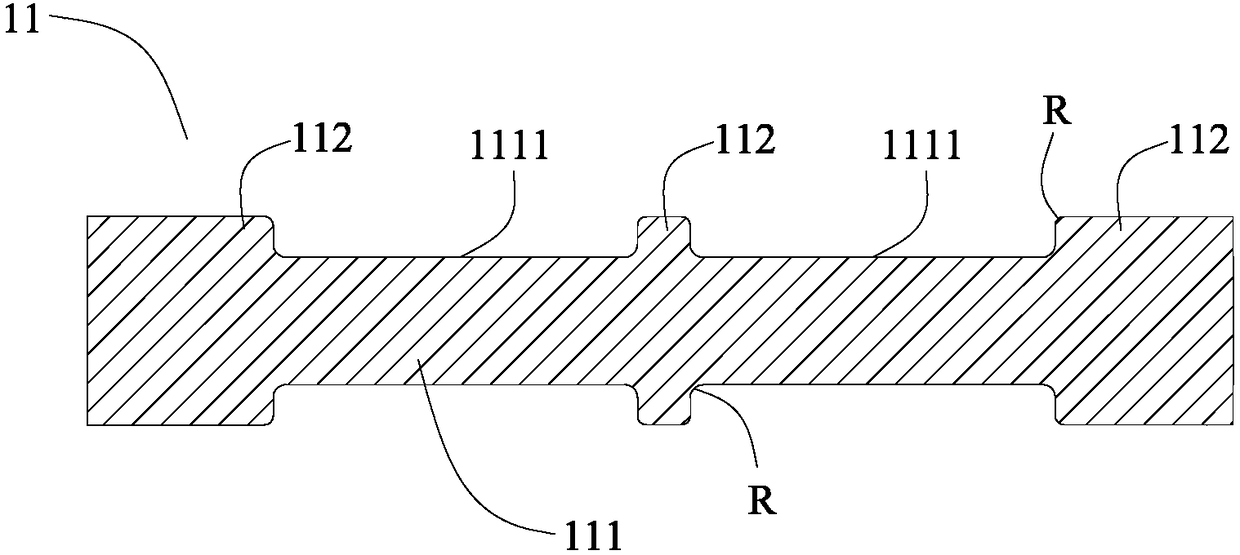

[0029] The roll diameter of the second press roll 12 is larger than the roll diameter of the first press roll 11 . The first pressing roller 11 has: a roller body 111 with an annular rolling nip 1111 formed on its outer peripheral surface; Among them, the rolling area 1111 and the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com