A safety interlock method and interlock device for pipe end beveling machine

A safety interlocking and beveling machine technology, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of danger and high speed of cutter head, achieve low production cost, convenient installation and adjustment, and improve the safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

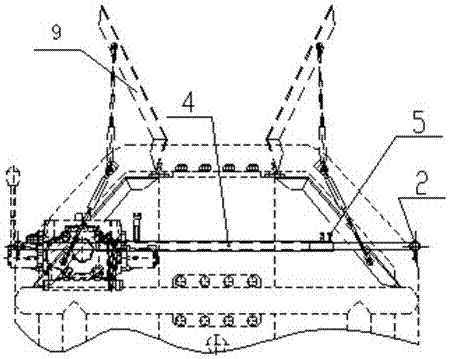

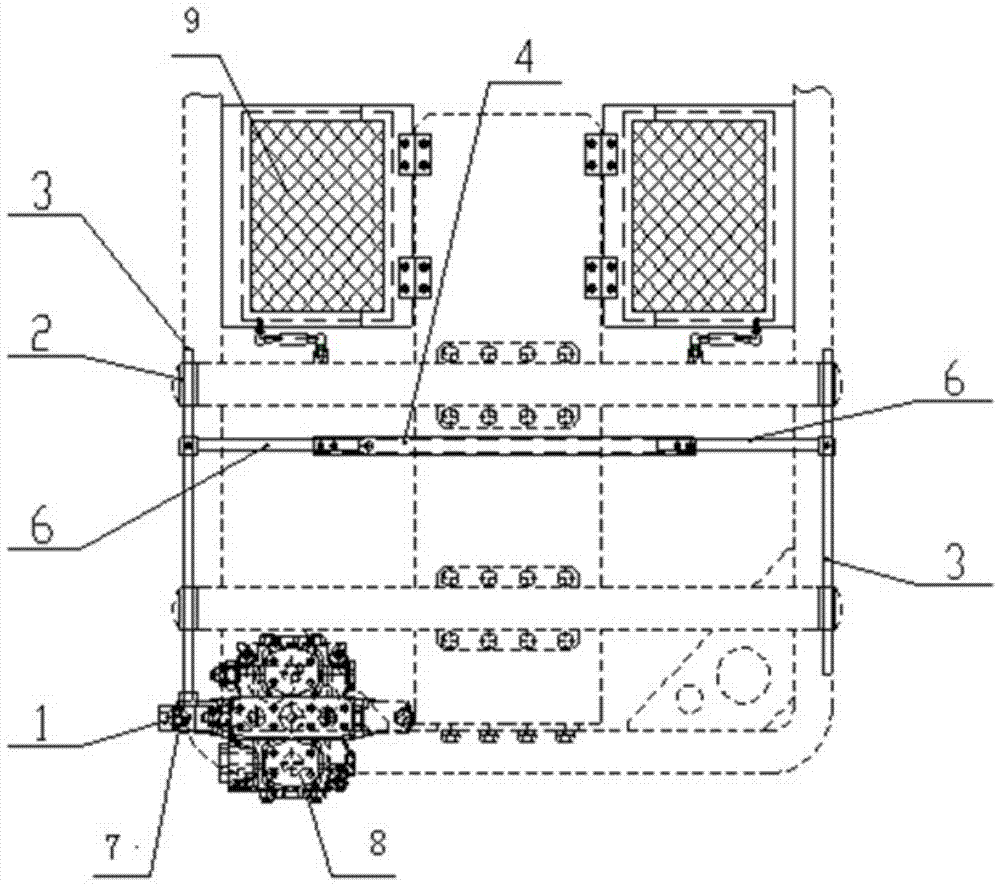

[0015] Such as figure 1 , 2 As shown, a safety interlock device for pipe end beveling machine consists of handle limit block (1), positioning sleeve (2), lock pin (3), connecting sleeve (4), screw (5 ), sliding sleeve connecting rods (6), one end of the two sliding sleeve connecting rods (6) is respectively connected to the two ends of the connecting sleeve (4) by screws, and the other end of the two sliding sleeve connecting rods (6) One end is respectively worn on the lock pins (3) on both sides, and the lock pins (3) on both sides are respectively worn on the positioning sleeve (2) fixed on the frame; the lock on the side of the cutter head rotary switch valve (8) One end of the pin (3) corresponds to the limit hole of the handle limit block (1) of the switch valve handle (7); the other end of the lock pin (3) on the side of the cutter head rotary switch valve (8) corresponds to the protective door (9) .

[0016] A safety interlocking method for a pipe end beveling machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com