Universal rolling device of ball flat steel and rolling method

A universal rolling and bulbous flat steel technology, which is applied in metal rolling, metal rolling, metal rolling racks, etc., can solve the problems of fast wear of the pass, large consumption of rolls, and only small batch production, etc., to achieve Less consumption of rolls, high rolling precision, and the effect of increasing rolling batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

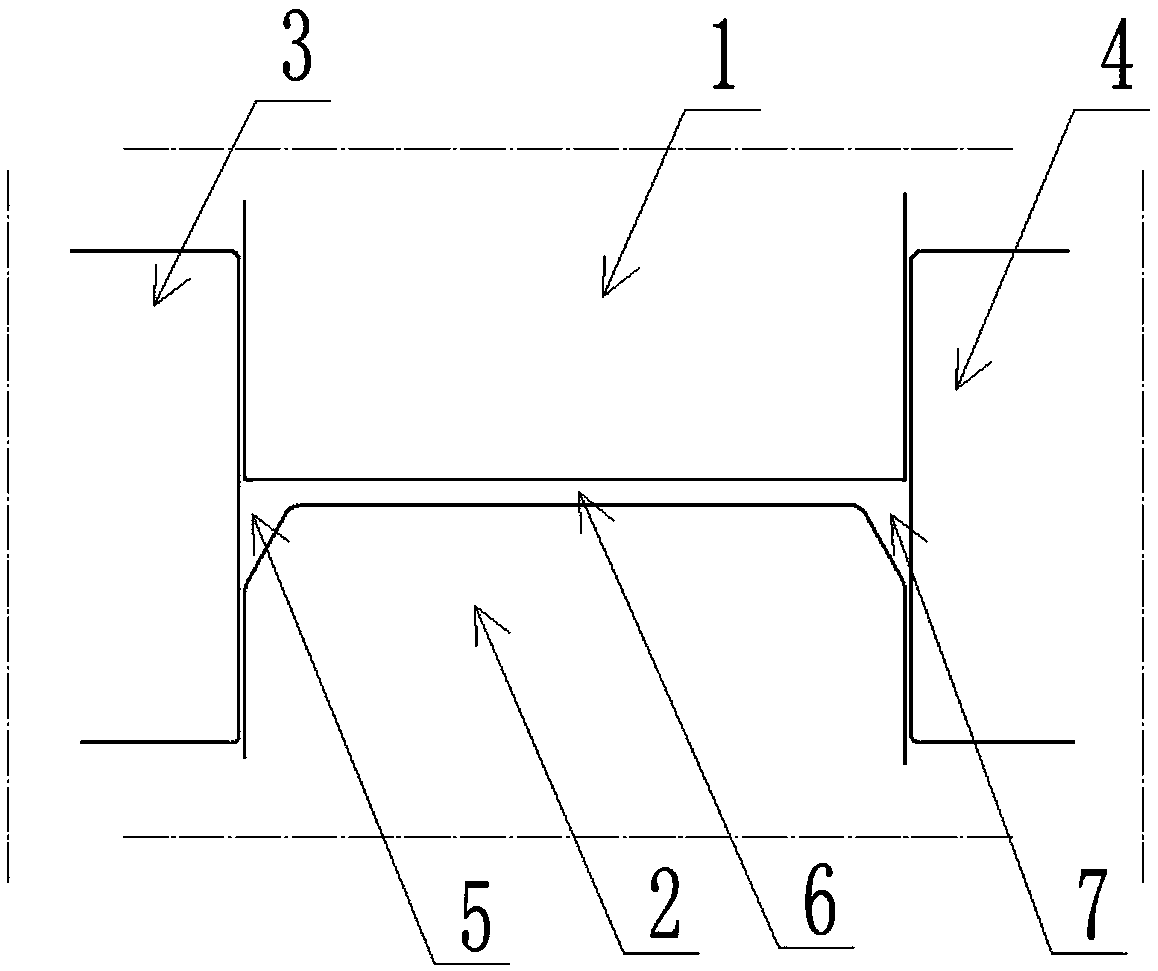

[0018] A universal rolling device for bulbous flat steel, the universal rolling device comprises a universal rolling mill unit, the universal rolling mill unit is composed of 3-6 universal rolling mills, any universal rolling mill has an upper horizontal roll 1, a lower horizontal roll 2, The operation side vertical roller 3 and the transmission side vertical roller 4; the two ends of the lower horizontal roller 2 are chamfered, so that the upper horizontal roller 1, the lower horizontal roller 2, the operation side vertical roller 3 and the transmission side vertical roller 4 are combined together to form Combined flat bulb steel rolling hole, the shape of the combined flat bulb steel rolling hole is the shape of two flat bulb steel combined, the webs of the two flat bulb steel are connected together to form a combined web 6, the ball The heads are respectively located on the same side of the connected web as the left leg 5 and the right leg 7 .

[0019] Left leg 5 is made up...

Embodiment 2

[0021] A universal rolling device for bulbous flat steel, the universal rolling device comprises a universal rolling mill unit, the universal rolling mill unit is composed of 3-6 universal rolling mills, any universal rolling mill has an upper horizontal roll 1, a lower horizontal roll 2, The operation side vertical roller 3 and the transmission side vertical roller 4; the two ends of the lower horizontal roller 2 are chamfered, so that the upper horizontal roller 1, the lower horizontal roller 2, the operation side vertical roller 3 and the transmission side vertical roller 4 are combined together to form Combined flat bulb steel rolling hole, the shape of the combined flat bulb steel rolling hole is the shape of two flat bulb steel combined, the webs of the two flat bulb steel are connected together to form a combined web 6, the ball The heads are respectively located on the same side of the connected web as the left leg 5 and the right leg 7 .

[0022] Left leg 5 is made up...

Embodiment 3

[0024] A universal rolling device for bulbous flat steel, the universal rolling device comprises a universal rolling mill unit, the universal rolling mill unit is composed of 3-6 universal rolling mills, any universal rolling mill has an upper horizontal roll 1, a lower horizontal roll 2, The operation side vertical roller 3 and the transmission side vertical roller 4; the two ends of the lower horizontal roller 2 are chamfered, so that the upper horizontal roller 1, the lower horizontal roller 2, the operation side vertical roller 3 and the transmission side vertical roller 4 are combined together to form Combined flat bulb steel rolling hole, the shape of the combined flat bulb steel rolling hole is the shape of two flat bulb steel combined, the webs of the two flat bulb steel are connected together to form a combined web 6, the ball The heads are respectively located on the same side of the connected web as the left leg 5 and the right leg 7 .

[0025]Left leg 5 is made up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com