Quick-opening device of airflow dyeing machine

A technology of air flow dyeing machine and door opening device, which is applied in the direction of liquid/gas/steam jet propulsion fabric, textile material contact outlet textile material processing, textile material container processing, etc., which can solve the problem of slow speed, no safety interlock device, Unsafe and other issues, to achieve the effect of fast speed and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

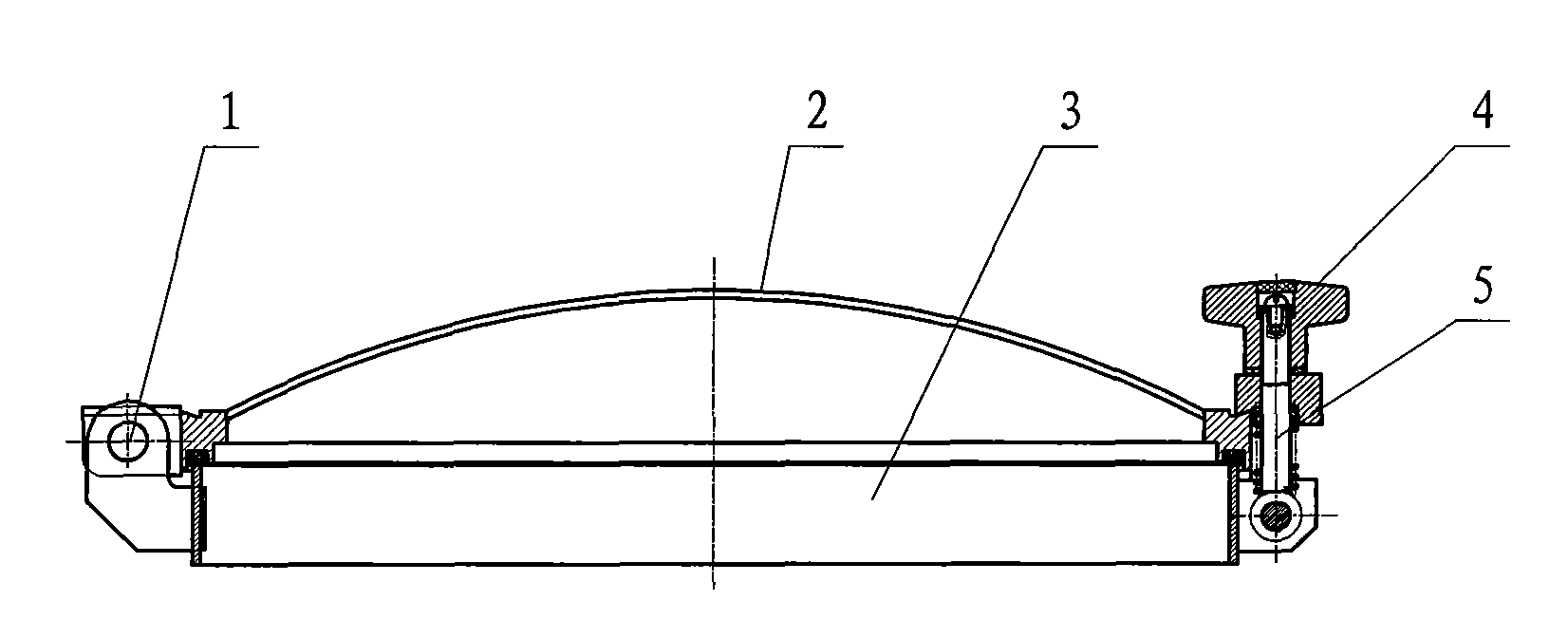

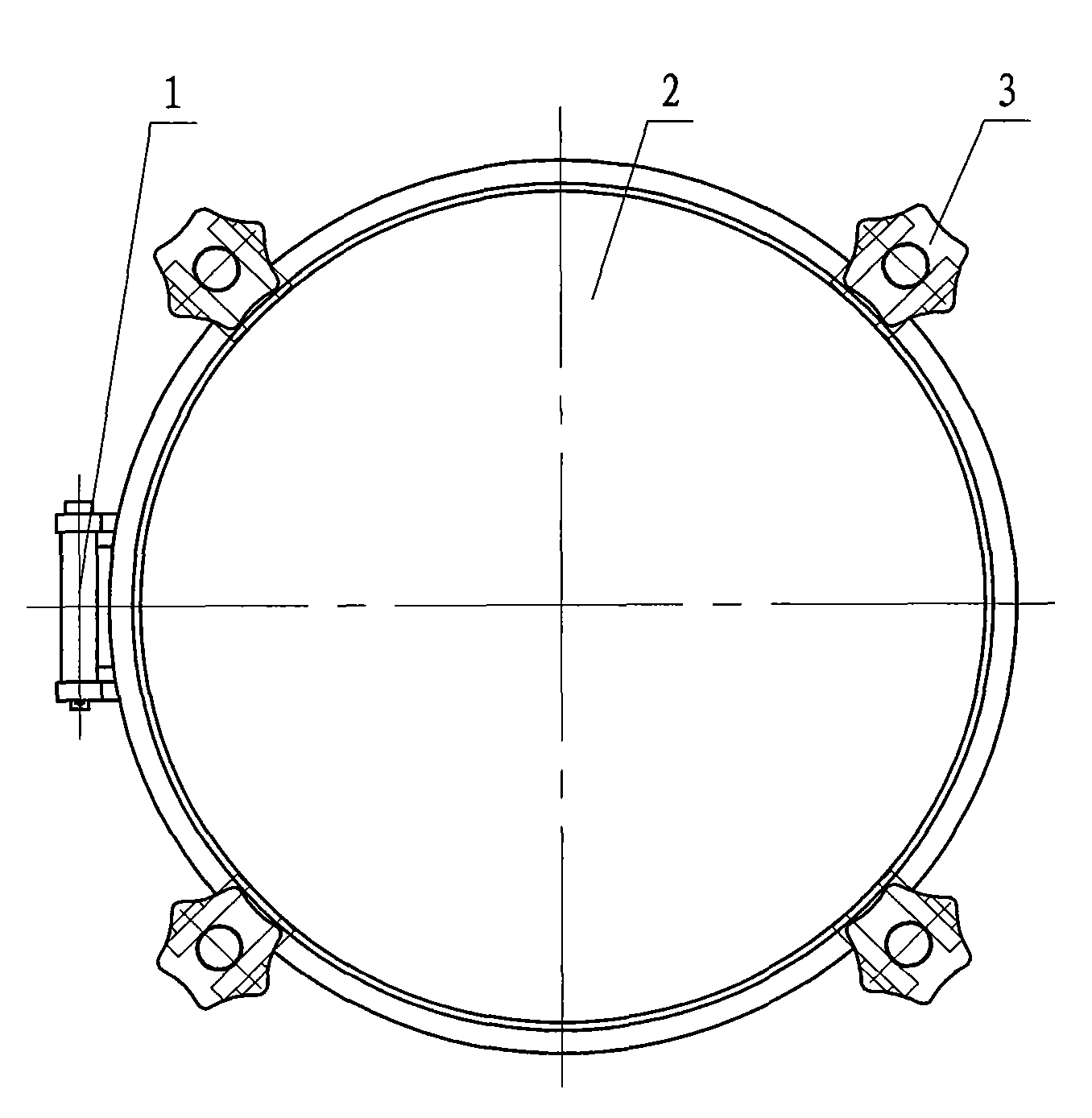

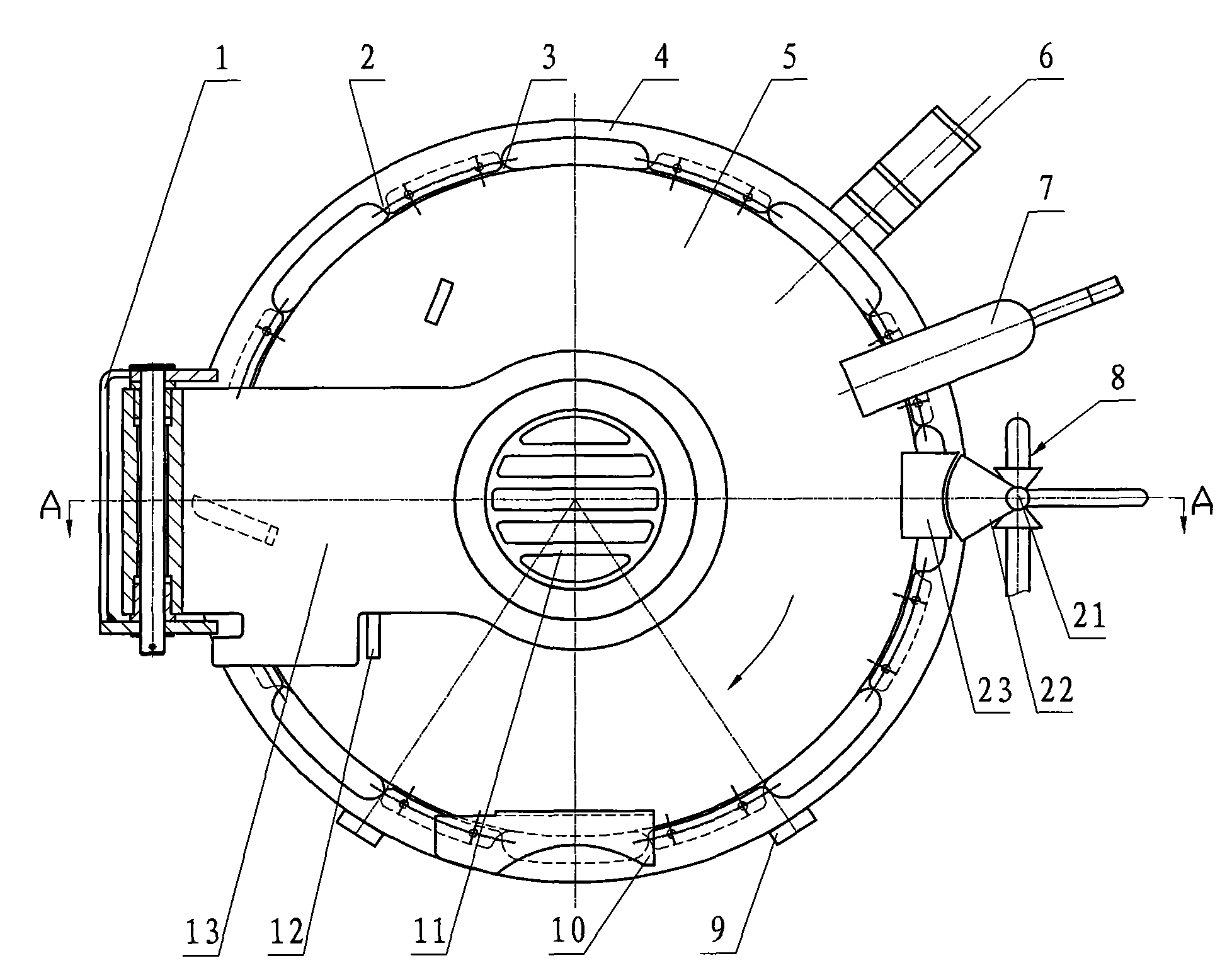

[0012] Such as image 3 , Figure 4 As shown, the present invention is a quick-opening device for an airflow dyeing machine, which includes a manhole flange 4 and a manhole cover 5, and the manhole flange 4 is welded on the cylinder body 20 of the dyeing machine. A door knocker 13 is hinged with a hinge 1 on the manhole flange 4 , and the manhole cover 5 is rotatably mounted on the door knocker 13 . The manhole cover 5 is provided with a handle 7, and the manhole cover 5 can be rotated by pulling the handle 7. The inner wall of the manhole flange 4 is provided with internal teeth 2, and the outer wall of the manhole cover 5 is provided with external teeth 3, the number of internal teeth 2 and external teeth 3 is equal, and the manhole cover 5 cooperates with the internal teeth 2 and external teeth 3 The rotation is clamped in the flange 4 of the manhole. The opening and closing of this toothed structure only needs to turn one tooth position, which is easy to operate. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com